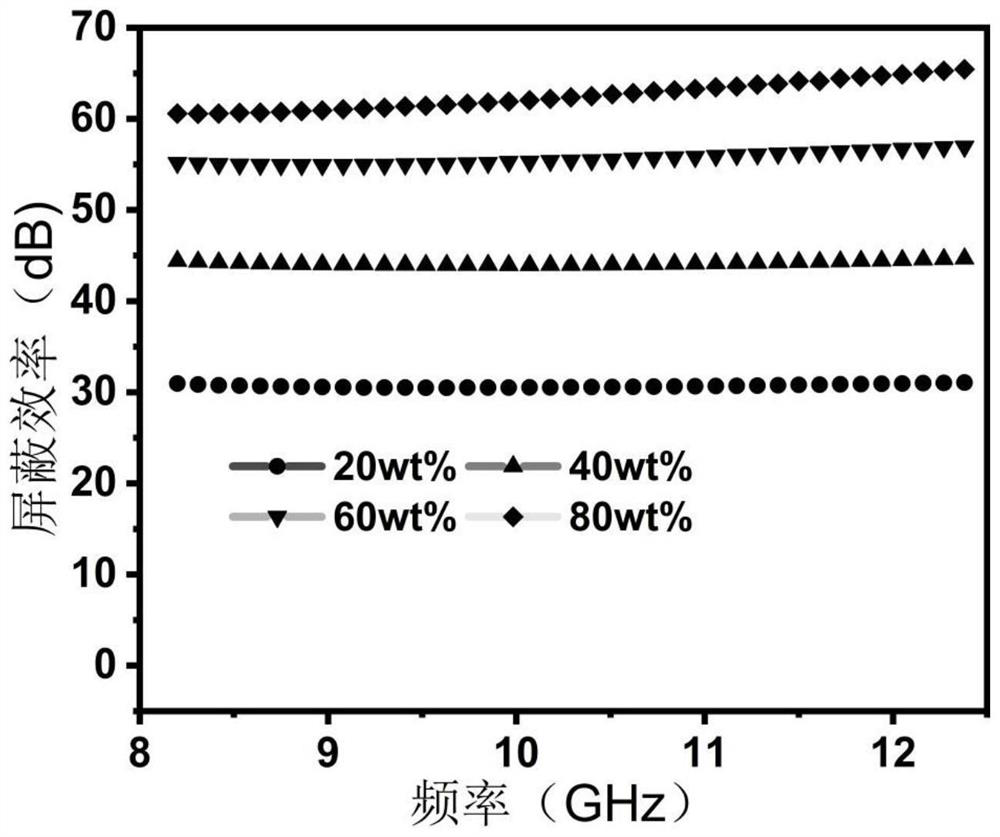

ANFs/MXene composite electromagnetic shielding aerogel and preparation method thereof

A composite electromagnetic and shielding gas technology, applied in the fields of magnetic field/electric field shielding, electrical components, etc., can solve the problems of inapplicability and easy collapse of aerogels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a preparation method of ANFs / MXene composite electromagnetic shielding airgel, comprising the following steps:

[0031] (1) mixing polar organic solvents, Kevlar 29 fibers and hydroxides of alkali metals to obtain ANFs colloids; the Kevlar 29 fibers are dried before use; the mixing conditions are vacuum;

[0032] (2) adding water dropwise to the ANFs colloid obtained in step (1), and then performing suction filtration and washing successively to obtain the ANFs precursor film;

[0033] (3) Add the MXene dispersion liquid dropwise on the surface of the ANFs precursor film obtained in step (2), and then pulverize after standing to obtain a mixed gel precursor;

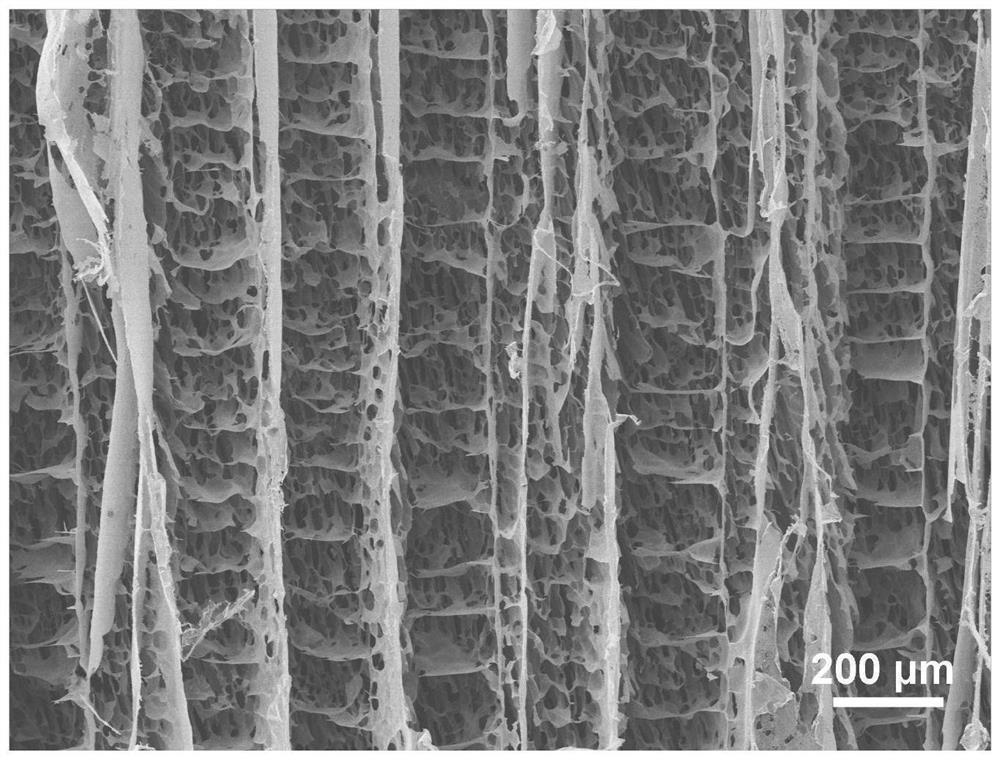

[0034] (4) The gel precursor obtained in step (3) was subjected to directional freezing, and then freeze-dried to obtain ANFs / MXene composite electromagnetic shielding airgel.

