Edge modified graphene, polyolefin composition, polyolefin foaming bead and polyolefin foaming bead forming body

A graphene and polyolefin technology, applied in the field of foamed polyolefin, can solve the problems of high antistatic agent addition, structural damage, poor antistatic performance, etc., and achieve short reaction cycle, low production cost and high antistatic performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

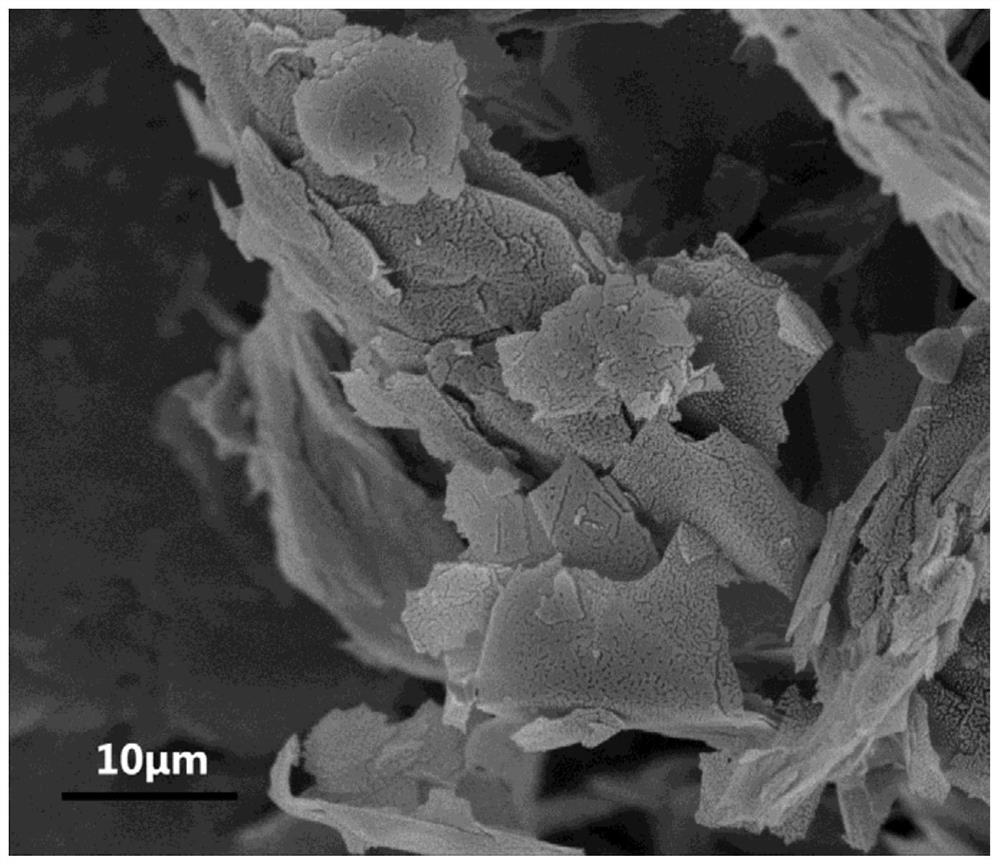

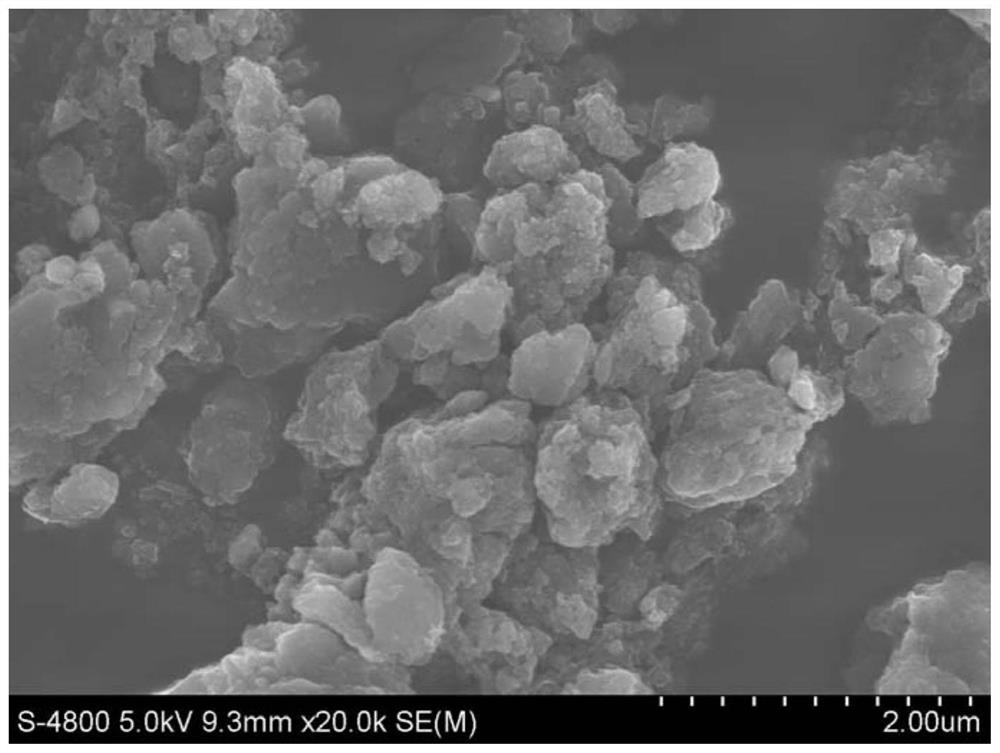

[0029]According to a specific embodiment of the present invention, the edge-modified graphene is prepared by a method comprising the following steps:

[0030] Step S1, adding purified or unpurified graphite powder into a high-pressure grinding disc kettle;

[0031] Step S2, passing carbon dioxide into a high-pressure grinding disc kettle and making it in a supercritical state to form a material comprising graphite powder and supercritical carbon dioxide;

[0032] Step S3, grinding the material containing graphite powder and supercritical carbon dioxide.

[0033] According to some embodiments of the present invention, the graphite powder is selected from flake graphite powder and expanded graphite powder, preferably, the particle size of the graphite powder is 10-80 mesh, preferably 20-60 mesh.

