Pretreatment process and equipment for squeezed crude oil

A pretreatment and crude oil technology, which is applied in the direction of fat oil/fat refining, separation method, filtration separation, etc., can solve the problems of insignificant slag discharge effect and slow slag discharge efficiency, and achieve the effect of good sealing and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

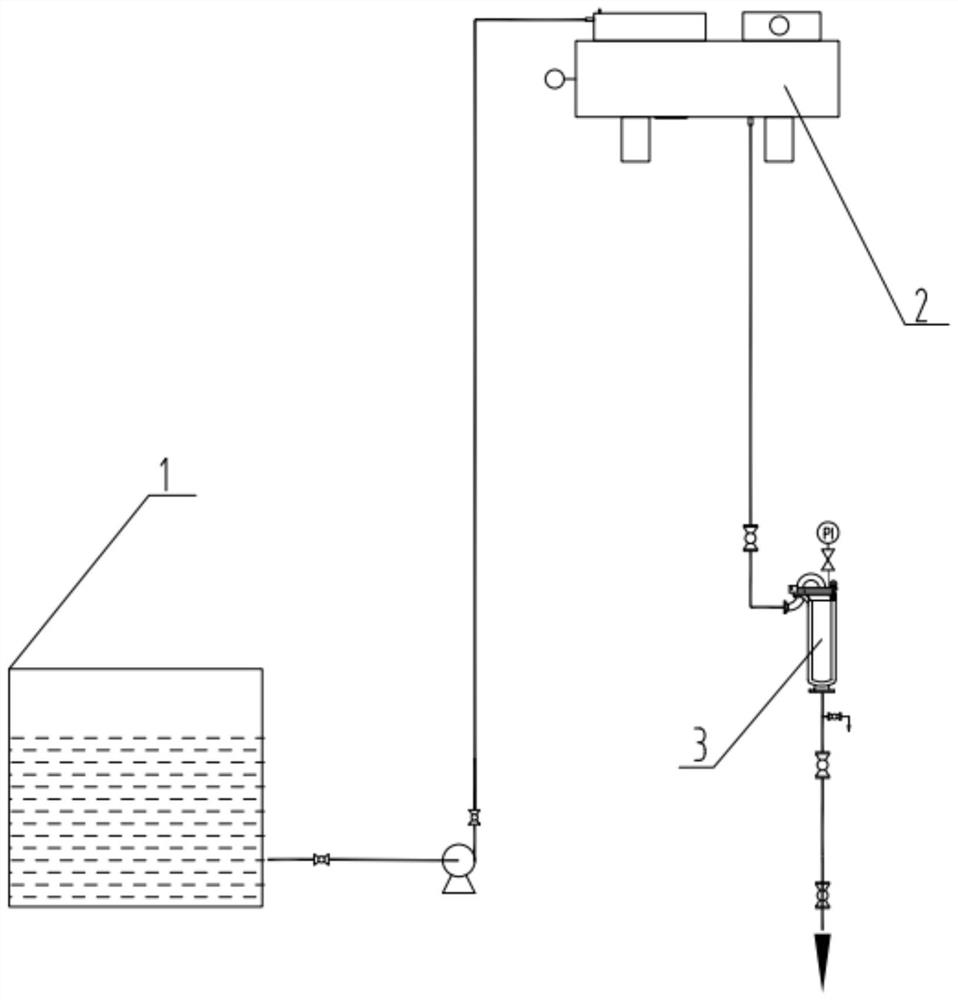

[0026] A kind of pretreatment equipment for pressed crude oil, including an impurity removal device, the impurity removal device includes a decanter centrifuge 2 and a cloth bag filter 3, one end of the decanter centrifuge 2 is connected to a clarified oil tank 1 storing pressed crude oil through a pipeline, The other end of the decanter centrifuge 2 is connected with the bag filter 3 through a pipeline.

[0027] In the present embodiment, the crude oil pretreatment process of pressing is:

[0028] (1) Rapeseed impurity removal: The rapeseed uses a dust collector to remove floating dust, and then the dedusted rapeseed is processed through a vibrating screen to remove large particles of impurities, and then rolled by a flaking machine to a thickness of 0.8mm and a water content of 8% of the cake.

[0029] (2) Pressing: The cake after removing impurities in step (1) is put into a steamer and fried at 115°C for steaming and frying to form wet rapeseed meal, which is sent to an o...

Embodiment 2

[0032] (1) Rapeseed impurity removal: the rapeseed uses a dust collector to remove floating dust, and then the dedusted rapeseed is processed through a vibrating screen to remove large particles of impurities, and then rolled by a flaking machine to a thickness of 0.6mm and a water content of It is 1% thick material cake.

[0033] (2) Pressing: The thick cake after removing impurities in step (1) is put into a steamer and fried at 110°C for steaming and frying to form wet rapeseed meal, which is sent to an oil press to control the pressing The temperature of the oil machine is 115°C, the pressure is 35Mpa, and pressing is carried out to obtain pressed crude oil.

[0034] (3) Secondary impurity removal: the pressed crude oil is input into the clear oil tank and left to stand for 8 hours, then pumped into a decanter centrifuge, and centrifuged at a speed of 2800rpm to remove small impurities and colloids in the pressed crude oil, and then passed through into the cloth bag filte...

Embodiment 3

[0036] (1) Rapeseed impurity removal: the rapeseed uses a dust collector to remove floating dust, and then the dedusted rapeseed is processed through a vibrating screen to remove large particles of impurities, and then rolled by a flaking machine to a thickness of 1.0mm and a water content of It is 4% thick material cake.

[0037] (2) Pressing: The thick cake after removing impurities in step (1) is put into a steamer and fried at 120°C for steaming and frying to form wet rapeseed meal. The temperature of the oil machine is 95°C, the pressure is 45Mpa, and pressing is carried out to obtain pressed crude oil.

[0038] (3) Secondary impurity removal: the pressed crude oil is input into the oil tank and left to stand for 10 hours, then pumped into a decanter centrifuge, and centrifuged at a speed of 3600rpm to remove small impurities and colloids in the pressed crude oil, and then passed through into the cloth bag filter to remove tiny impurities in the pressed crude oil. The fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com