A perovskite solar cell doped with potassium thiocyanate and a preparation method thereof

A technology of solar cells and potassium thiocyanate, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as many defects, large hysteresis effect of batteries, and poor crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

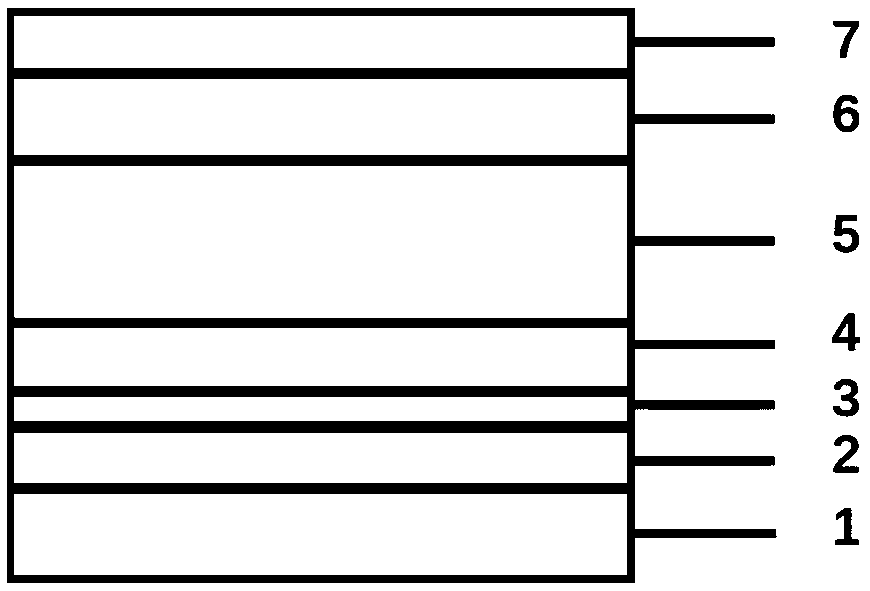

[0042] Step 1. Clean FTO conductive glass: choose FTO conductive glass with a square resistance of 14Ω, a light transmittance of 90%, and a thickness of 2.2mm as the base material, and use detergent solution, deionized water, ethanol, acetone, and isopropyl in sequence Alcohol was cleaned in an ultrasonic machine for 30 minutes, and then treated with an ultraviolet ozone cleaner for 15 minutes to obtain FTO conductive glass with a clean surface.

[0043] Step 2. Preparation of TiO 2 Precursor liquid and preparation of TiO 2 Dense layer: Dilute 369 microliters of isopropyl titanate solution into 2.53 milliliters of isopropanol, then dilute 35 microliters of hydrochloric acid solution (2M concentration) into 2.53 milliliters of isopropanol, and finally dilute the two The two solutions were mixed and stirred for a long time to obtain TiO 2 Precursor fluid; the prepared TiO 2 The precursor liquid was spin-coated on the FTO under the parameter of "3000 rpm for 30 seconds", and h...

Embodiment 2

[0052] Step 1, cleaning the FTO conductive glass: same as Step 1 in Example 1.

[0053] Step 2. Preparation of TiO 2 Precursor liquid and preparation of TiO 2 Dense layer: same as Step 2 in Example 1.

[0054] Step 3. Preparation of TiO 2 Mesoporous layer: same as Step 3 in Example 1.

[0055] Step 4, preparing potassium thiocyanate solution: same as step 4 in Example 1.

