Fluorescent composite fireproof glass and preparation method thereof

A fire-resistant glass and fluorescent technology, applied in chemical instruments and methods, luminescent materials, construction, etc., can solve the problems of distinguishing the fire resistance limit, difficulty, and easy to appear counterfeit products, etc., to achieve low cost of synthetic raw materials, low energy consumption, The effect of good application prospects and potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The invention provides a method for preparing fluorescent composite fireproof glass, comprising the following steps:

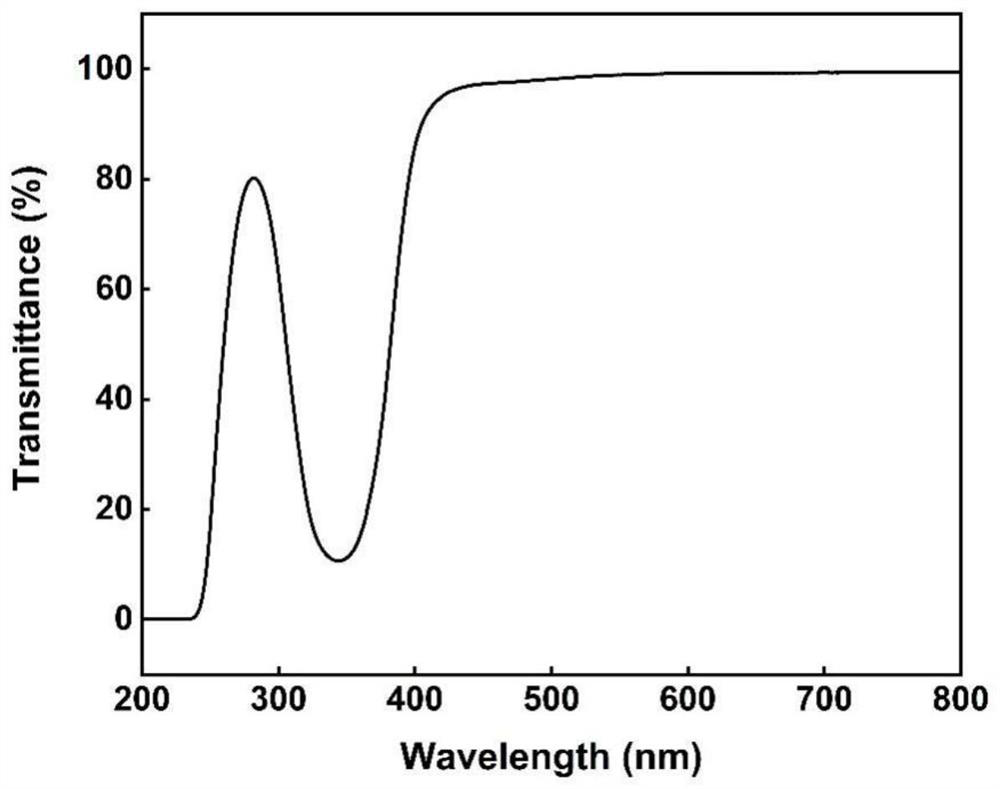

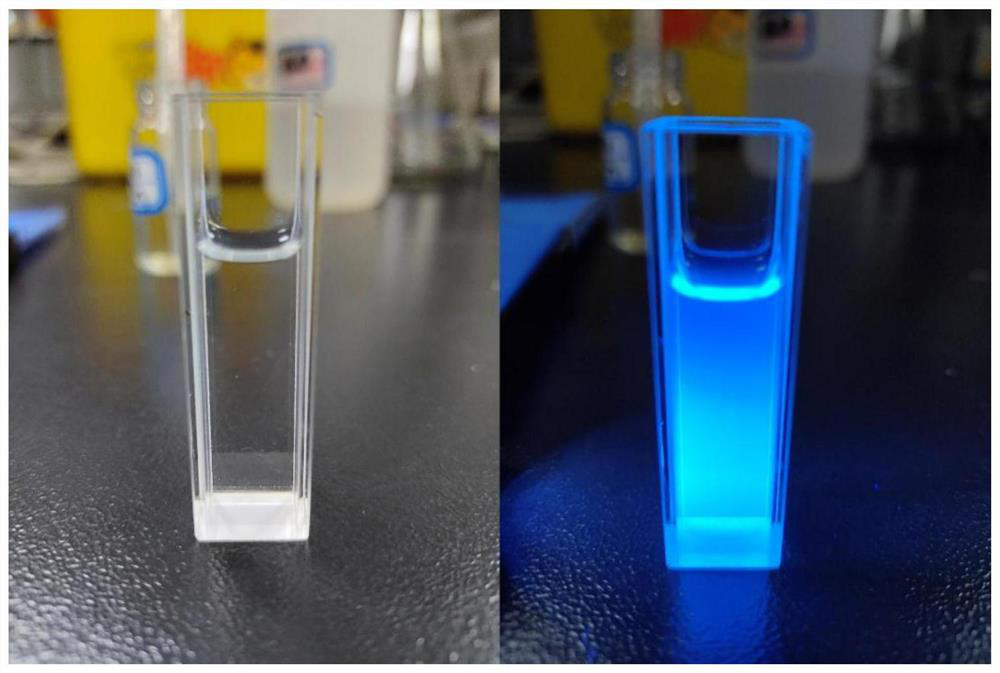

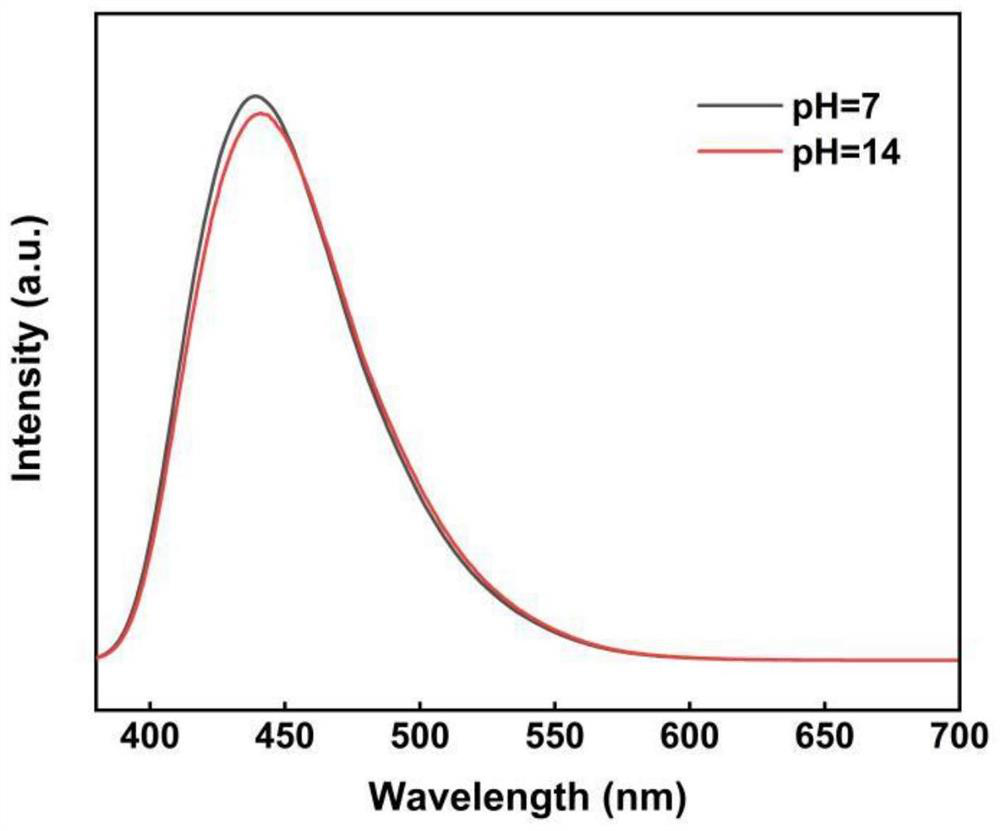

[0031] a) After mixing carbon-based precursors, nitrogen-containing substances, silane coupling agents and water, perform hydrothermal reaction, and obtain nitrogen-hybridized blue-light carbon-based molecular solution after cooling;

[0032] b) mixing the alkaline silica sol and glycerin, and concentrating to remove water of the same quality as the glycerin, and then adding the azed blue-light carbon-based molecular solution and potassium hydroxide aqueous solution obtained in step a) successively to react, Then stir and cool under vacuum conditions to obtain a groutable intermediate liquid;

[0033] c) inject the groutable intermediate solution obtained in step b) into the cavity between the glass interlayers, and obtain fluorescent composite fireproof glass after curing.

[0034] In the invention, the carbon-based precursor, the nitrogen-containing ...

Embodiment 1

