Micro-plastic aging behavior evaluation method

An evaluation method and technology for microplastics, which can be used in the analysis of materials, material separation, material inspection products, etc., and can solve the problems of lack of microplastic aging evaluation methods and environmental behavior of single microplastics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1: the chloride ion detection method steps of halogen-containing microplastic PVC are as follows:

[0054] (1) Prepare PVC microplastic powder, prepare simulated solutions containing different environmental factors, measure 50 mL of simulated solution into a light tube, add 1 g of PVC microplastics, conduct a simulated light experiment, and add a magnetic stirring rotor to disperse and suspend the plastic particles;

[0055] (2) Take 1 mL of solution with a pipette at 0, 0.5, 1.5, 3, 6, and 12 h respectively, and use an ion chromatograph to detect the chloride ion concentration after dilution;

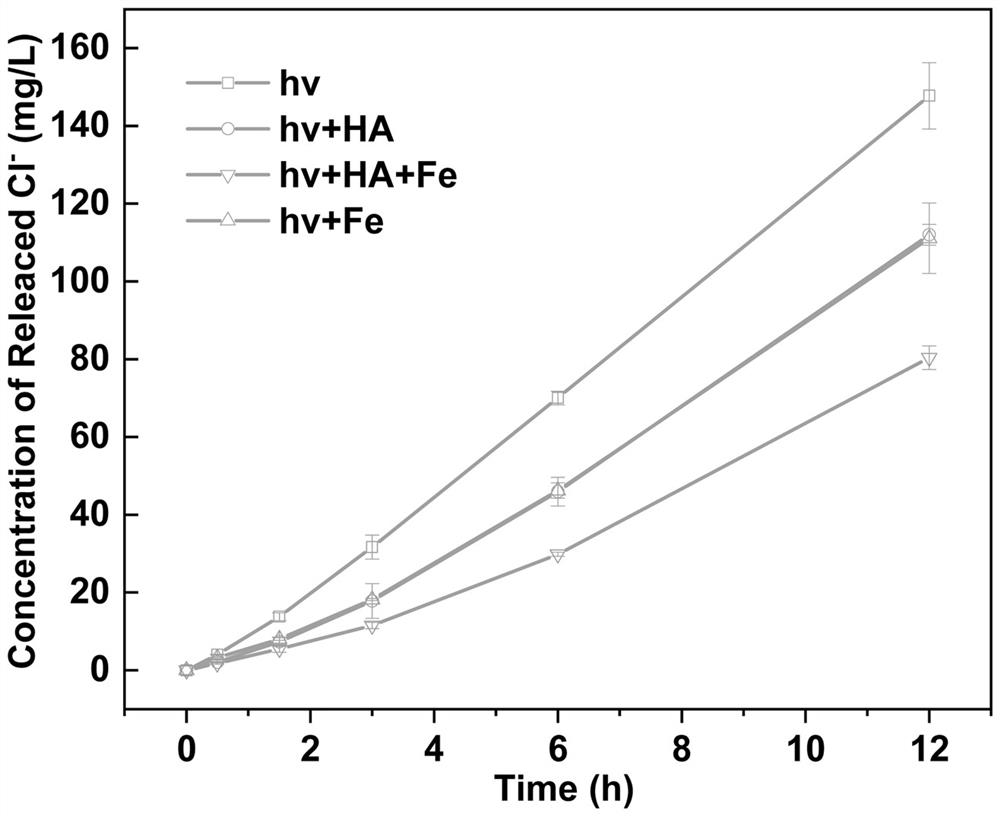

[0056] The change of chloride ion concentration in solution with aging time is shown in figure 1 ,from figure 1 It can be seen that the photoaging process of PVC microplastics is accompanied by the shedding of chlorine. And the simulated aging environment is different, and the degree of chlorine removal is different. Detection of chloride ion concentration in the a...

Embodiment 2

[0057] Embodiment 2: The concrete steps of PET microplastic fluorescence detection are:

[0058] (1) Prepare PET microplastic powder, prepare simulated solutions containing different environmental factors, measure 50 mL of simulated solution into a lighting tube and add 1 g of PVC microplastics to conduct a simulated lighting experiment, and add a magnetic stirring rotor to disperse and suspend the plastic particles;

