V2O5/C3N4 composite photocatalyst as well as preparation method and application thereof

A technology of C3N4 and composite light, which is applied in the field of photocatalysis, can solve the problems of long degradation time of organic dyes, complicated preparation methods, and low degradation efficiency, and achieve excellent photocatalytic degradation activity, solve dye pollution, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

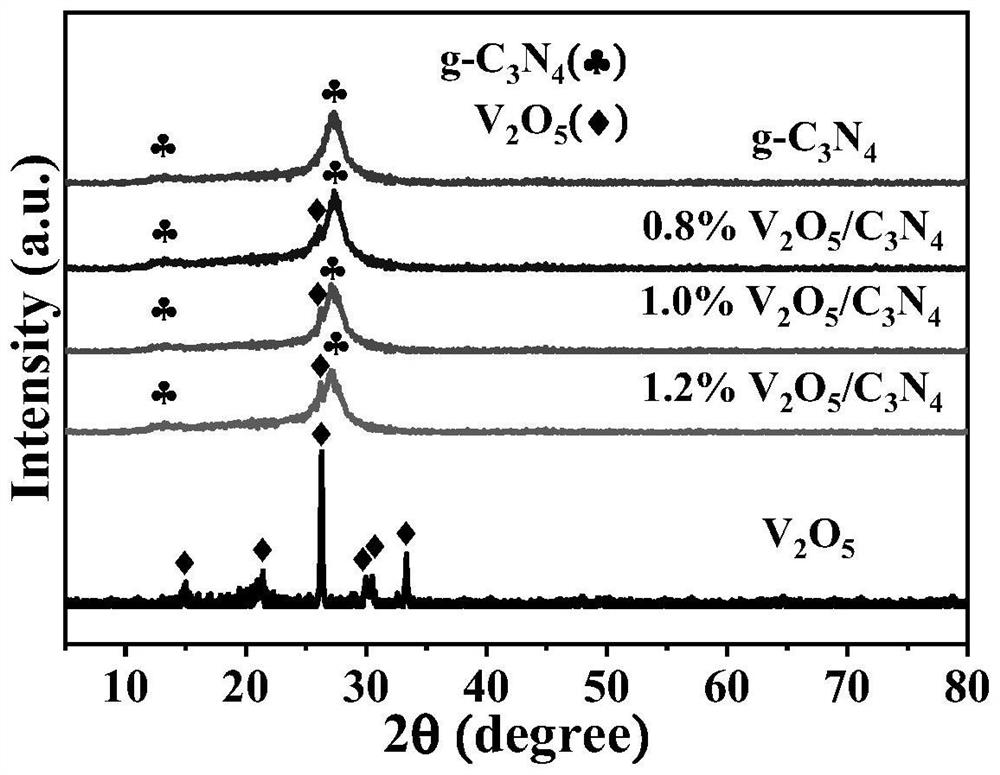

[0026] Embodiments of the present invention provide a V 2 O 5 / C 3 N 4 The preparation method of composite photocatalyst comprises the following steps:

[0027] a. Filter and dilute the failed vanadium battery electrolyte;

[0028] b, adding activated carbon adsorbent to the diluted electrolyte, and performing vibration treatment to obtain vanadium-containing activated carbon after adsorption, filtration and drying;

[0029] c. Add melamine to the vanadium-containing activated carbon, after grinding and mixing, the mixed sample is calcined in one step to obtain V 2 O 5 / C 3 N 4 composite photocatalyst.

[0030] A V according to an embodiment of the present invention 2 O 5 / C 3 N 4In the preparation method of the composite photocatalyst, in step a, the failed vanadium battery electrolyte includes a positive electrode electrolyte mainly composed of tetravalent vanadium and pentavalent vanadium and / or a negative electrode electrolyte composed of divalent vanadium and ...

Embodiment 1

[0037] a V 2 O 5 / C 3 N 4 The preparation method of composite photocatalyst comprises the following steps:

[0038] Take 1L of the vanadium battery electrolyte that has failed, filter to remove solid insolubles and suspended solids; then dilute it and place it in a conical flask, and measure the total vanadium ion concentration in the electrolyte by potentiometric titration to 1.4×10 -3 M; Weigh 0.05g of activated carbon and add it to the conical flask. After mixing evenly, place the conical flask in a constant temperature shaker, shake it at 20°C for 24 hours, and filter it; then put it in an oven for drying to obtain vanadium-containing Activated carbon powder.

[0039] Weigh 22g of melamine, place the melamine and the above-mentioned vanadium-containing activated carbon powder in an agate mortar, fully grind and evenly put it into a crucible; then place the crucible in a muffle furnace, and heat up to 5°C / min. 500 ℃, hold for 5h; after cooling to room temperature, get ...

Embodiment 2

[0042] a V 2 O 5 / C 3 N 4 The preparation method of composite photocatalyst comprises the following steps:

[0043] Take 1L of the vanadium battery electrolyte that has failed, filter to remove solid insolubles and suspended solids; then dilute it and place it in a conical flask, and measure the total vanadium ion concentration in the electrolyte by potentiometric titration to 1.4×10 -3 M; then weigh 0.05g of activated carbon and add it to the conical flask, after mixing evenly, place the conical flask in a constant temperature shaker, shake it at 30°C for 18 hours, and filter it; then put it in an oven for drying to obtain vanadium-containing Activated carbon powder.

[0044] Weigh 17.6 g of melamine, place the melamine and the above-mentioned vanadium-containing activated carbon powder in an agate mortar, fully grind them evenly, and put them into a crucible; then place the crucible in a muffle furnace, and heat up at a heating rate of 5°C / min. to 550°C and kept for 4h;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com