Spherical high-density micro-nano-scale acid-soluble weighting material as well as preparation method and application thereof

A weighted material and high-density technology, which is applied in the fields of petroleum exploration and rock and soil excavation, can solve problems such as stress sensitive damage, cracks that are difficult to restore to their original state, and reservoir damage, etc., and achieve low flowback pressure, easy flowback, and good suspension Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

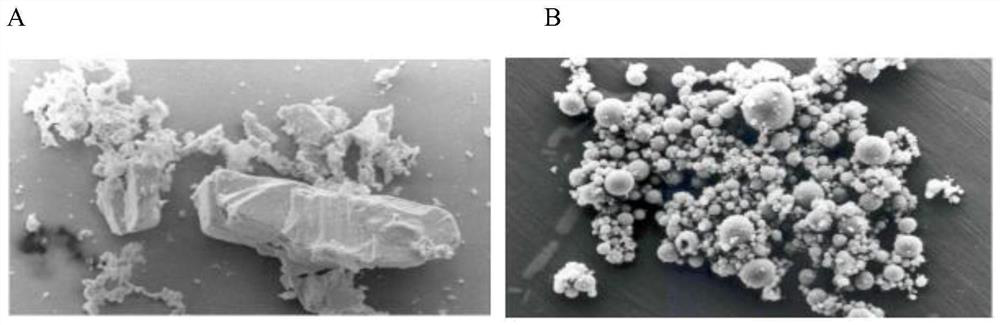

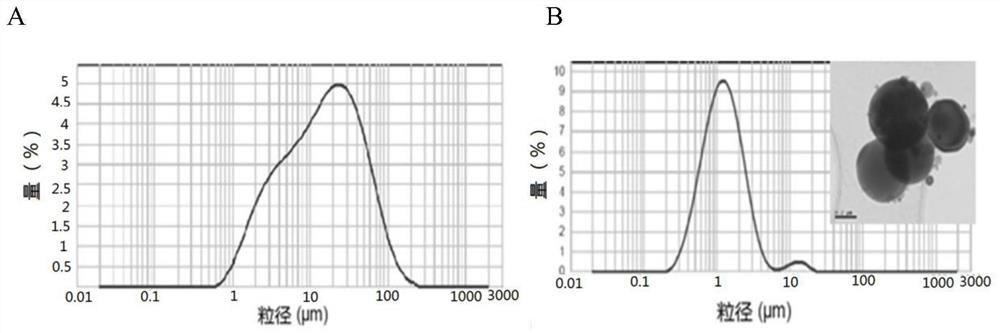

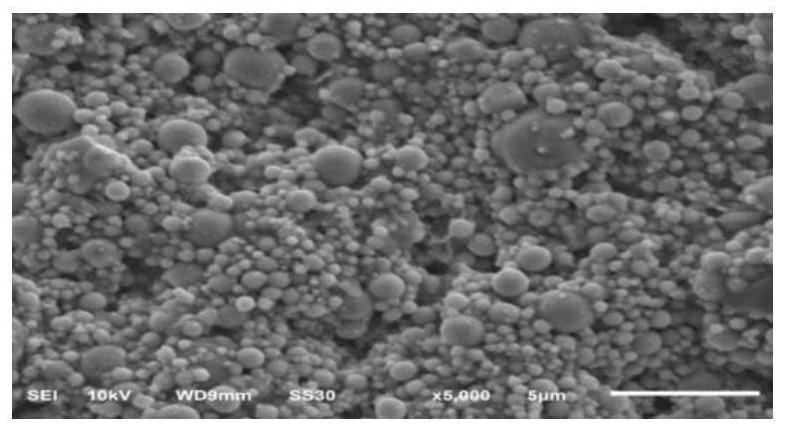

[0031]According to a typical embodiment of the present invention, a method for preparing the above-mentioned spherical high-density micro-nano acid-soluble weighting material is provided. The preparation method includes the following steps: in parts by mass, mixing 30-70 parts of nano-scale manganese tetroxide, 30-65 parts of micro-scale manganese tetroxide, and 0-5 parts of dispersant to obtain spherical Density micro-nano acid-soluble weighting material.

[0032] According to a typical embodiment of the present invention, an application of the above weighting material in petroleum exploration or geotechnical excavation is provided, wherein the weighting material can reduce the high temperature and high pressure filtration loss of all oil-based fluids to less than 5ml (high temperature and high pressure filter). The loss can be measured by the national standard).

Embodiment 1

[0035] Preparation of nano-scale manganese tetroxide: take 50 parts by mass of 100 mesh black manganese ore powder and 20 parts of 10mol / L sodium hydroxide solution, after stirring evenly, pass nitrogen 0.5-0.7MPa, add 10 parts of octanol, 1 part of butanol After 3-4 hours of constant temperature stirring reaction, cooling, filtering, washing, and pyrolysis at a thermal decomposition temperature of 900 °C for 1 hour at high temperature, it can be obtained;

[0036] Preparation of micron-sized manganese tetroxide: by volume ratio, under the condition of oil bath at 98°C, 40 parts of 0.5mol / LMnSO 4 Solution, 25 parts of ammonia water, with mild stirring, pH=10 or so, stirring time is 0.5h. Continue to add 10 parts of 95% ethanol and 6 parts of 10% H dropwise 2 O 2 ; After cooling, filter, wash, and keep at 110°C in a blast drying oven without blasting for 5h.

[0037] Mix the finished product with 30 parts of nano-scale manganese tetroxide, 65 parts of micro-scale manganese t...

Embodiment 2

[0044] Preparation of nano-scale manganese tetroxide: take 60 parts by mass of 100-mesh black manganese ore powder and 25 parts of 10mol / L sodium hydroxide solution, after stirring evenly, pass nitrogen 0.5-0.7MPa, add 5 parts of octanol, 5 parts of butanol After 3-4 hours of constant temperature stirring reaction, filtered, washed, and pyrolyzed at a thermal decomposition temperature of 900 °C for 1 hour, the finished product was obtained;

[0045] Preparation of micron-sized manganese tetroxide: 60 parts of 0.5mol / LMnSO in an oil bath at 98°C by volume ratio 4 The solution, 30 parts of ammonia water, was stirred gently, pH=10, and the stirring time was 0.5h. Continue to add 10 parts of 95% ethanol and 10 parts of 10% H dropwise 2 O 2 ; After cooling, filter, wash, and keep at 120°C in a blast drying oven without blasting for 5h.

[0046] Mix the finished product with 55 parts of nano-scale manganese tetroxide, 40 parts of micro-scale manganese tetroxide, and 5 parts of Sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com