Light emitting diode, light emitting diode package, and plant lighting device

A technology of light-emitting diodes and semiconductors, applied in the fields of botanical equipment and methods, semiconductor devices, energy-saving measures, etc., can solve the problems of consumption or absorption, and light less than the critical angle may be emitted during one or more oscillations. , to achieve the effect of improving luminous brightness and improving light extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

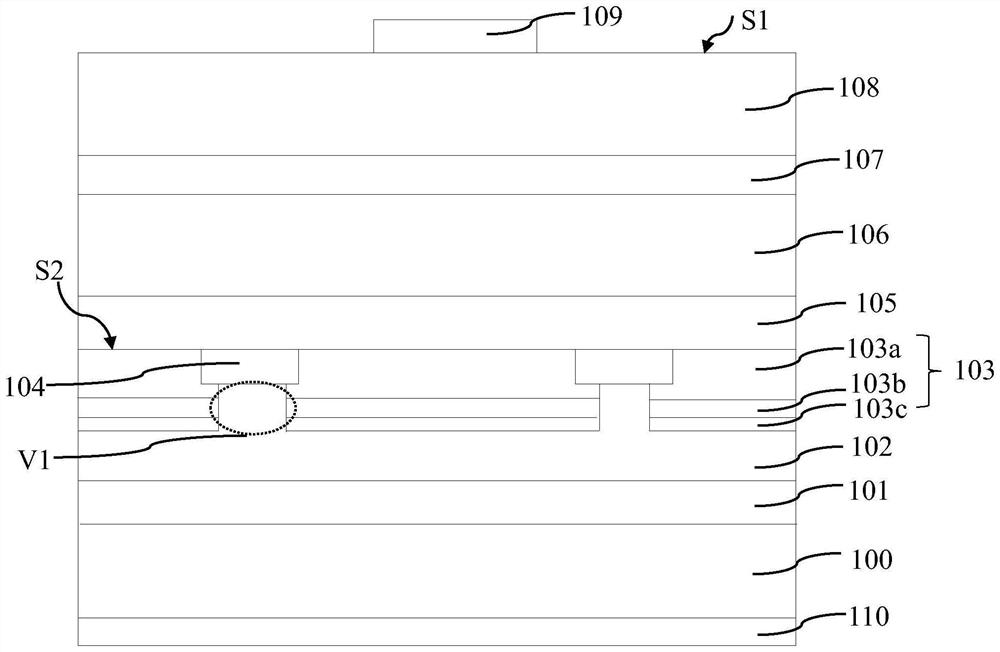

[0029] This embodiment provides the following light emitting diode, such as figure 1 The cross-sectional schematic diagram shown, which includes the following stacked layers: 100: substrate; 101: metal bonding layer; 102: reflective layer; 103: light-transmitting dielectric layer structure; 103a: first sublayer; 103b: second sublayer ; 103c: third sublayer; 104: ohmic contact layer; 105: current spreading layer; 106: second conductivity type semiconductor layer; 107: active layer; 108: first conductivity type semiconductor layer; 109: first electrode; 110: second electrode.

[0030] In this embodiment, the light-emitting diode has a semiconductor epitaxial stack, which is obtained by MOCVD or other growth methods, and is a semiconductor material that can provide conventional radiation such as ultraviolet, blue, green, yellow, red, and infrared light. Specifically, it can be 200~950nm materials, such as common nitrides, such as gallium nitride-based semiconductor epitaxial sta...

