Rapid determination method for copper foil electroplating solution

A rapid measurement and electroplating solution technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of one-by-one analysis, long analysis time, cumbersome operation, etc., and achieve high detection efficiency, accurate test results, and small deviation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] Embodiment, a kind of rapid assay method of copper foil electroplating solution,

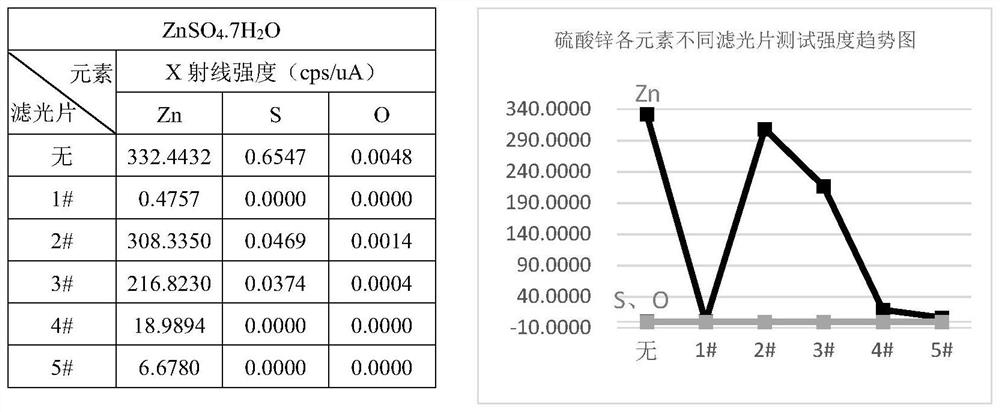

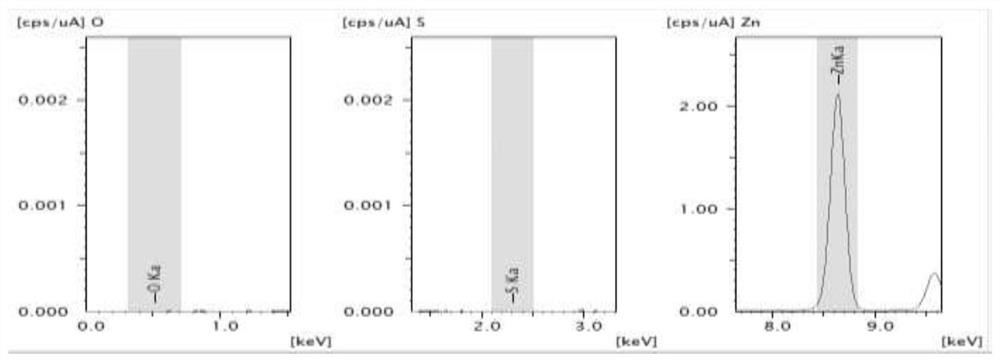

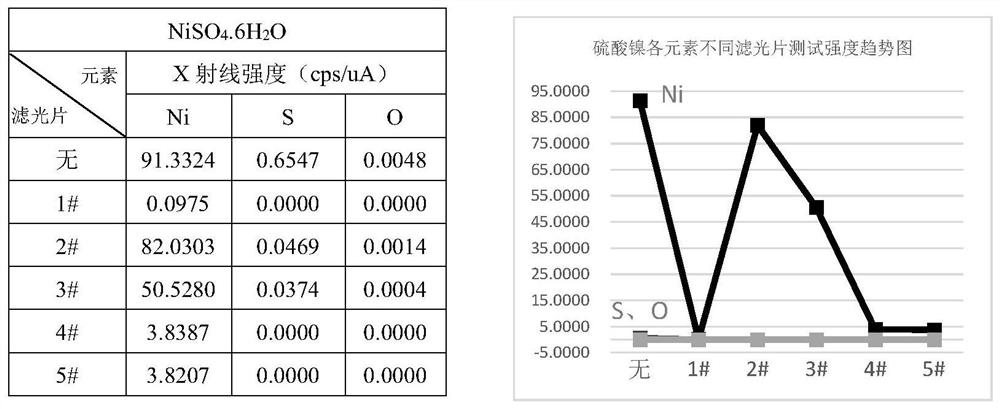

[0058] S1. Determine the best experimental conditions: analyze the spectrum structure of a single reagent to confirm the best test conditions, and then verify and analyze the spectrum structure of the mixed solution;

[0059] S2. Establish a standard working curve for testing: prepare the standard reagents required for the standard curve, test the X-ray intensity of the standard solution, and establish a standard curve for testing;

[0060] S3. Verification of the accuracy of the measurement: verify the error of the test result of preparing a known concentration solution, verify the error of multiple tests of the same unknown concentration plating solution on the production site, and obtain the measurement error according to the verification test result;

[0061] S4. Put the electrolyte solution to be tested into the device for measurement, and compare it with the test standard working curv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com