Preparation method of polyhedral oligomeric silsesquioxane hybridized whole and product of polyhedral oligomeric silsesquioxane hybridized whole

A polyhedron and multifold technology, applied in the field of hybrid materials, can solve the problems of initiator residue, cumbersome process, time and manpower consumption, etc., and achieve the effects of property expansion, production efficiency improvement and production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

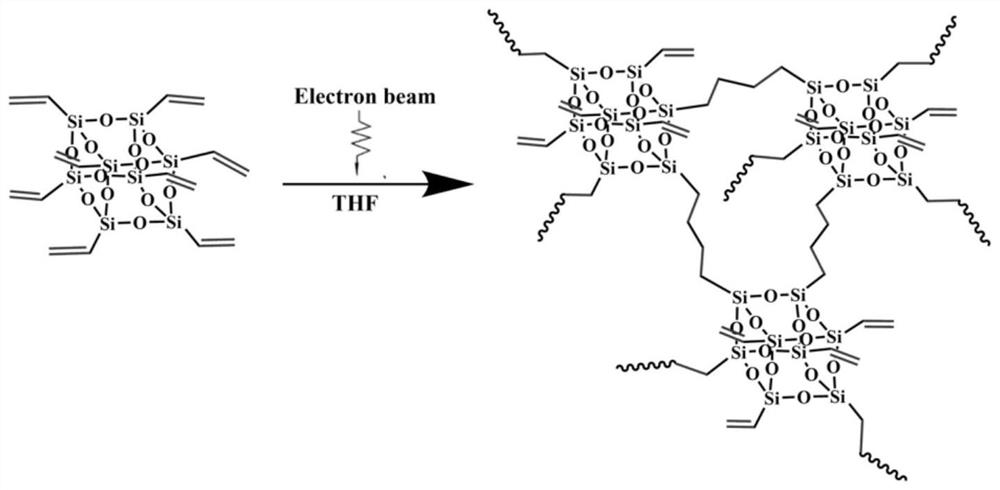

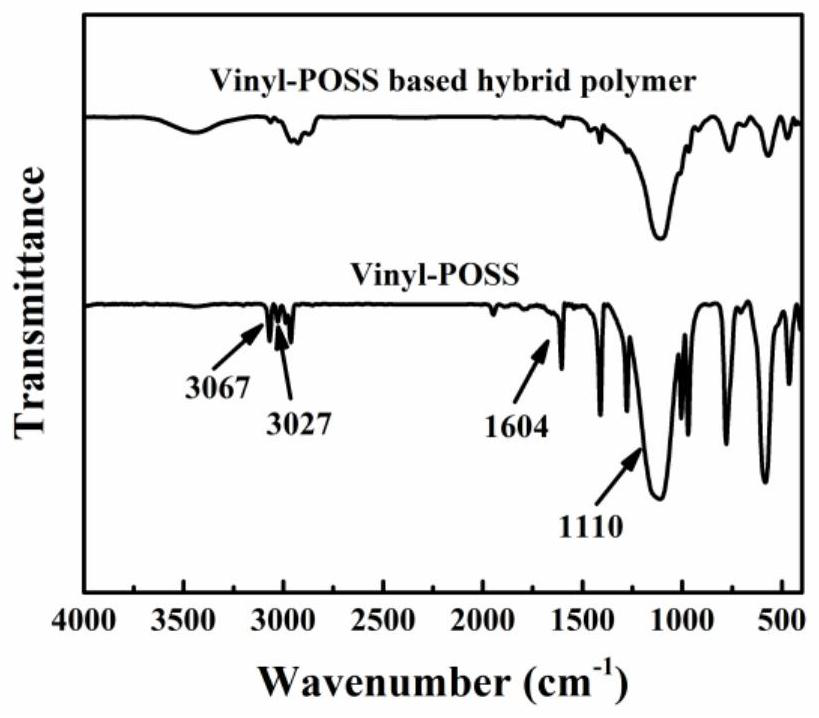

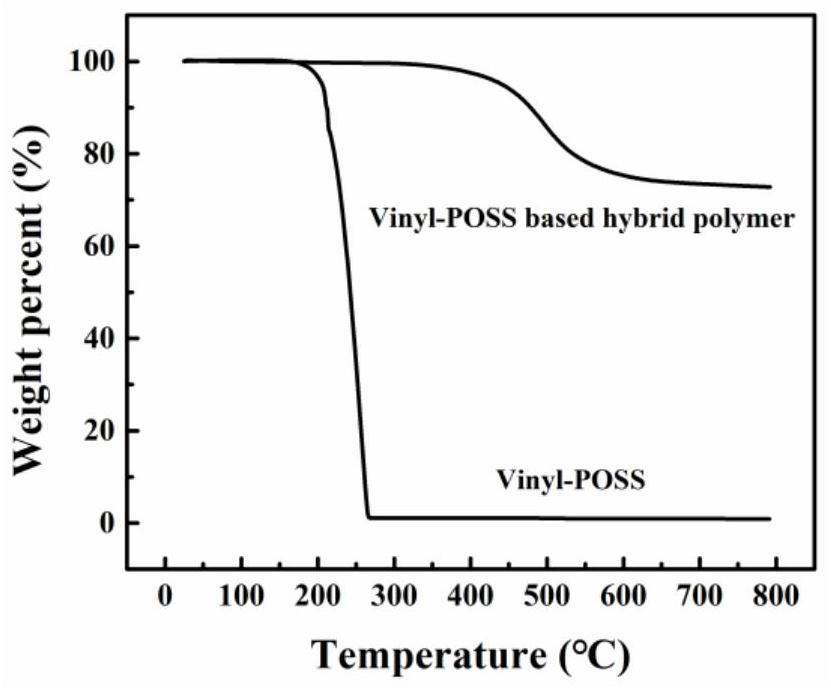

[0024] see figure 1 , In this embodiment, a method for preparing a polyhedral oligomeric silsesquioxane hybrid monolith is provided, and the specific steps are as follows:

[0025] Step 1: Prepare Vinyl-POSS monomer; add the mixture of concentrated hydrochloric acid and deionized water to the acetone solution of vinyltrimethoxysilane, stir and reflux at 40°C for 48h, wash the white powder with ethanol, and dichloromethane Vinyl-POSS monomer can be obtained after recrystallization in a mixed solvent of acetone.

[0026] Step 2: Prepare Vinyl-POSS solution, inject Vinyl-POSS monomer and THF solution into a polyethylene bag and seal it after continuously passing inert gas to remove oxygen. The molar concentration of Vinyl-POSS monomer is 0.01-1.0mol L- 1.

[0027] Step 3: Under room temperature, use an electron accelerator beam device to perform radiation polymerization / crosslinking reaction on the sample obtained in step 2 to obtain a colorless transparent solid. The absorbed ...

Embodiment 2

[0031] In this embodiment, a method for preparing a polyhedral oligomeric silsesquioxane hybrid monolith, the specific steps are as follows:

[0032] Step 1: Dissolve 13.3g of vinyltrimethoxysilane, 90mmol, in 135mL of acetone solvent, drop a mixed solution of 22.5mL of concentrated hydrochloric acid and 25.9mL of deionized water into acetone, stir and reflux at 40°C for 48h;

[0033] When a white solid precipitates on the wall of the flask and the reaction solution turns brown, transfer the solid and the solution in the flask to a beaker, filter with suction, wash the precipitate with ethanol and dry it in vacuum at 60°C for 24 hours to obtain a white powder;

[0034] The crude product was finally recrystallized with a 1:3 mixed solvent of dichloromethane and acetone to obtain 2.37 g of white powder, namely Vinyl-POSS monomer, with a yield of 33.3%.

[0035] Step 2: Add a certain quality of Vinyl-POSS monomer and a certain volume of THF into a polyethylene plastic bag, and se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com