Structural flame-retardant polyurethane foam material suitable for heat preservation in buildings of refrigeration houses and ski fields

A polyurethane foam and ski resort technology, applied in the field of polyurethane materials, can solve problems such as difficulty in strength and increased cost of cold storage, and achieve the effect of high cross-linking density, uniform functionality, and low cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

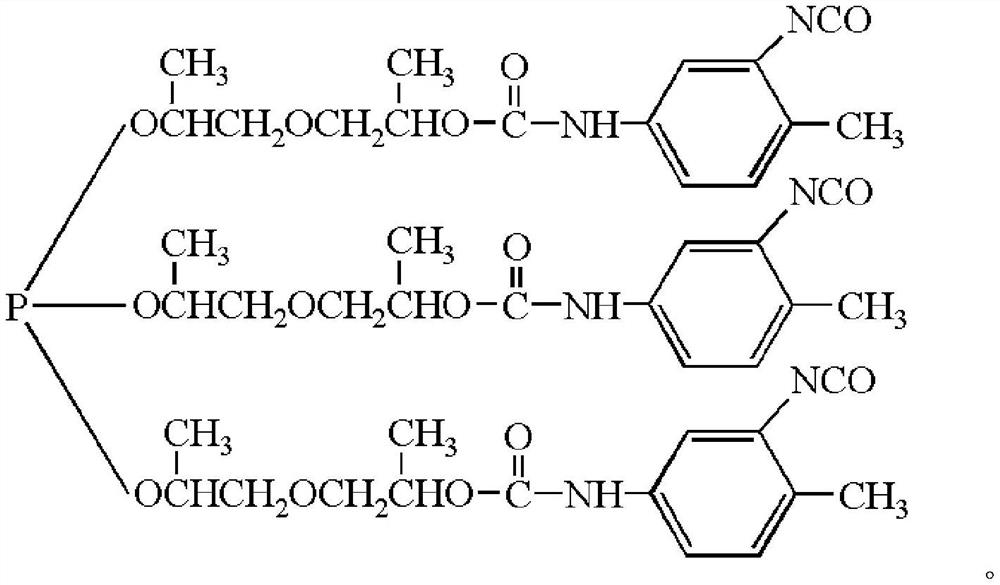

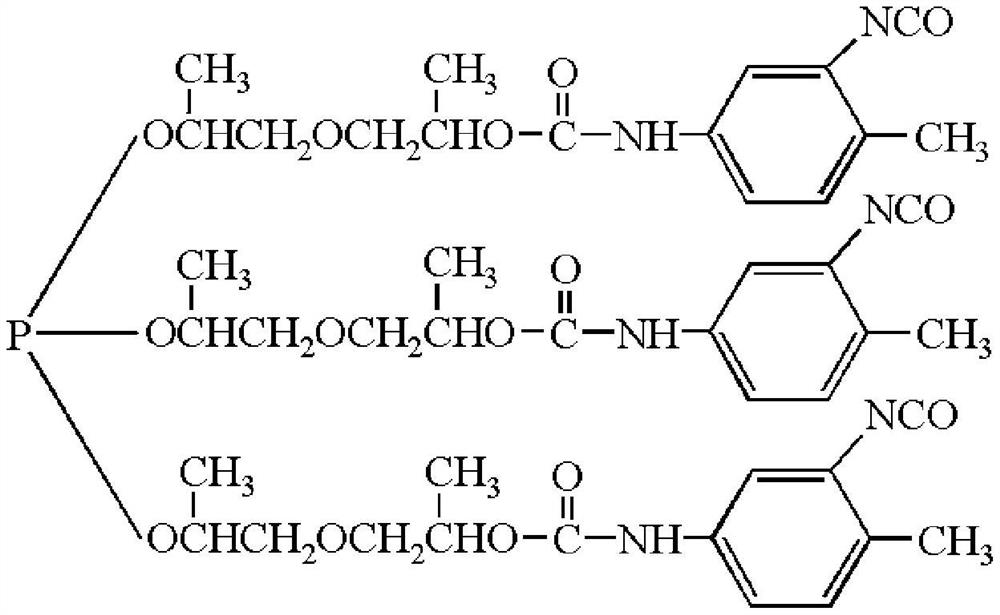

[0041] The structural flame-retardant polyurethane foam material suitable for thermal insulation in cold storage and ski resort buildings in this embodiment is formed by polymerizing isocyanate and polyol. The mass ratio of isocyanate to polyol is (100-150):100, and the isocyanate has a trifunctionality. Modified isocyanate, its chemical structural formula is as follows:

[0042]

[0043] Among them, the P content of the three-functionality modified isocyanate is 3.3%, the N content is 8.8%, and the NCO% content is 13.2%;

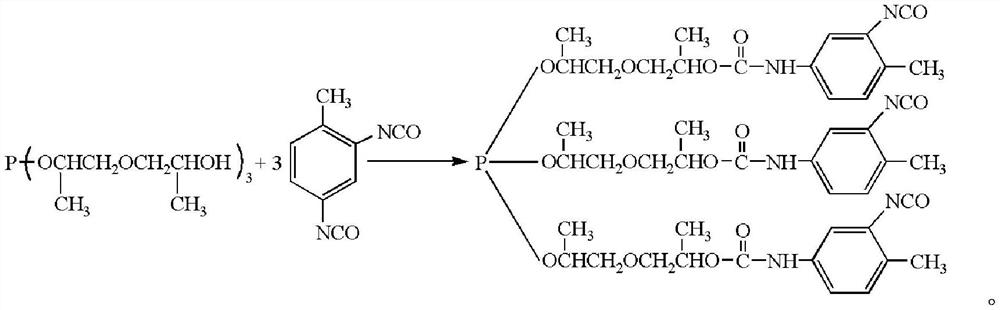

[0044] The synthesis method of the structural flame-retardant polyurethane foam material suitable for the thermal insulation of cold storage and ski resort buildings in this embodiment, the synthesis method is to polymerize the 3-functionality modified isocyanate and polyol, and its special feature is: 3-functionality modified Reactive isocyanate is obtained by polymerization of tris(di-1,2-propanediol) phosphite and TDI, and the reaction equation is as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com