Condensed type room temperature vulcanization heat insulation silicone rubber and preparation method thereof

A room temperature vulcanization and condensation type technology, applied in the field of silicone rubber, can solve the problems of base material falling off, elastic body losing elasticity, high temperature of parts, etc., and achieve the effect of improving heat resistance and excellent storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

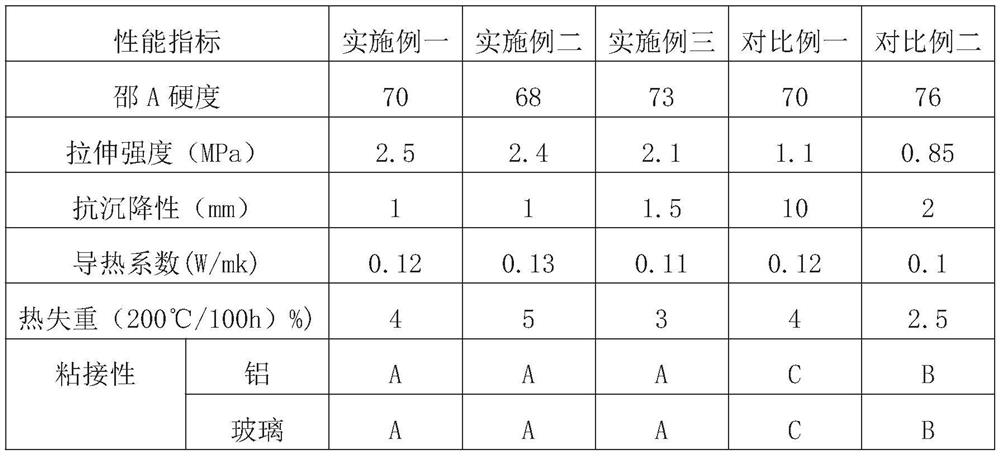

Examples

Synthetic example 1

[0052] Put 1mol of aminopropyltriethoxysilane and 1mol of γ-methacryloxypropyltrimethoxysilane into the reaction kettle, reflux at a constant temperature of 90°C for 1.5h, add 1.5mol of butyl titanate, and raise the temperature to 120°C , Reflux at constant temperature for 3h to obtain the new silane tackifier 1#.

Synthetic example 2

[0054] Put 1mol of aminopropyltriethoxysilane, 1mol of γ-methacryloxypropyltrimethoxysilane, and 1molr-(2,3-glycidoxy)propyltrimethoxysilane into the reactor, After refluxing at a constant temperature at 90°C for 1.5h, add 3mol hexamethyldisilazane, raise the temperature to 140°C and reflux at a constant temperature for 12h to obtain the new silane tackifier 2#.

Synthetic example 3

[0056] Put 1mol of aminopropyltriethoxysilane, 1mol of γ-methacryloxypropyltrimethoxysilane, and 1molr-(2,3-glycidoxy)propyltrimethoxysilane into the reactor, After reflux at constant temperature at 90°C for 1.5h, add 2.3mol butyl titanate, raise the temperature to 120°C, and reflux at constant temperature for 3h to obtain the new silane tackifier 3#.

[0057] Synthesis 1-3 examples are used as tackifiers for the preparation of condensation type room temperature vulcanized silicone rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com