Instant sea cucumber with good storage stability

A technology of sea cucumber and celery juice, which is applied in food science, food ingredients containing natural extracts, and preservation of meat/fish with chemicals, etc. High sensory acceptance, improved stability and taste, and improved product competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation steps of the celery juice cross-linking agent are as follows: after washing the celery, adding pure water for homogenization to obtain celery tissue homogenate; then filtering the celery tissue homogenate to obtain celery juice; then boiling the celery juice and filtering to obtain celery Juice cross-linking agent;

[0032] A specific preparation method is to wash the celery and place it in a homogenizer with pure water at a ratio of 15:1-25:1 (w / v), and process it at 5000-20000r / min for 2-3min to obtain a celery tissue uniform. Serum, filter celery tissue homogenate with 100-400 mesh gauze to obtain celery juice, boil celery juice at 100°C for 2-3 min and filter (100-400 mesh gauze) as celery cross-linking agent extract.

[0033] The preparation steps of the cucumber juice cross-linking agent are as follows: after washing the cucumbers, adding pure water for homogenization to obtain cucumber tissue homogenate; then filtering the cucumber tissue homogena...

Embodiment 1

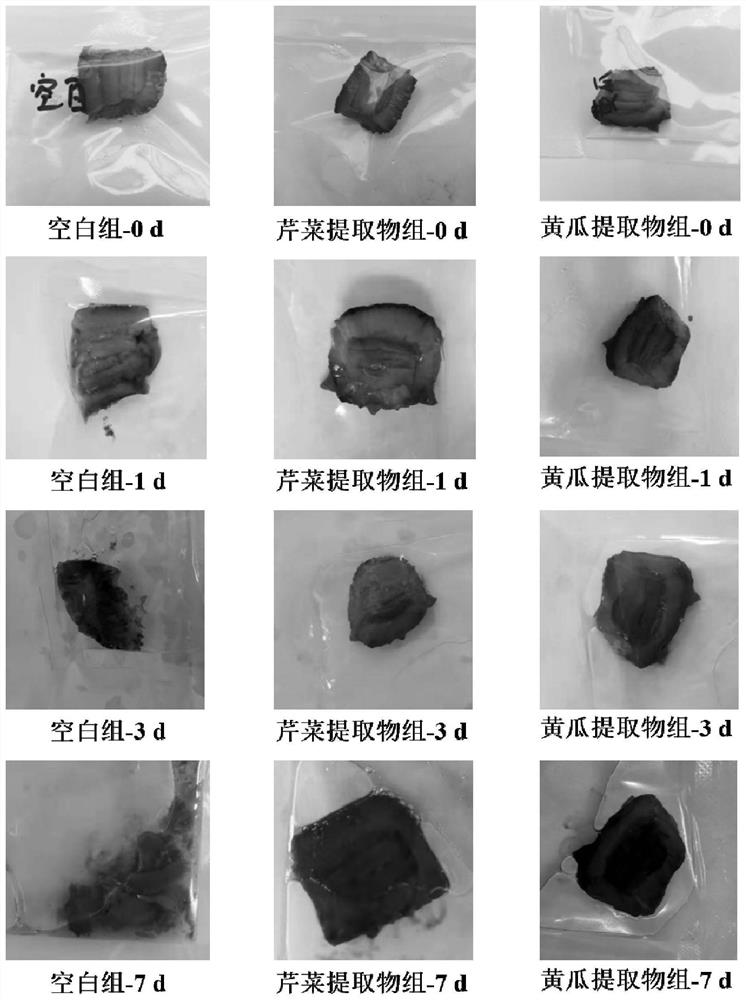

[0040] Fresh sea cucumber is used as the main raw material, celery and cucumber extracts are used as cross-linking agents, and the products are made through pretreatment, blanching and shaping, enzyme inactivation, cross-linking agent treatment, high temperature and high pressure sterilization, and packaging.

[0041] Specific steps are as follows:

[0042] Select fresh sea cucumbers with uniform quality and similar size, open about 2cm in the tail, take out the internal organs and sediment, and rinse with tap water and pure water 3 times respectively.

[0043] Blanching and setting: The washed sea cucumber was placed in a 65° C. water bath (sea cucumber: water=1:20, w / v) for 3 minutes to make it shaped.

[0044] Enzyme inactivation: The shaped sea cucumber was quickly taken out, and then placed in a water bath at 95°C for 10 minutes (sea cucumber: water = 1:20, w / v).

[0045]Cross-linking treatment: According to the ratio of sea cucumber: cross-linking agent = 1:20 (w / v), th...

