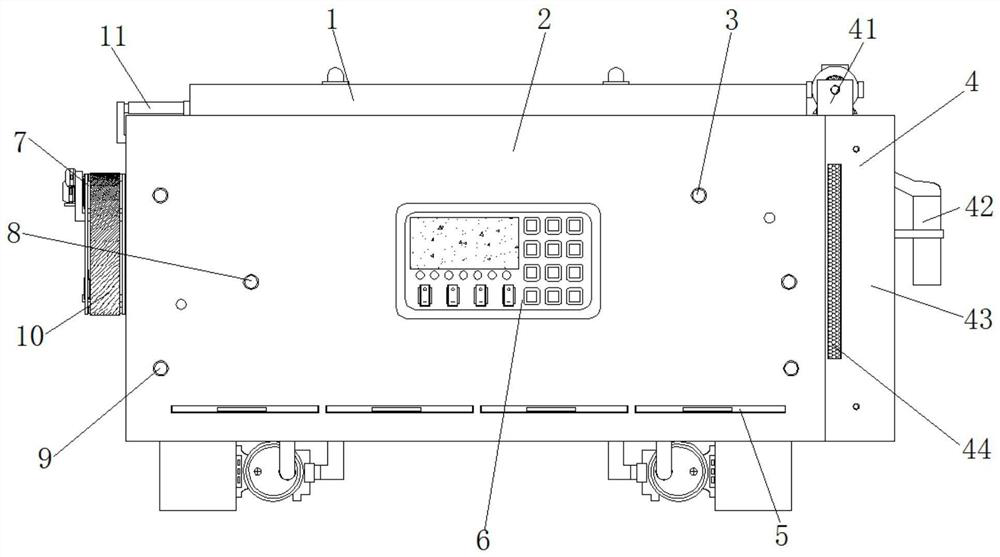

Automatic assembly process and equipment for mechanical sealing element of internal combustion engine

A technology for mechanical seals and assembly equipment, which is applied in the field of automatic assembly technology and equipment for internal combustion engine mechanical seals, can solve the problems of heat loss, large floor space, and increased energy consumption of internal combustion engine mechanical seal drying equipment, etc., to achieve reduction Dissipate heat energy, reduce floor space, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

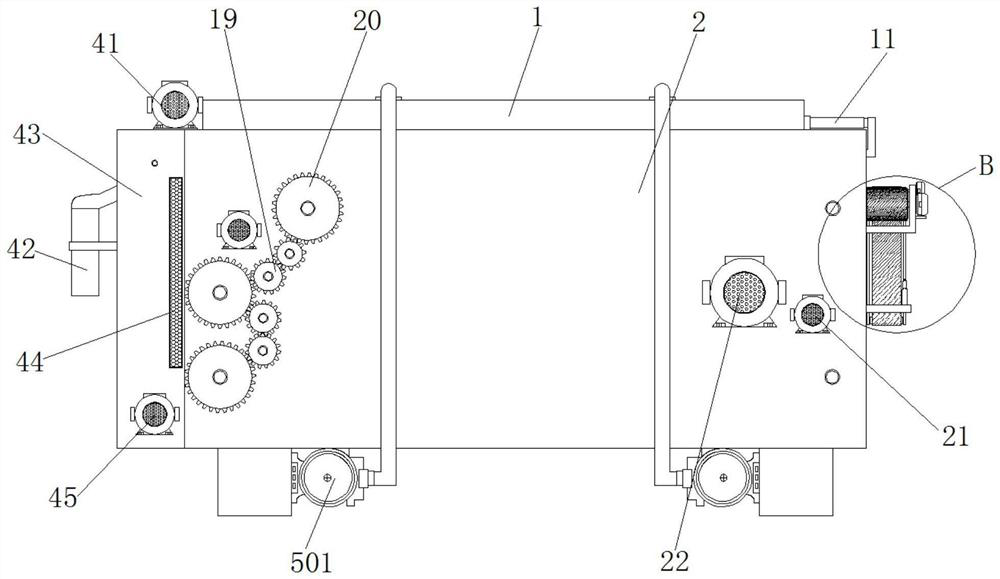

[0056] Example 1, in the assembly process to complete the combination of various parts, the most important thing in the assembly process is bonding, and 509 glue is used for bonding. 509 glue is a kind of adhesive mixed in proportion. This adhesive can effectively bond rubber and other materials together. After curing, the strength can meet the requirements of use, and it is resistant to corrosion and high temperature. It is the most important step in the entire assembly line. The manufacturing process of this link is summarized as follows. process:

[0057] Base feeding—coating 509 glue inside the base—feeding the rubber bellows assembly—coating 509 glue on the joint surface of the bellows assembly and the static ring—static ring assembly—moving ring assembly assembly—riveting, in this process, the operator controls the glue applicator Bit operation, real-time monitoring of the glue temperature in the manufacturing process, the ambient temperature in the machine, the mixing r...

Embodiment 2

[0058] Example 2, in the blue glue application procedure, a water-based sealant liquid is mainly applied to the surface of the designated part of the base according to the requirements and meets the requirements. In this process, the operator adjusts the blue glue application related mechanical devices and The controller monitors the operation of the equipment in real time, continuously checks the work-in-process, prevents the generation of defective products in time, and ensures the normal operation of the equipment and the products meet the requirements.

Embodiment 3

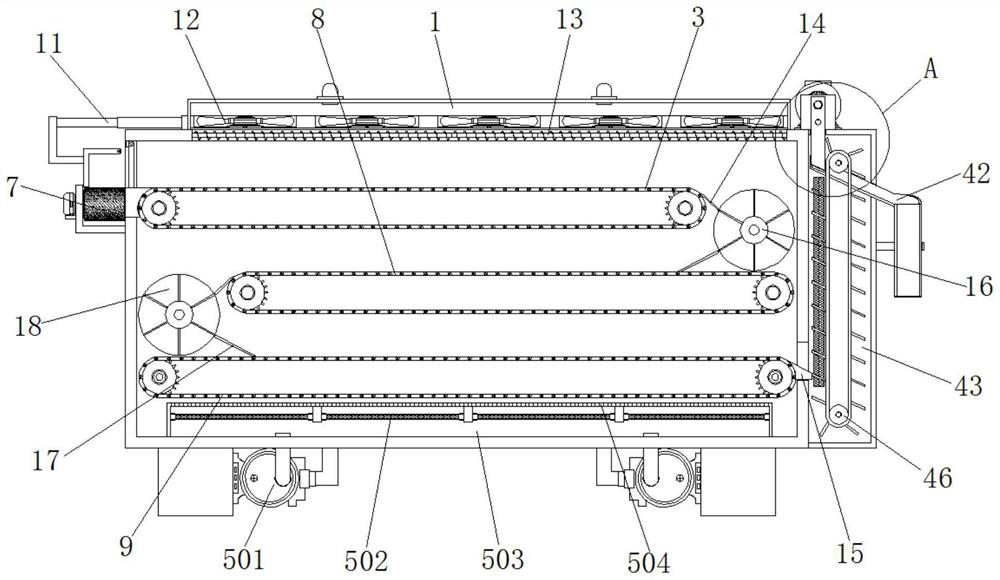

[0059] Example 3, in the drying process, this is a process of heating and air cooling. Appropriate temperature will accelerate the curing of 509 glue, and the finished product in the previous process will enter a tunnel-type dryer. There is enough space to heat up the product in process - heat preservation - air cooling, and complete the drying and air cooling processes within a certain time and temperature environment. This process requires the operator to monitor the temperature controller in real time to ensure that the temperature meets the requirements. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com