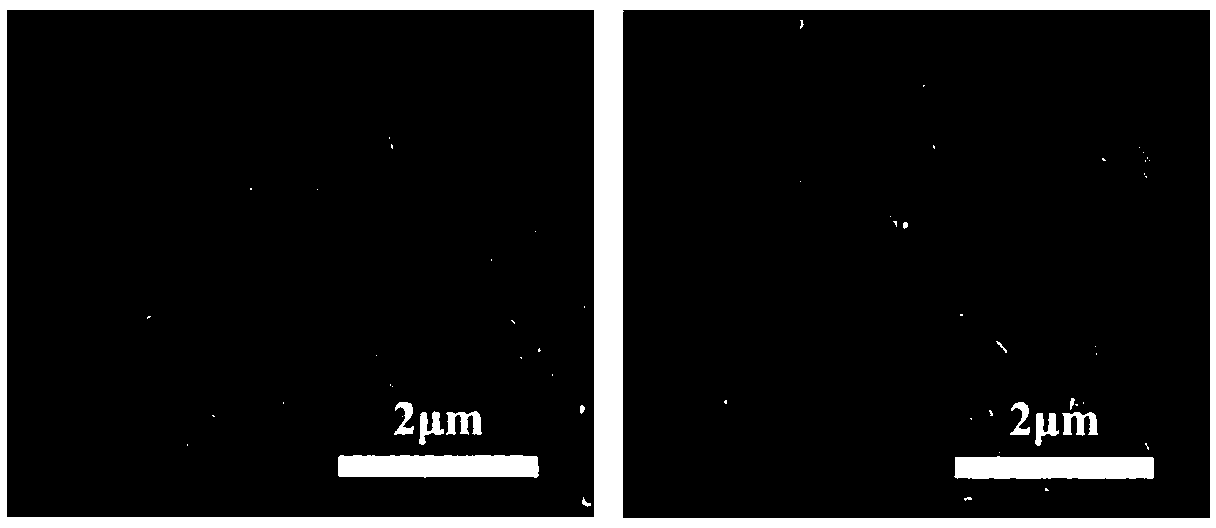

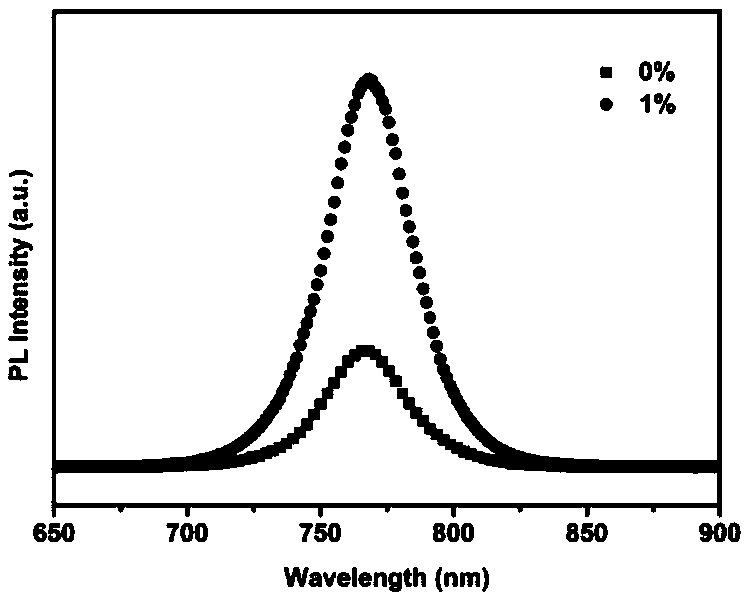

[0056] Step five, preparation of potassium thiocyanate-doped perovskite precursor fluid: lead iodide (PbI 2 ), methylamine iodide (MAI) and dimethyl sulfoxide (DMSO) were dissolved in dimethylformamide (DMF) solution at a molar ratio of 1:1:1, so that their concentration was 1.4mol / ml, and then The solution was stirred at 40 °C for 1 hour to obtain a clear and transparent yellow perovskite precursor liquid. 14 microliters of the prepared potassium thiocyanate solution was added to 1 ml of the perovskite precursor solution to obtain a 1% (molar ratio) potassium thiocyanate-doped perovskite precursor sol...

Embodiment 3

[0062] Step 1, cleaning the FTO conductive glass: same as Step 1 in Example 1.

[0063] Step 2. Preparation of TiO 2 Precursor liquid and preparation of TiO 2 Dense layer: same as Step 2 in Example 1.

[0064] Step 3. Preparation of TiO 2 Mesoporous layer: same as Step 3 in Example 1.

[0065] Step 4, preparing potassium thiocyanate solution: same as step 4 in Example 1.

[0066] Step five, preparation of potassium thiocyanate-doped perovskite precursor fluid: lead iodide (PbI 2 ), methylamine iodide (MAI) and dimethyl sulfoxide (DMSO) were dissolved in dimethylformamide (DMF) solution at a molar ratio of 1:1:1, so that their concentration was 1.4mol / ml, and then The solution was stirred at 40 °C for 1 hour to obtain a clear and transparent yellow perovskite precursor liquid. 28 microliters of the prepared potassium thiocyanate solution was added to 1 ml of the perovskite precursor solution to obtain a 2% (molar ratio) potassium thiocyanate-doped perovskite precursor sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com