CCM for fuel cell and preparation method thereof

A fuel cell and slurry technology, applied in the direction of fuel cells, battery electrodes, circuits, etc., can solve the problems of degradation and loss of precious metal catalysts, reduce the effective catalytic area, and reduce the performance of electrodes, so as to achieve good resistance to degradation and loss, durability, drainage, etc. Good effect, the effect of reducing impedance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

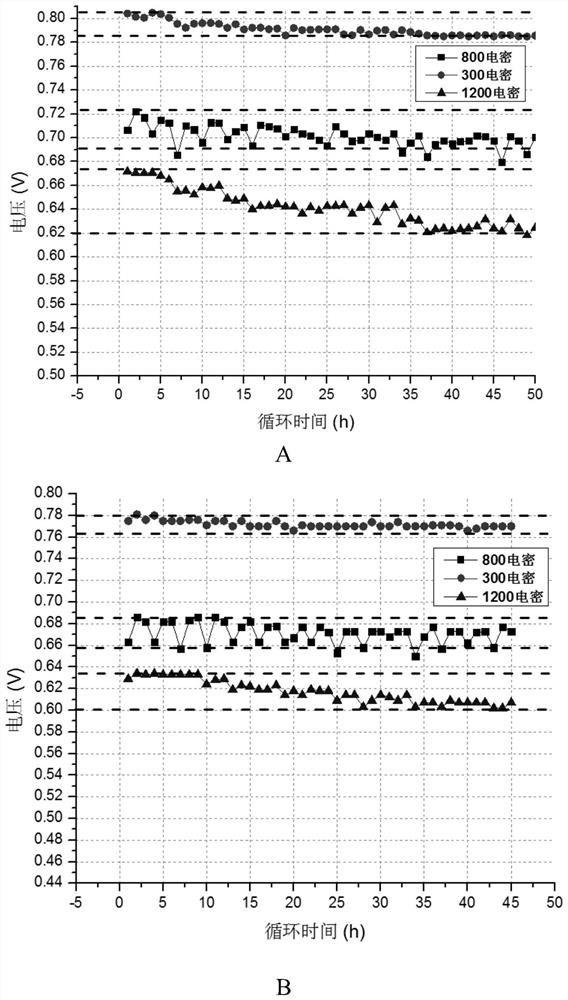

Embodiment 1

[0038] (1) Preparation of hydrophilic layer slurry:

[0039]1) Take by weighing 20% platinum content, TEC10EA20E of the precious metal catalyst TANAKA brand (Tanaka Precious Metals Group) with high durability of graphitization and 5% by mass percentage of DuPont's d520 ionic polymer solution are stirred and mixed. In terms of mass ratio, the TEC10EA20E in TEC10EA20E Carbon: ionic polymer = 1:1, stirring time 30min;

[0040] 2) Then add the hydrophilic solvent Solvay D83 solution (the brand is solvay, the model is D83-24B) with a mass percentage of 8%. In terms of mass ratio, carbon in TEC10EA20E: hydrophilic agent = 1: 2, and stir for 20 minutes;

[0041] 3) Then the whole body is ultrasonically homogenized for 40 minutes for later use;

[0042] (2) Preparation of the first hydrophobic layer slurry:

[0043] 1) take by weighing 50% platinum content, the TEC10E50E of the noble metal catalyst TANAKA brand of high specific surface area is the d520 ionomer solution stirring an...

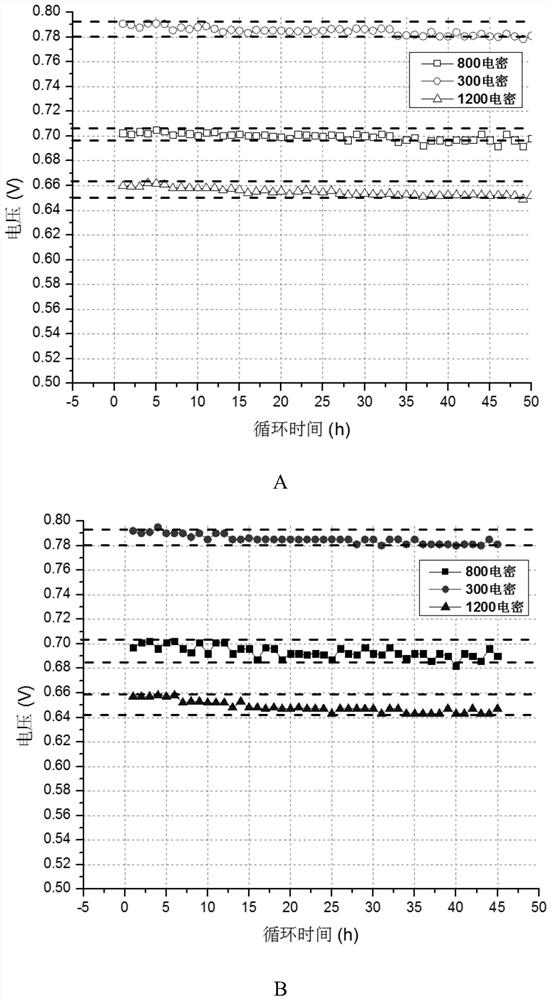

Embodiment 2

[0055] (1) Preparation of hydrophilic layer slurry:

