Brushless direct current motor sensorless control method based on sliding mode observer

A sliding mode observer, brushed DC motor technology, applied in the direction of AC motor control, motor control, motor generator control, etc., can solve the problems of difficulty in obtaining the back EMF of the brushless DC motor, increase the control complexity, etc., to reduce jitter Vibration phenomenon, avoid installation, enhance the effect of robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with the accompanying drawings.

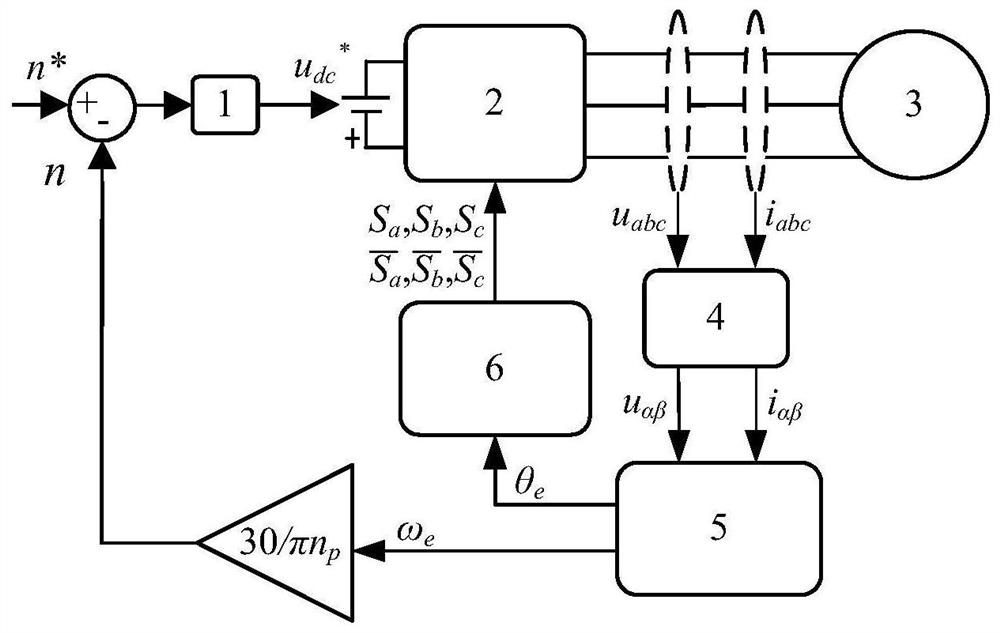

[0037] A position sensorless control method for brushless DC motors based on a sliding mode observer is based on a system such as figure 1 As shown, it includes a speed outer loop PI controller 1, an inverter and a commutation drive circuit 2, a brushless DC motor 3, a coordinate transformation module 4, a sliding mode observer 5, and a commutation table 6.

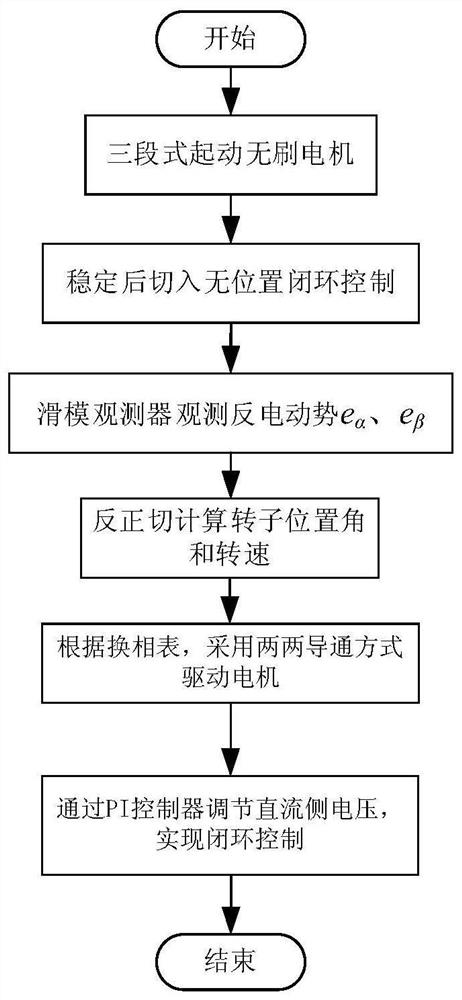

[0038] Such as figure 2 As shown, the method includes the following steps:

[0039] Step 1: Start the brushless DC motor through the three-stage starting technology, and switch to the closed-loop control of the brushless DC motor without position sensor based on the sliding mode observer after the system is stable. Specifically, the three-stage starting technology includes three stages: rotor pre-positioning, acceleration, and operating state switching;

[0040] Step 2: Use the sliding mode observer to observe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com