Test analysis method for rapidly determining four components of heavy oil

A rapid determination and analysis method technology, applied in the direction of weighing by removing certain components, preparation of test samples, etc., can solve problems such as poor separation effect, low recovery rate, overlapping components, etc., to achieve data stability and improve The effect of contrasting, thorough component overlap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A test and analysis method for rapidly measuring the four components of heavy oil, specifically comprising the following steps:

[0041] Step 1. Preparatory work before the test:

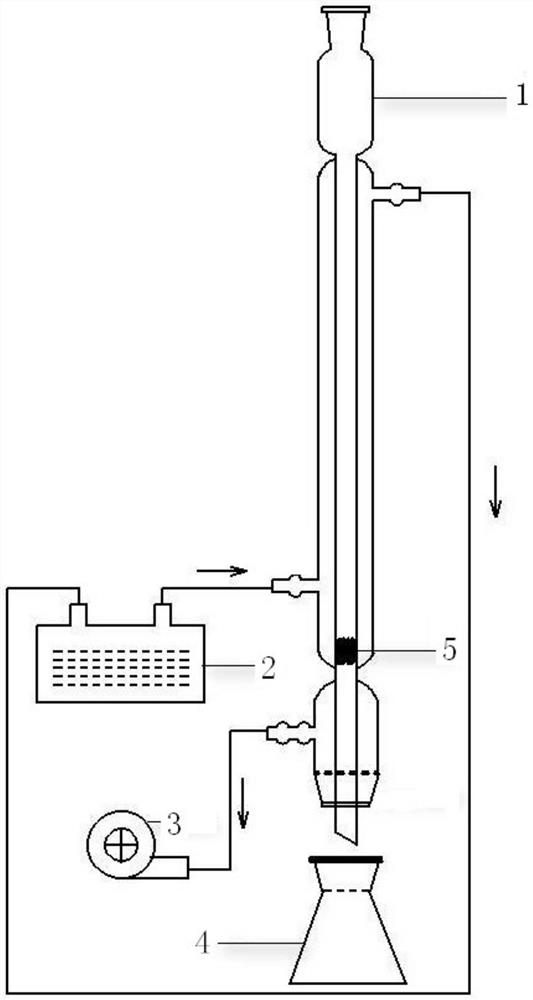

[0042] 1) Install test equipment;

[0043] 2) Activation of Al2O3: take 300g of Al2O3 for neutral 100-mesh chromatography, activate it in a muffle furnace at 500°C for 6h, put it into a glass container after cooling, and add distilled water with 1% mass of Al2O3 , shake well and let it stand for 24 hours for later use;

[0044] 3) Prepare analytically pure n-heptane, analytically pure toluene and analytically pure anhydrous ethanol reagents for use;

[0045] Step 2. Select the hot high-fraction oil separated after the suspension bed hydrogenation as the heavy oil sample, heat it to 110°C, and stir well;

[0046] Step 3. Weigh samples with masses of 1.0108g and 0.9949g respectively and place them in clean centrifuge tubes, marked as m 1 ;

[0047] Step 4. 1) Add 30ml of pure hot n-heptane...

Embodiment 2

[0060] A test and analysis method for rapidly measuring the four components of heavy oil, specifically comprising the following steps:

[0061] Step 1. Preparatory work before the test:

[0062] 1) Install test equipment;

[0063] 2) Activation of Al2O3: take 500g of Al2O3 for neutral 200 mesh chromatography, activate it in a muffle furnace at 525°C for 6h, put it into a glass container after cooling, and add distilled water with 1% mass of Al2O3 , shake well and let it stand for 24 hours for later use;

[0064] 3) Prepare analytically pure n-heptane, analytically pure toluene and analytically pure anhydrous ethanol reagents for use;

[0065] Step 2. Select the vacuum residue as a heavy oil sample, heat it to 140°C, and fully stir it evenly;

[0066] Step 3. Weigh samples with a mass of 1.0664g and 1.0636g respectively and place them in a clean centrifuge tube, marked as m 1 ;

[0067] Step 4, 1) Add 40ml of analytically pure hot n-heptane at 65°C to each of the two centr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com