Method for recycling foundry waste sand based on vertical energy-saving roasting furnace

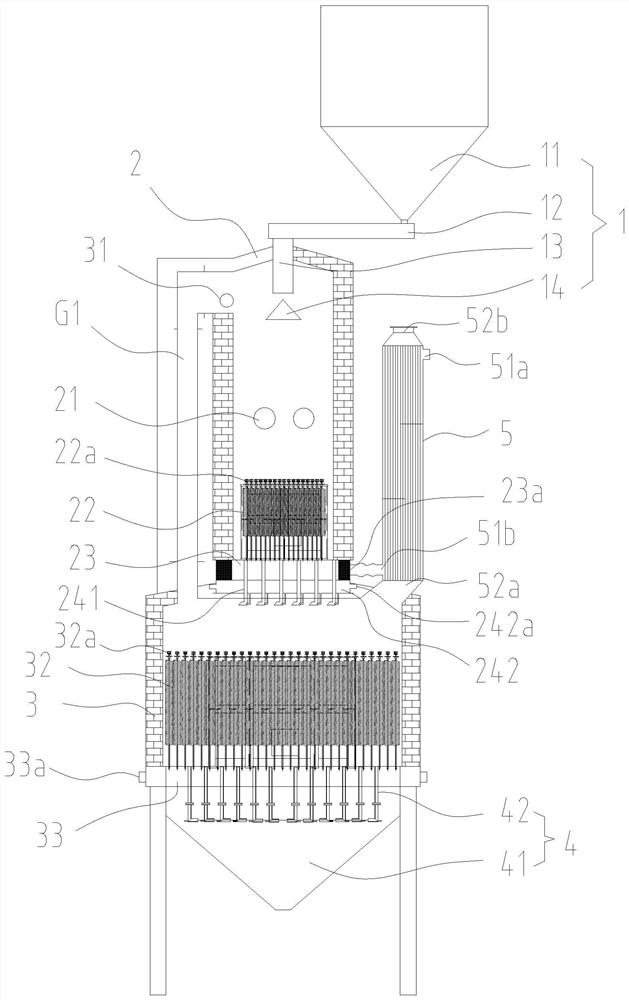

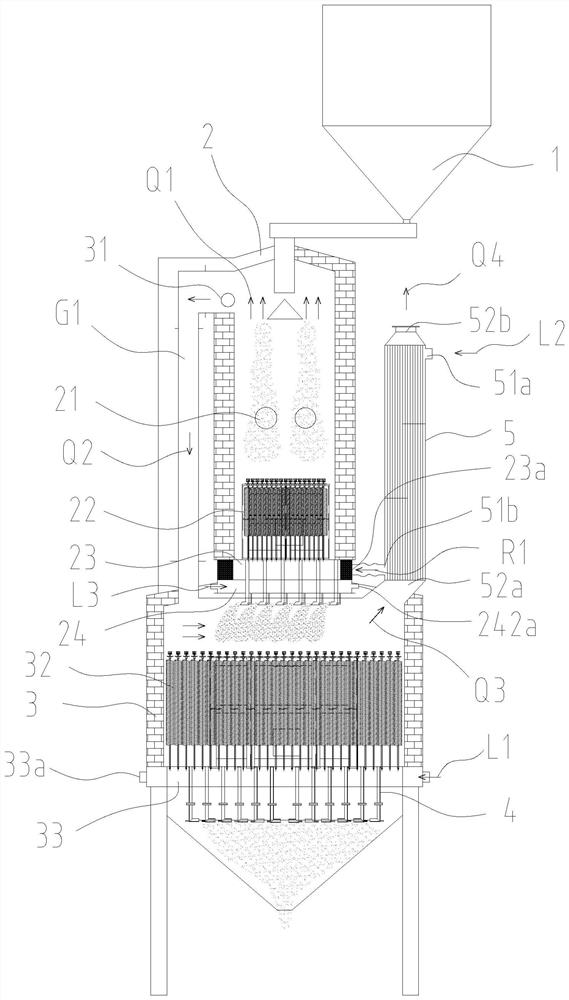

A technology for foundry waste sand and roasting furnace, which is applied in combustion methods, foundry molding equipment, and machinery for cleaning/processing of foundry materials, etc. It can solve the problem of less research on mixed-mould foundry waste sand regeneration technology and cannot meet foundry sand technology. Quality requirements, poor removal of organic impurities by membranes, etc., to achieve high-efficiency roasting treatment effect, avoid exhaust emissions from causing harm to the environment, and exhaust exhaust purification treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] A method for recycling waste foundry sand based on a vertical energy-saving roasting furnace, comprising the following steps:

[0062] S1. The foundry waste sand is crushed, and then the pretreatment waste sand is obtained after magnetic separation and screening;

[0063] S2. The pretreatment waste sand is fully mixed with the acid solution by spraying, and the reaction is carried out for 10-20min while stirring, then washed with water and air-dried; the acid solution is a mixed solution of hydrofluoric acid and 10% sulfuric acid, and the hydrofluoric acid The mass ratio of acid to 10% sulfuric acid is 1:1;

[0064] S3. add brown corundum abrasive in the waste sand after drying, enter the roasting furnace for roasting, the roasting temperature is 700 ° C, and the time is 10min; the addition of the brown corundum abrasive is 6% of the weight of the waste sand; after the roasting finishes Cooling and screening to obtain primary regenerated sand;

[0065] S4. Wet scrubbi...

Embodiment 2

[0067] A method for recycling waste foundry sand based on a vertical energy-saving roasting furnace, comprising the following steps:

[0068] S1. The foundry waste sand is crushed, and then the pretreatment waste sand is obtained after magnetic separation and screening;

[0069] S2. The pretreatment waste sand is fully mixed with the acid solution by spraying, and the reaction is carried out for 10-20min while stirring, then washed with water and air-dried; the acid solution is a mixed solution of hydrofluoric acid and 10% sulfuric acid, and the hydrofluoric acid The mass ratio of acid to 10% sulfuric acid is 2:1;

[0070] S3. add brown corundum abrasive in the waste sand after drying, enter the roasting furnace for roasting, the roasting temperature is 900 ° C, and the time is 5min; the addition of the brown corundum abrasive is 10% of the weight of the waste sand; after the roasting finishes Cooling and screening to obtain primary regenerated sand;

[0071] S4. Wet scrubbi...

Embodiment 3

[0073] A method for recycling waste foundry sand based on a vertical energy-saving roasting furnace, comprising the following steps:

[0074] S1. The foundry waste sand is crushed, and then the pretreatment waste sand is obtained after magnetic separation and screening;

[0075] S2. The pretreatment waste sand is fully mixed with the acid solution by spraying, and the reaction is carried out for 10-20min while stirring, then washed with water and air-dried; the acid solution is a mixed solution of hydrofluoric acid and 10% sulfuric acid, and the hydrofluoric acid The mass ratio of acid to 10% sulfuric acid is 1.5:1;

[0076] S3. in the waste sand after drying, add brown corundum abrasive, enter the roasting furnace for roasting, the temperature of roasting is 800 ° C, and the time is 6min; the addition of the brown corundum abrasive is 7% of the weight of the waste sand; after the roasting finishes Cooling and screening to obtain primary regenerated sand;

[0077] S4. Wet sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com