Oil removal system and method for high-concentration oily sewage

An oily sewage, high concentration technology, applied in water/sewage treatment, chemical instruments and methods, water/sewage multi-stage treatment, etc., can solve problems such as low oil-water separation efficiency, and achieve the effect of improving oil-water separation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

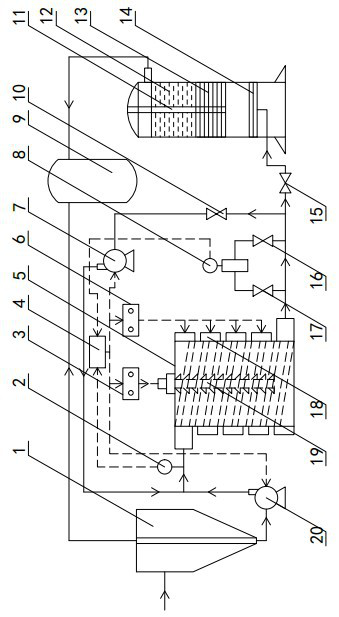

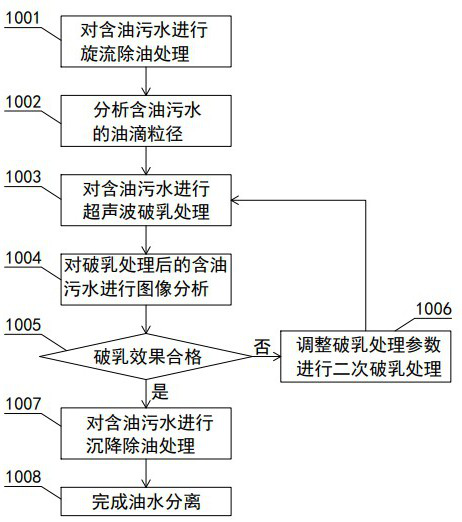

[0035] Such as figure 1As shown, a degreasing system for high-concentration oily sewage (hereinafter referred to as the degreasing system) includes a cyclone degreasing device 1, an ultrasonic demulsification reactor 5 and a corrugated degreasing device 13 placed in sequence. The oily sewage is connected to the inlet of the cyclone degreaser 1 through the pipeline. The oily sewage is introduced into the cyclone degreaser from the tangential inlet at relative pressure or speed, and the oily sewage runs at high speed in the cyclone degreaser 1 to form a centrifugal force field. Under the effect of centrifugal force, the relatively dense water is thrown to the surroundings, and moves downward toward the wall, and finally is discharged from the drain at the bottom and connected to the inlet of the water inlet pump 20 through a pipeline; the less dense oil migrates to It operates in the middle and upwards, and finally discharges from the overflow port in the center, and is connect...

Embodiment 2

[0073] The difference between this embodiment and Embodiment 1 is that in this embodiment, the parameters in the oil-water separation process of oily sewage are different. In this embodiment, the oily sewage with a petroleum content of 2000mg / L enters the cyclone degreaser 1, and the water flow rate is 6m 3 / h, the working pressure inside the cyclone degreaser 1 is 0.7MPa, and the oil droplet size of the effluent is 5~10μm after testing. At this time, the power of the low-frequency adjustable ultrasonic generator 3 is 150w, and the output frequency of the ultrasonic wave is 20kHz; the power of the high-frequency adjustable ultrasonic generator 6 is 150w, and the output frequency of the ultrasonic wave is 60kHz.

[0074] Now in the ultrasonic demulsification reactor 5, the ultrasonic transducer rod 19 is alternately operated by the transducer tool head of 20kHz and 40kHz, and the ultrasonic transducer 18 works at 80kHz and 60kHz, and the reaction time in the reactor is 15min ,...

Embodiment 3

[0076] The difference between this embodiment and Embodiment 1 is that in this embodiment, the parameters in the oil-water separation process of oily sewage are different. In this embodiment, the oily sewage with a petroleum content of 800mg / L enters the cyclone degreaser 1, and the water flow rate is 5m 3 / h, the working pressure inside the cyclone degreaser 1 is 1.0MPa, and the oil droplet size of the effluent is 1~2μm after testing. At this time, the power of the low-frequency adjustable ultrasonic generator 3 is 300w, and the output frequency of the ultrasonic wave is 20kHz. The power of the high-frequency adjustable ultrasonic generator 6 is 70w, and the output frequency of the ultrasonic wave is 60kHz.

[0077] Now in the ultrasonic demulsification reactor 5, the ultrasonic transducer rod 19 works alternately by the transducer tool head of 30kHz and 40kHz, and the ultrasonic transducer 18 works at 100kHz, 80kHz and 60kHz, and the reaction time in the reactor is for 15 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com