Embodiment 2

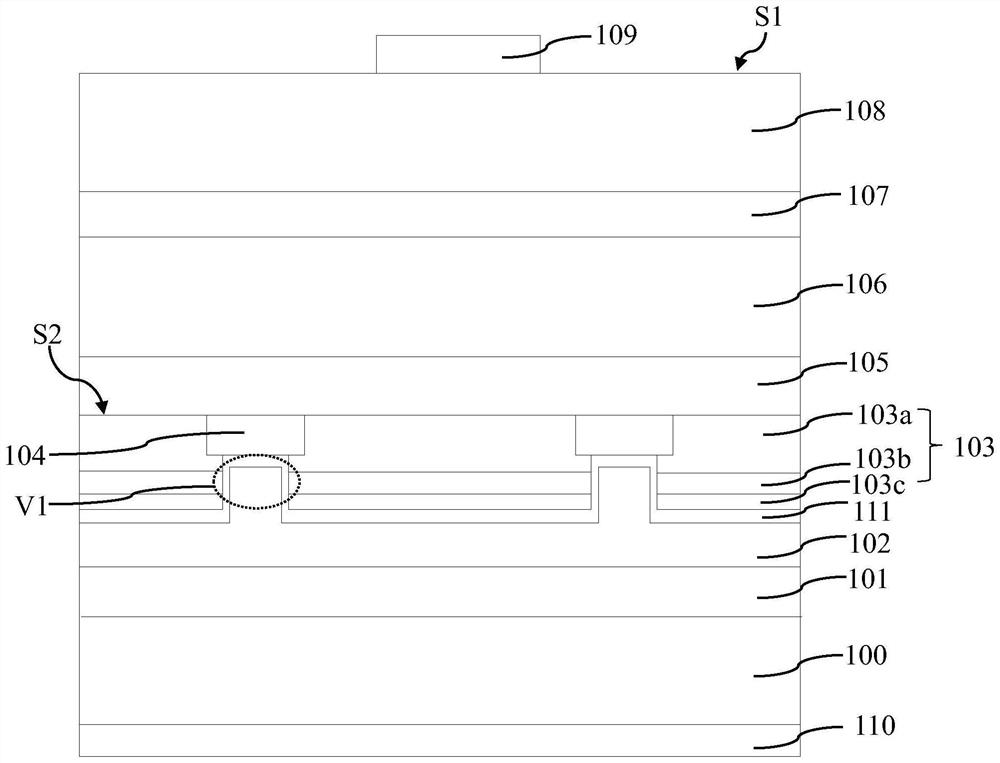

[0046] and Example 1 figure 1 Compared with the light emitting diode shown, in order to improve the adhesion between the semiconductor epitaxial stack and the reflective layer 102, as figure 2 As shown, the light emitting diode also includes an adhesive layer 111, the adhesive layer 111 is formed on the side of the light-transmitting dielectric layer structure 103 away from the semiconductor epitaxial stack, the adhesion layer 111 is a light-transmitting conductive material, The light-transmitting conductive material is specifically IZO or ITO, etc., and is more preferably a material with good adhesion between the light-transmitting dielectric layer structure 103 and the reflective layer 102, such as gold or silver.

[0047] The thickness of the adhesion layer is greater than 2nm, preferably the thickness of the adhesion layer is more than 5nm, so as to achieve a better adhesion effect. In some optional embodiments, the adhesive layer is a continuous film layer, and in some ...

Embodiment 3

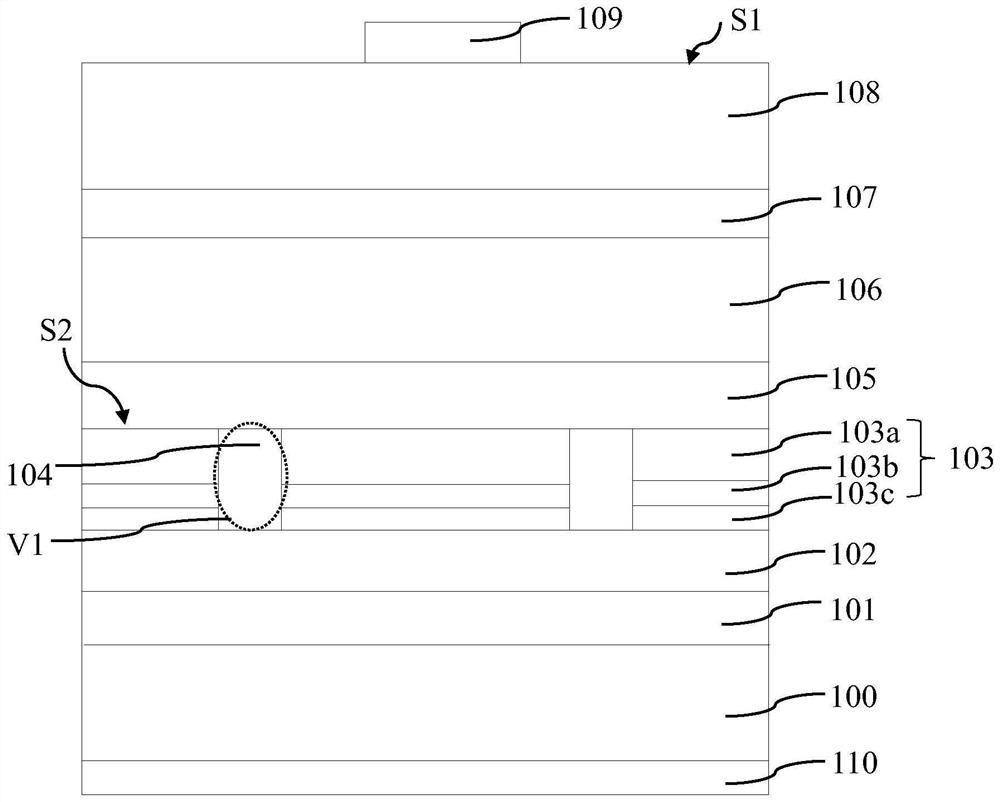

[0049] image 3 It is a schematic structural diagram of a light emitting diode in another embodiment of the present invention. Such as image 3 As shown, the light-transmitting dielectric layer structure 103 has a through hole V1, the ohmic contact layer 104 is disposed in at least one through-hole V1 of the light-transmitting dielectric layer structure 103, and the ohmic contact layer 104 passes through the through-hole V1. The hole V1 forms an ohmic contact with the current spreading layer 105, and the current is evenly transmitted from the metal bonding layer 101, the through hole V1 connecting the reflective layer 102 and the ohmic contact layer 104 to the semiconductor epitaxial stack, so the ohmic contact layer 104 covers at least a plurality of The area of the via hole V1 does not completely cover one side of the contact current spreading layer 105 . The ohmic contact layer 104 uses a conductive metal or a transparent conductive layer. The conductive metal is prefe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com