Preparation method of matching layer for relaxor ferroelectric single crystal ultrasonic transducer

A technology of relaxor ferroelectric single crystal and ultrasonic transducer, which is applied in the fields of industry and medicine, can solve the problems affecting the compact performance and the inability to realize mass production, and achieve high yield, convenient processing, and uniform distribution of material impedance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

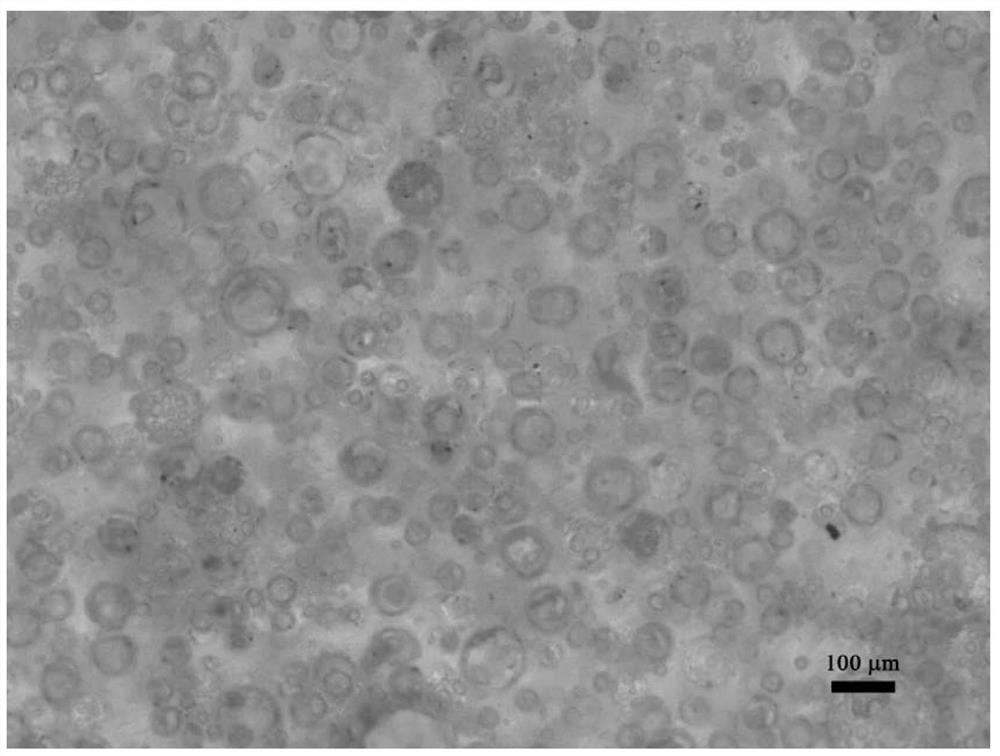

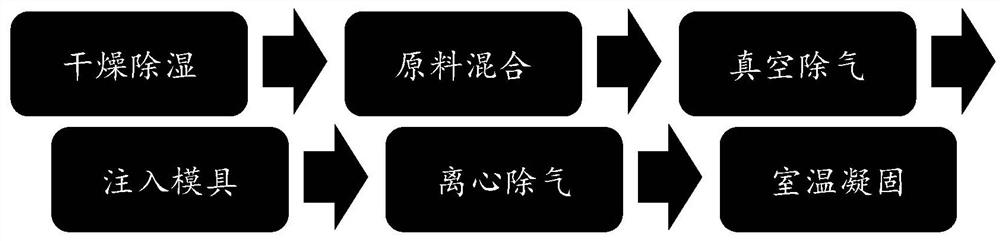

[0038] The preparation method of this example 1 is: first put the HN20 hollow glass (silicon dioxide and aluminum oxide) powder produced by Yixiang New Material Co., Ltd. Liquid epoxy resin and 18-20wt% hollow glass powder as raw materials, plus 18-20wt% curing agent (98.5wt% diethylenetriamine and 1.5wt% butyl glycidyl ether), fully mixed for 3 ~ 10 minutes to prepare the slurry; put the slurry in a vacuum drying oven at room temperature, and perform vacuum degassing for 10 minutes at 25°C and a pressure of -0.1MPa, and cycle 3 times. Then inject the processed slurry into the mold, put it into a centrifuge for centrifugal degassing (500 rpm, 5 minutes, cycle 2 times), solidify the centrifuged slurry at room temperature (25°C) for 36h, and degas After molding, it is selected and thinned according to the required impedance, and the matching layer of the required relaxation ferroelectric single crystal ultrasonic transducer is obtained. Under the test conditions of room tempera...