[0056] 1) Take by weighing 20% platinum content, the TEC10EA20E of TANAKA brand of the precious metal catalyst TANAKA of graphitization high durability is mixed with the d520 ionomer solution of Dupont, in terms of mass ratio, carbon in TEC10EA20E: ionomer=1: 0.7, stir Time 20min;

[0057] 2) Then add Solvay D83 solution with a mass percentage of hydrophilic solvent of 8%, in terms of mass ratio, carbon in TEC10EA20E:hydrophilic agent=1:2, and stir for 20min;

[0058] 3) Then the whole body is ultrasonically homogenized for 40 minutes for later use;

[0059] (2) Preparation of the first hydrophobic layer slurry:

[0060] 1) take by weighing 50% platinum content, the TEC10E50E of the noble metal catalyst TANAKA brand of high specific surface area is the d520 ionomer solution stirring and mixing of 5% Dupont by mass percent, by mass ratio, the carbon in TEC10E50E: ionomer= 1:0.6, stirring time 30min;

[0061] 2) Then ad...

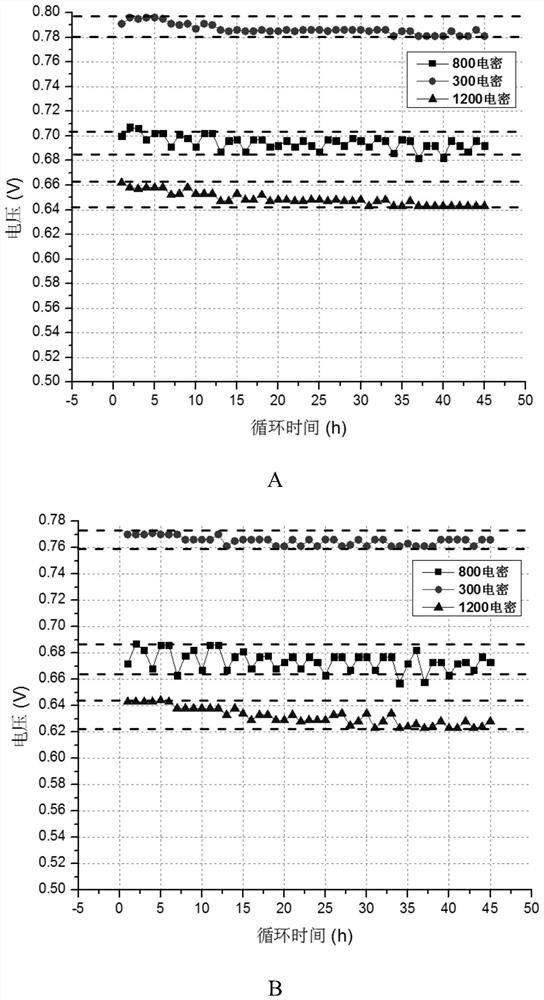

Embodiment 3

[0072] (1) Preparation of hydrophilic layer slurry:

[0073] 1) Take by weighing 20% platinum content, the TEC10EA20E of TANAKA brand of the precious metal catalyst TANAKA of graphitization high durability and the d520 ionic polymer solution of Du Pont are stirred and mixed, by mass ratio, the carbon in TEC10EA20E: ionic polymer=1: 10, stir Time 40min;

[0074] 2) Then add Solvay D83 solution with a mass percentage of hydrophilic solvent of 8%, in terms of mass ratio, carbon in TEC10EA20E:hydrophilic agent=1:10, and stir for 20min;

[0075] 3) Then the whole body is ultrasonically homogenized for 40 minutes for later use;

[0076] (2) Preparation of the first hydrophobic layer slurry:

[0077] 1) take by weighing 50% platinum content, the TEC10E50E of the precious metal catalyst TANAKA brand of high specific surface area is the d520 ionomer solution stirring and mixing of 5% Dupont by mass percent, by mass ratio, carbon in TEC10E50E: ionomer= 1:10, stirring time 40min;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com