[0055] S1. Weigh 0.4 parts by weight of ammonium citrate, 0.2 parts by weight of urea, 0.2 parts by weight of γ-aminopropyltriethoxysilane, and 25 parts by weight of water and mix them in a beaker, stir them ultrasonically to completely mix the materials, and transfer them to a hydrothermal In the kettle, then hydrothermally reacted at 170°C for 1 hour, and then cooled naturally to obtain a nitrogen hybridized blue light carbon-based molecular solution;

[0056] S2. Weigh 100 parts by weight of 50wt% alkaline silica sol and 10 parts by weight of glycerol, mix them uniformly, and concentrate to remove 10 parts by weight of water, and then mix them evenly with 1.5 parts by weight of the nitrogenated blue light carbon-based molecular solution obtained in step S1 , then add 40 parts by weight of 50wt% potassium hydroxide aqueous solution, mix and react at 50°C for 30 minutes, then vacuumize the system, then stir for 10 minutes under vacuum and cool to obtain a groutable intermediat...

Embodiment 2

[0059] Adopt the preparation method that embodiment 1 provides, obtain fluorescent composite fireproof glass; Difference is:

[0060] S1. Weigh 0.4 parts by weight of citric acid, 0.3 parts by weight of ethanolamine, 0.3 parts by weight of γ-aminopropyltriethoxysilane, and 25 parts by weight of water, mix them in a beaker, stir them ultrasonically to make the substances completely mixed, and transfer them to a hydrothermal kettle , then hydrothermally reacted at 170° C. for 2 h, and then cooled naturally to obtain a nitrogen hybridized blue light carbon-based molecular solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com