Embodiment 2

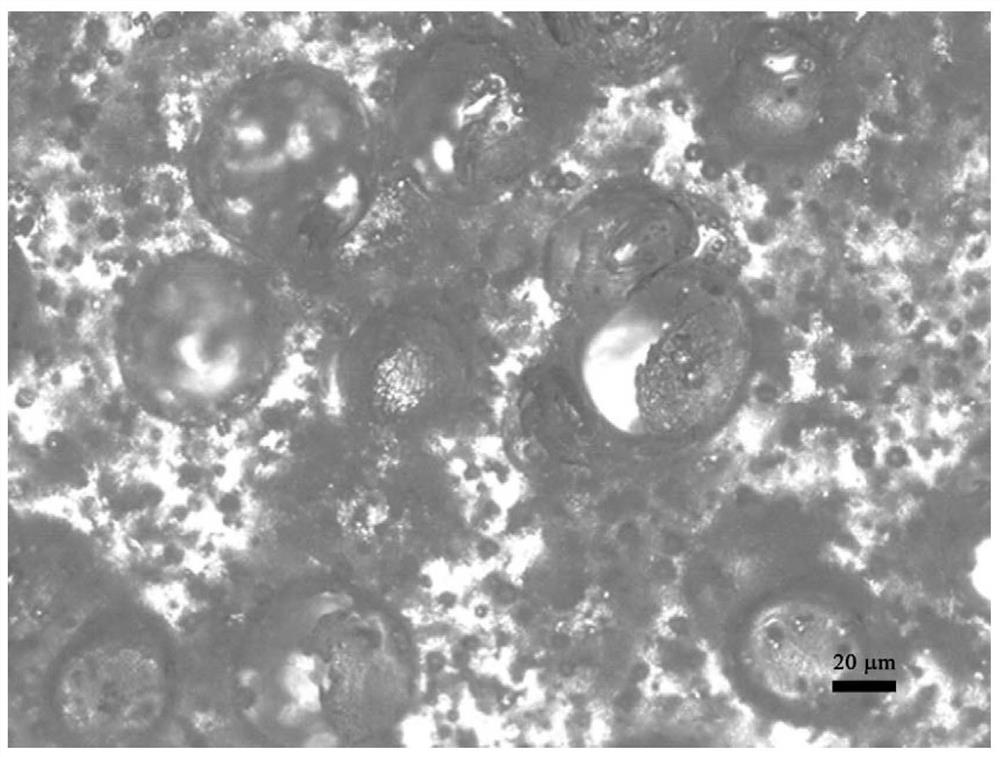

[0040]The preparation method of Example 2 is as follows: first put the zirconia powder into an oven at 50°C to dry for more than 6 hours, and use 15-17wt% bisphenol A liquid epoxy resin and 77-80wt% zirconia powder as raw materials , add 5-6wt% curing agent (diethylenetriamine), and mix thoroughly for 3-10 minutes to make a slurry; put the slurry in a vacuum oven at room temperature, at 25°C and a pressure of -0.1MPa, carry out 10min vacuum degassing, and cycle 4 times. Then inject the treated slurry into the mold, put it into a centrifuge for centrifugal degassing (500 rpm, 5 minutes, cycle 2 times), and solidify the centrifuged slurry at room temperature (25°C) for 36 hours. After demolding The matching layer of the relaxation ferroelectric single crystal ultrasonic transducer is obtained by selecting and thinning according to the required impedance. Under the test conditions of room temperature (25° C.) and a frequency of 5 MHz, the acoustic impedance of the matching layer...

Embodiment 3

[0042] The preparation method of Example 3 is as follows: first put the alumina powder into an oven at 50° C. to dry for more than 6 hours, use 56 to 66 wt % of bisphenol A liquid epoxy resin and 17 to 30 wt % of alumina powder as raw materials, and then Add 14-17wt% curing agent (modified polyether amine), and mix thoroughly for 3-10 minutes to make a slurry; put the slurry in a vacuum oven at room temperature, at 25°C and a pressure of -0.1MPa, for 10 minutes The vacuum degassing, and the number of cycles 5 times. Then inject the treated slurry into the mold, put it into a centrifuge for centrifugal degassing (500 rpm, 5 minutes, cycle 3 times), and solidify the centrifuged slurry at room temperature (25°C) for 36 hours. After demolding The matching layer of the relaxation ferroelectric single crystal ultrasonic transducer is obtained by selecting and thinning according to the required impedance. Under the test conditions of room temperature (25° C.) and a frequency of 5 MH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com