High-hardness alloy aluminum and production process thereof

A kind of alloy aluminum, high hardness technology, applied in the direction of metal material coating process, other household appliances, ceramic products, etc., can solve the problems of poor antibacterial performance, insufficient mechanical strength, etc., to improve sterilization performance, enhance sterilization performance, and ensure quality effect with quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

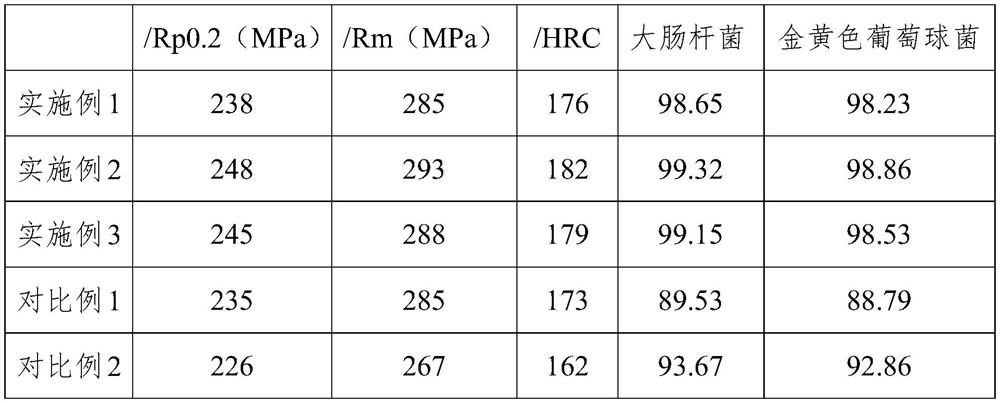

Embodiment 1

[0033] A high-hardness alloy aluminum, high-hardness alloy aluminum includes an alloy aluminum profile matrix and a wear-resistant layer on the surface of which a functional enhancer is melted by laser melting; and the alloy aluminum profile matrix is composed of the following components by weight percentage: Fe : 0.3%, Si: 0.3%, Cu: 0.002%, Mn: 1.0%, Mg: 0.56%, Zn: 4.5%, Ti: 0.06%, Ag: 0.05%, Cr: 0.05%, V: 0.04%, Zr : 0.05%, Ni: 0.25%, RE: 0.06%, and the rest is Al.

[0034] RE is prepared by mixing yttrium, lanthanum, and praseodymium in a mass ratio of 1:0.3:0.2.

[0035] The preparation method of the functional enhancer used in the wear-resistant layer comprises the following steps:

[0036] Ⅰ. Immerse the inorganic porous micropowder in an appropriate amount of N, N-dimethylformamide according to the solid-to-liquid ratio of 0.08g / mL, and dry it after ultrasonic shock treatment for 30 minutes; dry and store the inorganic porous micropowder after drying ,spare;

[0037]...

Embodiment 2

[0052] The production process of described high-hardness alloyed aluminum is roughly similar to the technical solution provided in Example 1, and the main differences between the two are as follows:

[0053] The alloy aluminum profile matrix is composed of the following components by weight: Fe: 0.4%, Si: 0.35%, Cu: 0.006%, Mn: 1.2%, Mg: 0.78%, Zn: 5.2%, Ti: 0.1%, Ag: 0.22%, Cr: 0.07%, V: 0.06%, Zr: 0.08%, Ni: 0.4%, RE: 1%, and the rest is Al.

[0054] RE is prepared by mixing yttrium, lanthanum, and praseodymium at a mass ratio of 1:0.4:0.3.

[0055] The preparation method of the functional enhancer used in the wear-resistant layer comprises the following steps:

[0056] Ⅰ. Immerse the inorganic porous micropowder in an appropriate amount of N,N-dimethylformamide according to the solid-to-liquid ratio of 0.12g / mL, and dry it after ultrasonic shock treatment for 40min; dry and store the inorganic porous micropowder after drying ,spare;

[0057] Ⅱ. Put the dried inorganic ...

Embodiment 3

[0067] The production process of described high-hardness alloyed aluminum is roughly similar to the technical solution provided in Example 1, and the main differences between the two are as follows:

[0068] The alloy aluminum profile matrix is composed of the following components by weight: Fe: 0.5%, Si: 0.4%, Cu: 0.01%, Mn: 1.5%, Mg: 0.95%, Zn: 6.0%, Ti: 0.13%, Ag: 0.32%, Cr: 0.09%, V: 0.08%, Zr: 0.1%, Ni: 0.5%, RE: 1.2%, and the rest is Al.

[0069] RE is prepared by mixing yttrium, lanthanum and praseodymium in a mass ratio of 1:0.3-0.5:0.2-0.35.

[0070] The preparation method of the functional enhancer used in the wear-resistant layer comprises the following steps:

[0071] Ⅰ. Immerse the inorganic porous micropowder in an appropriate amount of N,N-dimethylformamide according to the solid-to-liquid ratio of 0.15g / mL, and dry it after ultrasonic shock treatment for 50 minutes; dry and store the inorganic porous micropowder after drying ,spare;

[0072] Ⅱ. Put the dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com