Embodiment 2

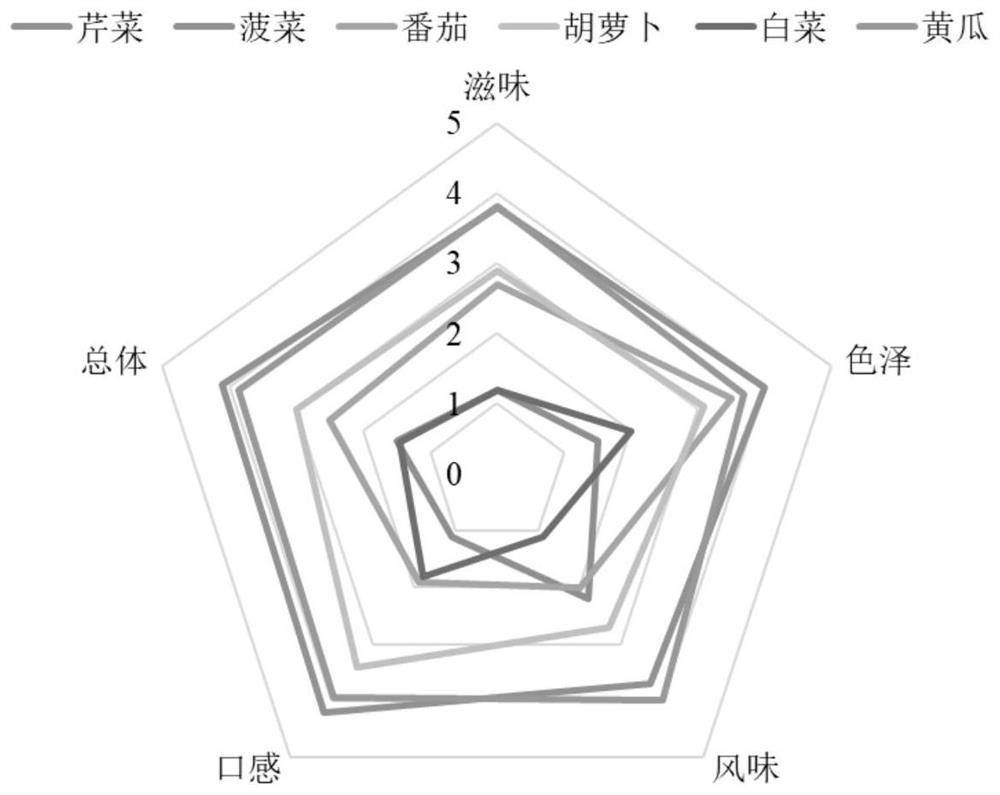

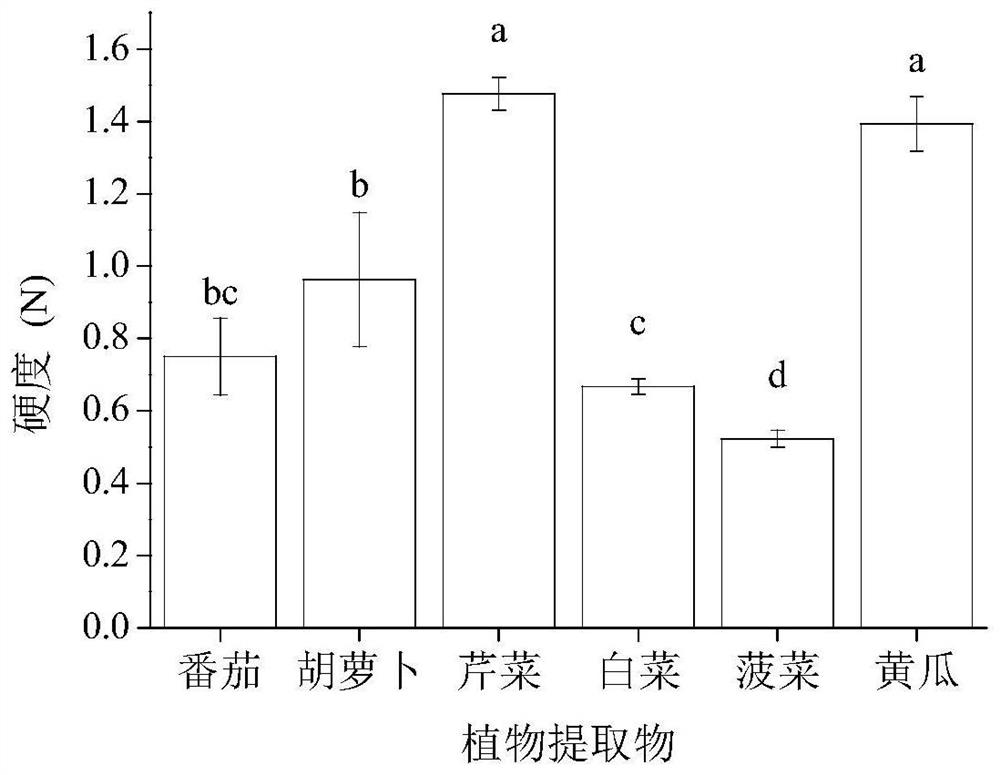

[0049] Select fresh and live sea cucumbers with uniform quality and similar size, open about 2cm in the tail, take out the internal organs and sediment, and rinse with tap water and purified water 3 times respectively. The rinsed sea cucumbers were placed in a 60° C. water bath (sea cucumber: water=1:20 (w / v)), and heated in a water bath for 3 minutes to set the shape. The shaped sea cucumber was quickly taken out, and then placed in a water bath at 100° C. for 10 min (sea cucumber: water = 1:20 (w / v)). Then, put the sea cucumber into the cross-linking agent (wash the spinach / tomato / carrot / cabbage respectively, and then place it in a tissue grinder for 3 min at 5000 r / min to obtain spinach / tomato / carrot / cabbage juice, boil and filter it as a cross-linking agent. cross-linking agent). Finally, each piece of sea cucumber was individually packaged and sealed using a high-temperature retort bag, and placed in a back pressure sterilizer. The sterilization procedure was as follows:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com