Preparation process of ceramic-based circuit board and product

A preparation process and circuit board technology, which is applied in the direction of printed circuit manufacturing, printed circuit, and printed circuit precursor manufacturing, can solve the problems of limited wire width-to-depth ratio, low thermal conductivity of finished products, and expensive preparation costs, etc., to achieve low stress, The effects of compact grains and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] A preparation process for a ceramic-based circuit board, comprising the following steps:

[0024] Vacuum plasma magnetron sputtering Cu on the surface of copper sheet 2 O, forming a layer of Cu 2 O film;

[0025] The ceramic substrate is placed on the copper sheet, and the stepwise intermittent heating method is used for bonding to obtain the circuit substrate;

[0026] Then, the stepwise intermittent cooling method is used to cool the circuit substrate;

[0027] The copper surface of the circuit substrate is recrystallized by high and low temperature alternating method, and the ceramic base circuit board is obtained by cooling.

[0028] The present invention adopts a stepwise intermittent heating method and a stepwise intermittent cooling method for continuous dynamic bonding, which can maximize the release of the stress when the copper sheet is combined with the ceramic, thereby eliminating the stress caused by the different expansion coefficients of the two materi...

Embodiment 1

[0039] A ceramic-based circuit board, the preparation process of which is:

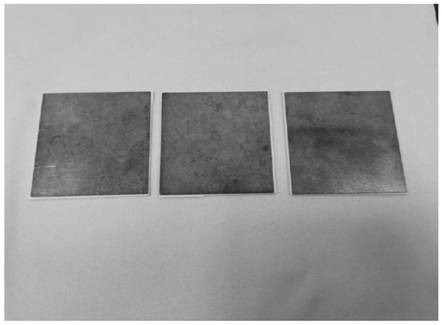

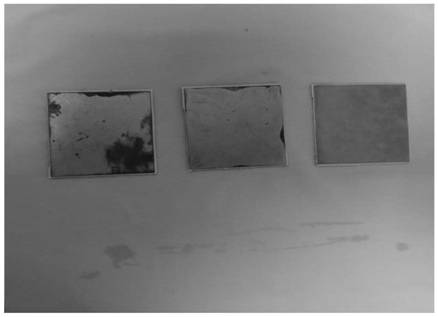

[0040] The OFC oxygen-free copper sheet with a size of 180mm×218mm and a thickness of 100μm was firstly cleaned with pure water and then dried, and then the two sides of the copper sheet were plated with Cu by vacuum plasma magnetron sputtering 2 O, so that 1 μm dense Cu is formed on the surface 2 O film;

[0041] The size is 184mm×222mm, the thickness is 1000μm, and the Al content is 99%. 2 o 3The ceramic sheet is ultrasonically cleaned with pure water and then dried. The ceramic sheet and the copper sheet are stacked and placed in a transmission-type mesh belt atmosphere tunnel furnace, and the temperature is raised by a step-by-step intermittent heating method, specifically: at 30°C / min Raise the temperature from room temperature to 450°C at a speed of 450°C, and keep it for 3 to 5 minutes; raise the temperature at a speed of 40°C / min to 800°C, and keep it for 4 minutes; Raise the temperature t...

Embodiment 2

[0043] A ceramic-based circuit board, the preparation process of which is:

[0044] Use the OFC oxygen-free copper sheet with a size of 180mm×218mm and a thickness of 450μm, first clean it with pure water ultrasonically, then dry it, and then conduct vacuum plasma magnetron sputtering Cu plating on both sides of the copper sheet 2 O, to form a 3 μm dense Cu on its surface 2 O film;

[0045] The size is 184mm×222mm, the thickness is 1520μm, and the Al content is 80%. 2 o 3 The ceramic sheet is ultrasonically cleaned with pure water and then dried. The ceramic sheet and the copper sheet are stacked and placed in a transmission mesh belt atmosphere tunnel furnace, and the temperature is raised by a stepwise intermittent heating method, specifically: at 28°C / min Raise the temperature from room temperature to 440°C at a speed of 440°C, and keep it for 3-5 minutes; raise the temperature at a speed of 42°C / min to 810°C, and keep it for 5 minutes; raise the temperature at a speed o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com