Method for converting ammonium thiocyanate into potassium thiocyanate

A technology for converting ammonium thiocyanate into sulfur and potassium thiocyanate, which is applied in the direction of thiocyanate, etc., and can solve the problems of inconvenient preparation and unsuitability for enterprise production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

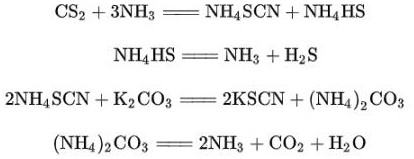

[0012] as Figure 1 shown;

[0013] A method of converting ammonium thiocyanate to potassium thiocyanate, including the following steps, using carbon dioxide and ammonia water for pressurized synthesis reaction, producing ammonium thiocyanate and ammonium sulfide, and then decomposing ammonium sulfide into hydrogen sulfide by desulfurization evaporation, and slowly adding potassium carbonate solution at liquid temperature of 100 ° C, that is, generating potassium thiocyanate.

[0014] As a method of converting ammonium thiocyanate to potassium thiocyanate is preferred in the present invention, a large amount of carbon dioxide and ammonia will be generated during the reaction, and ammonia can be recycled.

[0015] As a method of converting ammonium thiocyanate into potassium thiocyanate is preferred, the reaction solution is filtered to remove the intolerable for evaporation, and then cooled, crystallized, centrifuged to obtain potassium thiocyanate.

[0016] Physical

[0017] Prop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com