Organic solvent-resistant ink for thermal sensing ribbon, release layer and preparation method of organic solvent-resistant ink

A technology resistant to organic solvents and organic solvents, applied in the field of thermal sensing ribbons, can solve the problems of easy shedding of organic solvents and restrictions on the promotion of thermal printing, achieve good alcohol resistance, improve the resultant force of adhesion, and improve scratch resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

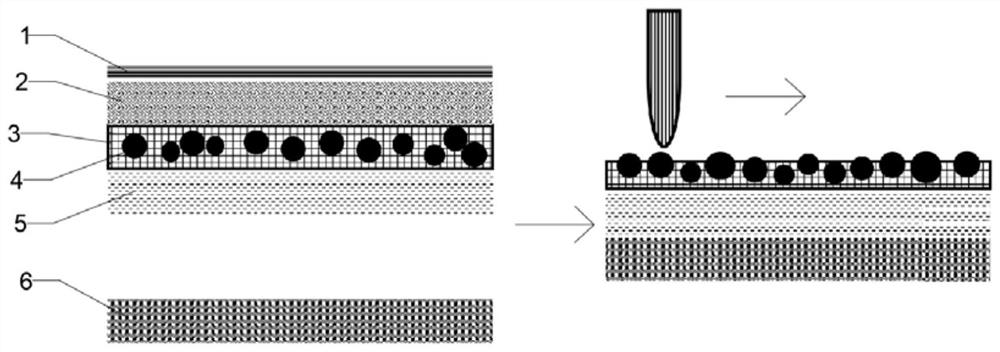

Method used

Image

Examples

Embodiment 1

[0031] Example 1 (The molecular weight of the saturated polyester resin used in the ink layer is 8000, and the organic solvent used in the release layer is cyclohexanone)

[0032] An organic solvent-resistant ink for a thermal sensing ribbon, a release layer, and a preparation method, the thermal sensing ribbon-resistant organic solvent ink comprises: saturated polyester resin 35 g (molecular weight 8000, Tg point 65°C), Lubricant Moisture 17000 2 g, carbon black 10 g, ternary chloroacetate resin 40 g, butanone 300 g. The matching release layer includes: 10 g of silica microspheres, 70 g of polymethyl methacrylate, 30 g of polytetrafluoroethylene wax particles, and 400 g of cyclohexanone.

[0033] A preparation method of organic solvent-resistant ink for thermal sensing ribbon and release layer, comprising the following steps:

[0034] 1) Weigh 35 g saturated polyester resin (molecular weight 8000, Tg point 65°C), 40 g ternary chloroacetate resin, 10 g carbon black, and 2 g L...

Embodiment 2

[0040] Example 2 (the molecular weight of the saturated polyester resin used in the ink layer is 10,000, and the organic solvent used in the release layer is butanone)

[0041] An organic solvent-resistant ink for a thermal sensing ribbon, a release layer, and a preparation method, the thermal sensing ribbon-resistant organic solvent ink comprises: saturated polyester resin (molecular weight 10000, Tg point 60° C.) 40 g, Lubo Moisture 17000 2 g, carbon black 11 g, ternary chloroacetate resin 45 g, butanone 400 g. The matching release layer includes: 10 g of silica microspheres, 70 g of polymethyl methacrylate, 30 g of polytetrafluoroethylene wax particles, and 400 g of methyl ethyl ketone.

[0042] A preparation method of organic solvent-resistant ink for thermal sensing ribbon and release layer, comprising the following steps:

[0043] 1) Weigh 40 g of saturated polyester resin (molecular weight 10000, Tg point 60°C), 45 g of ternary chloride resin, 11 g of carbon black, and...

Embodiment 3

[0049] Example 3 (the molecular weight of the saturated polyester resin used in the ink layer is 15,000, and the organic solvent used in the release layer is cyclohexanone and methyl isobutyl ketone)

[0050] An organic solvent-resistant ink for a thermal sensing ribbon, a release layer, and a preparation method, the thermal sensing ribbon-resistant organic solvent ink comprises: saturated polyester resin (molecular weight 15000, Tg point 89°C) 45 g, Lubo Moisture 17000 2 g, carbon black 13 g, ternary chloroacetate resin 50 g, butanone 500 g. The matching release layer includes: 10 g of silica microspheres, 70 g of polymethyl methacrylate, 30 g of polytetrafluoroethylene wax particles, 200 g of cyclohexanone and 200 g of methyl isobutyl ketone.

[0051] A preparation method of organic solvent-resistant ink for thermal sensing ribbon and release layer, comprising the following steps:

[0052] 1) Weigh 45 g saturated polyester resin (molecular weight 15000, Tg point 89°C), 50 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com