Preparation method of multi-element transition metal composite environment restoration material

An environmental remediation, transition metal technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve problems such as easy generation of iron sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to specific embodiments and accompanying drawings to help understand the content of the present invention.

[0021] A preparation method of a multi-element transition metal composite environmental repair material provided by the present invention comprises the following steps:

[0022] S1: CuSO 4 ·5H 2 O and FeCl 3 ·6H 2 O is stirred at a ratio of 2:1 to complete the dissolution in deionized water;

[0023] S2: Slowly add NaOH solution and Na dropwise 2 CO 3 The solution was subjected to co-precipitation reaction. After complete precipitation, it was incubated at 60 °C for 4 hours, then suction filtered, and washed with deionized water and absolute ethanol in sequence. After washing, it was dried in vacuum at 70 °C for 4 hours to obtain a blue-gray solid. ;

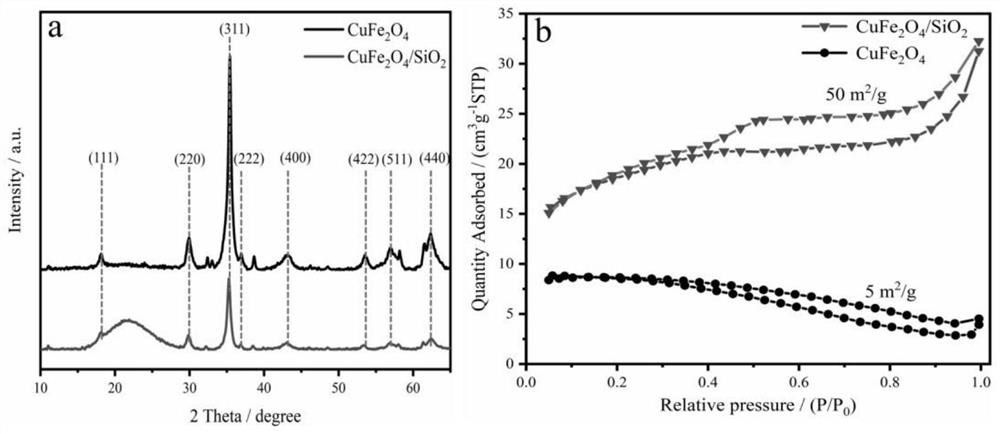

[0024] S3: put the blue-gray solid obtained in S2 into a muffle furnace for calcination, the calcination temperature is 500°C, and the cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com