Medical low-density ethylene film surface dust remover

A low-density ethylene, film surface technology, applied in the direction of removing smoke and dust, cleaning methods and utensils, cleaning methods using gas flow, etc., can solve the problems of high labor intensity, inability to block, dust raising, etc., and achieve the effect of reducing dust drift. , Improve the effect of dust removal and avoid the effect of dust drifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

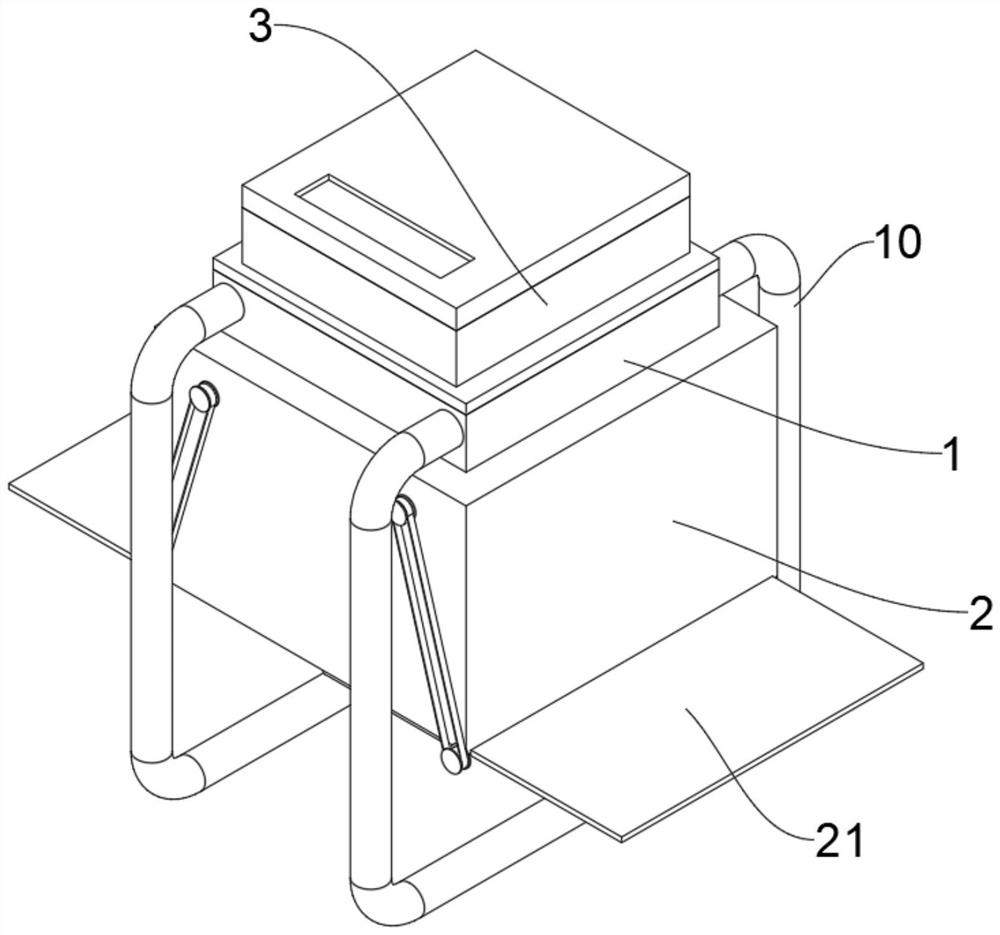

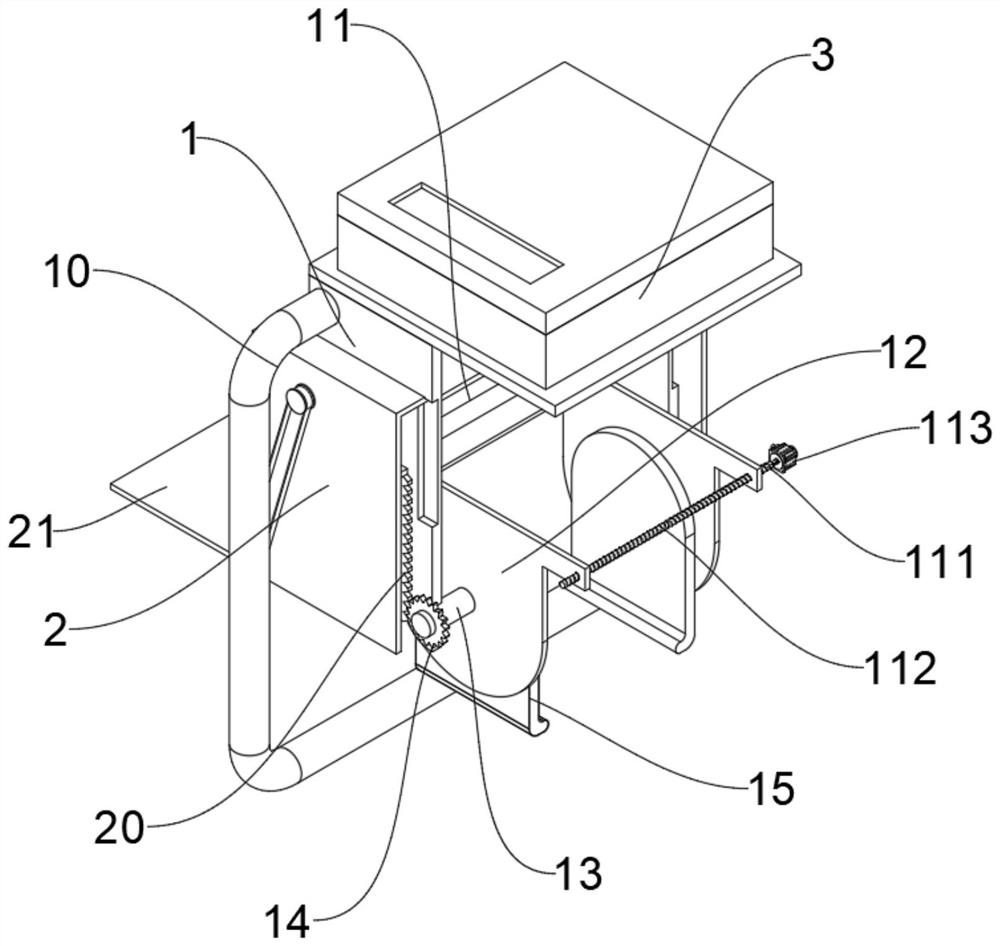

[0038] see Figure 1-Figure 7 As shown in the figure, this embodiment provides a medicinal low-density vinyl film surface dust remover, including a fixed box 1 and a blocking cover 2 slidingly arranged on the outer wall of the fixed box 1. The top of the fixed box 1 is connected with a vacuum box 3, and the vacuum box 3 There is an air pump 310 inside, a chute 11 is provided on the inner wall of the fixed box 1 near the bottom, and two symmetrical slide plates 12 are arranged inside the chute 11, and the inner surface of the slide plate 12 is provided with a splint 15, which can slide the vinyl film through the slide plate 12 , the splint 15 is clamped to fix the vinyl film, and then the air pump 310 is powered on to make it work, and the air pump 310 sucks the dust on the surface of the vinyl film from the inside of the fixed box 1 into the vacuum box 3 for storage;

[0039] In order to improve the clamping stability of the splint 15, a rotating rod 111 is provided inside the...