[0034] According to some embodiments of the present invention, before grinding, the graphite powder is preferably pre-purified, such as ultrasonic cleaning and / or chemical treatment, ...

Embodiment approach

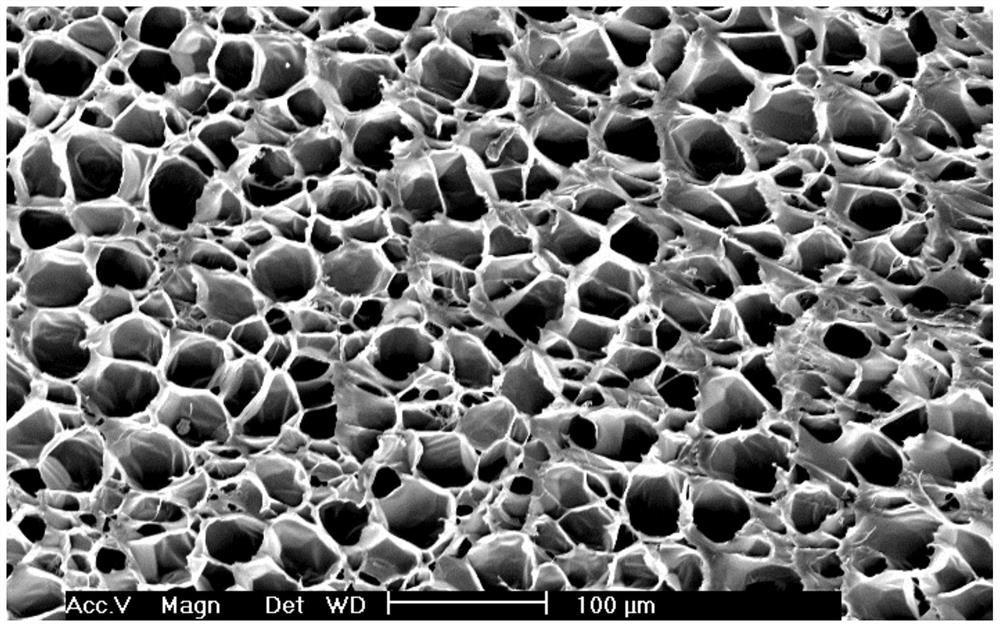

[0056] According to one embodiment of the present invention, the polyolefin is polypropylene, and the grafted polyolefin is grafted polypropylene; preferably, the polypropylene is a random copolymerized polypropylene, which is obtained at a temperature of 190°C and 2.16 The melt index under kg load is 5-9g / 10min, and the molecular weight distribution is M w / M n for 5-20.

[0057] Specifically, the random copolymerized polypropylene is selected from ethylene-propylene random copolymerized polypropylene, propylene-butylene random copolymerized polypropylene, and ethylene-propylene-butylene random copolymerized polypropylene. That is, the comonomer used in the random copolymerized polypropylene is one or both of ethylene and butene. All of the random copolymer polypropylenes mentioned above are commercially available.

[0058] According to another embodiment of the present invention, the polyolefin is polyethylene, and the grafted polyolefin is grafted polyethylene.

[0059]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com