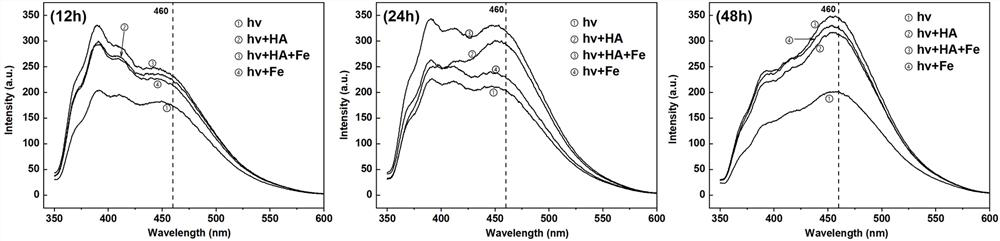

[0059] (2) Collect the PET microplastics in batches of 12, 24, and 48 hours of photoaging, wash and dry them, and detect the fluorescence spectrum of the microplastic powder with a fluorometer. Detection conditions: excitation wavelength 340nm, detection range: 350-600nm, observe the change of fluorescence intensity at 460nm.

[0060] The fluorescence changes of PET microplastics with aging time are shown in figure 2 , figure 2 (a), (b), and (c) are the fluorescence spectra of 12, 24, and 48 hours of aging, respectively. It can be seen from the figure that t...

Embodiment 3

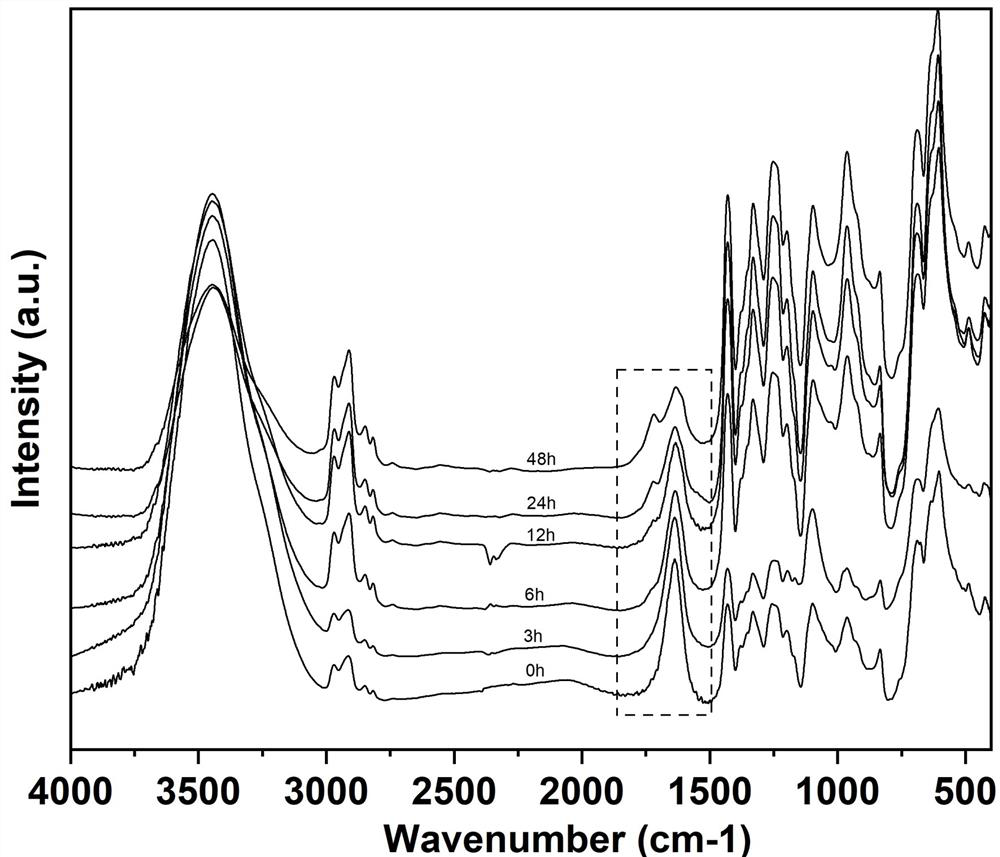

[0061] Example 3: Select the PVC microplastic powder aged by the method in Example 1 to test its infrared spectrum, observe the change of functional groups caused by the aging of the microplastic, and calculate the vinyl index and carbonyl index according to the infrared spectrum data. The corresponding infrared spectrum and index calculation results are shown in image 3 and Figure 4 . from image 3 It can be seen that the absorption peaks of double bonds and carbonyl groups of PVC microplastics change after aging, and the aging behavior of microplastics can be judged by the infrared absorption peaks. In this example, 1430cm is selected -1 The methylene absorption peak at is the reference peak for exponential calculation, from Figure 4 The changes of vinyl index and carbonyl index with aging time can be seen in the results, and the index changes caused by the aging of microplastics can be used to evaluate the aging behavior of microplastics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com