Embodiment 2

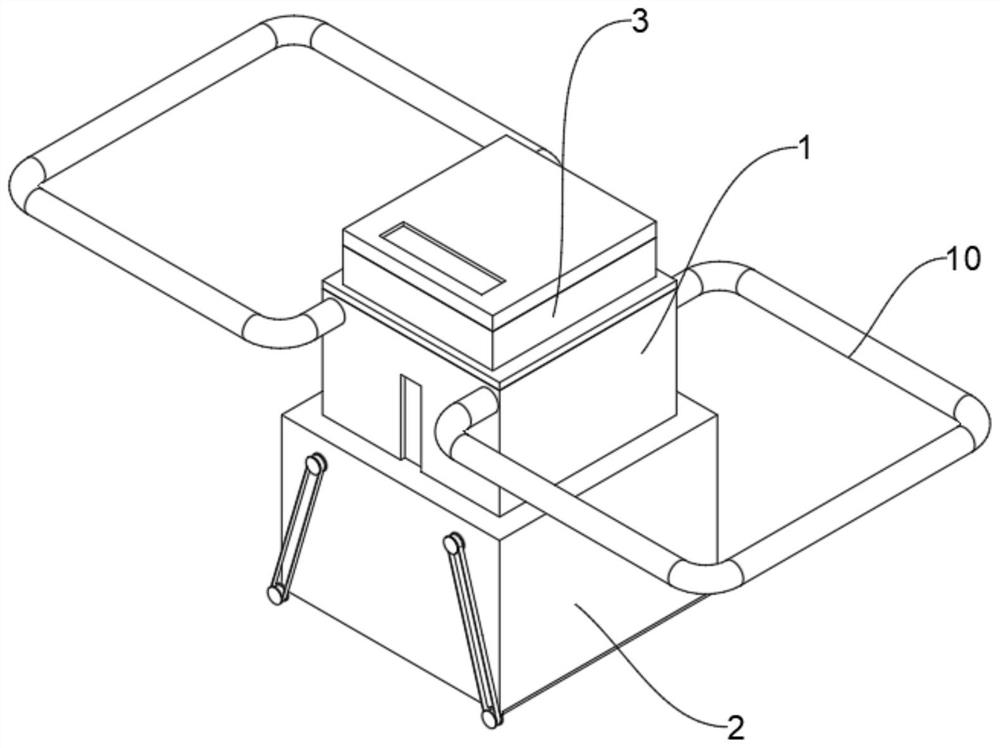

[0048] Considering that the bottom of the blocking cover 2 is open, the dust is easily scattered from the bottom, resulting in limited dust blocking. Therefore, in order to improve the dust blocking effect, the difference between this embodiment and the first embodiment is that please refer to Figure 8-Figure 9 shown, where:

[0049] The bottom of the blocking cover 2 is provided with two symmetrical bottom plates 21, and the edge of the bottom plate 21 is movably connected with the bottom of the blocking cover 2. When the blocking cover 2 blocks the dust, the two bottom plates 21 can be rotated to the bottom of the blocking cover 2, and the open block can be blocked. The bottom of the cover 2 is blocked to reduce the dust scattering effect and improve the dust removal effect.

[0050] Specifically, the outer wall of the fixed box 1 near the bottom is provided with two linkage racks 17 , the inner wall of the blocking cover 2 is rotated with a connecting rod 22 , and one end ...

Embodiment 3

[0053] Considering the dust sucked into the dust collector box 3, when the air pump 310 stops working, it is easy to fall from the inner cavity of the dust collector box 3 into the fixed box 1 again. Therefore, in order to improve the dust storage effect, this embodiment and the first embodiment The difference is, see Figure 10 shown, where:

[0054] A cavity 31 and a storage cavity 32 are provided inside the dust suction box 3. The storage cavity 32 is located above the cavity 31. The air pump 310 is fixed inside the cavity 31. The storage cavity 32 can suck the dust inside the fixed box 1 into the storage cavity 32 from the dust inlet end when the air pump 310 is working. The dust can only be entered from the dust inlet end of the air pump and discharged from the dust discharge end, so as to avoid a large dust inlet space. , causing the dust to flow in the opposite direction and improve the dust storage effect.

[0055] In order to facilitate the installation and disassem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com