[0035] The invention mixes polar organic solvent, Kevlar 29 fiber and alkali metal hydroxide to obtain ANFs collo...

Embodiment 1

[0061] (1) Preparation of ANFs: Kevlar 29 chopped fibers are pretreated, and Kevlar 29 chopped fibers are dried in a vacuum oven at 120°C for 12 hours to completely remove moisture;

[0062] Add 1000mL dimethyl sulfoxide, 2g Kevlar29 chopped fiber and 3g potassium hydroxide to the dry flask in turn, pump the vacuum 3 times to remove the air, ensure an anhydrous environment, stir for 7 days, and obtain a uniformly dispersed 2mg / ml ANFs colloid.

[0063] (2) Preparation of MXene dispersion: take 400 mesh 1g of Ti 3 AlC 2 Put it into a polytetrafluoroethylene reactor with a stirring rod, slowly add a mixture of 1g of LiF and 20ml of HCl with a concentration of 9mol / L to the reactor, and after the addition is completed within 15min, at a stirring rate of 550r / min, React for 24 hours at a temperature of 35°C; wash the product with deionized water until pH>6, then centrifuge, add the lower layer product to the gas washing bottle, add 60ml of deionized water at the same time, pass i...

Embodiment 2

[0071] (1) Preparation of ANFs: Kevlar 29 chopped fibers are pretreated, and Kevlar 29 chopped fibers are dried in a vacuum oven at 120°C for 12 hours to completely remove moisture;

[0072] Add 800mL dimethyl sulfoxide, 2g of Kevlar 29 chopped fiber and 3g of potassium hydroxide to a completely dry flask in turn, pump vacuum 3 times to remove air, ensure anhydrous environment, stir for 7 days, and obtain evenly dispersed 2.5 mg / ml ANFs colloid.

[0073] (2) Preparation of MXene dispersion: take 400 mesh 1g of Ti 3 AlC 2 Put it into a polytetrafluoroethylene reactor with a stirring rod, slowly add a mixture of 1g of LiF and 20ml of HCl with a concentration of 9mol / L to the reactor, and after the addition is completed within 15min, at a stirring rate of 550r / min, React for 24 hours at a temperature of 35°C; wash the product with deionized water until pH>6, then centrifuge, add the lower layer product to the gas washing bottle, add 60ml of deionized water at the same time, pas...

PUM

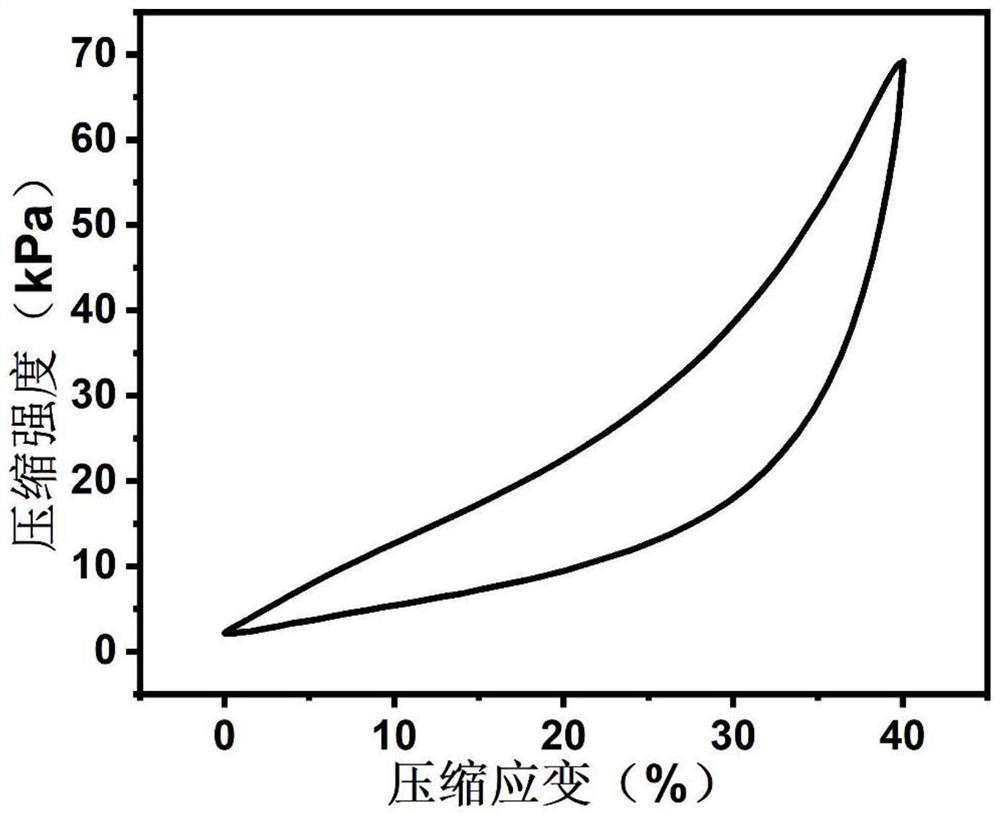

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com