Green iron tailing concrete with high carbonization resistance and preparation method thereof

A technology for concrete and iron tailings, applied in the directions of climate sustainability, sustainable waste treatment, solid waste management, etc. The effect of improved carbonization resistance, high economic value, and improved compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]The high carbonation resistance green iron tailings concrete described in this embodiment, the raw materials for each cubic meter of concrete include: cement 290kg, iron tailing powder 124kg, iron tailing sand 785kg, iron tailing ore 1084kg, water reducer 2.07kg, water 170kg . Among the above-mentioned raw materials, cement and iron tailings powder as admixtures form a gel material (total 414kg), and each raw material is fully mixed and stirred to obtain the desired concrete.

[0034] After testing, the strength grade of the concrete is C30, and the replacement ratio of iron tailings powder to cement is 30%.

Embodiment 2

[0036] The green iron tailings concrete with high carbonation resistance described in this example, the raw materials for each cubic meter of concrete include: cement 361kg, iron tailing powder 155kg, iron tailing sand 746kg, iron tailing ore 1030kg, water reducing agent 2.58kg, water 170kg . Among the above-mentioned raw materials, cement and iron tailings powder as admixtures form a gel material (total 516kg), and each raw material is fully mixed and stirred to obtain the desired concrete.

[0037] After testing, the strength grade of the concrete is C40, and the replacement ratio of iron tailings powder to cement is 30%.

experiment example

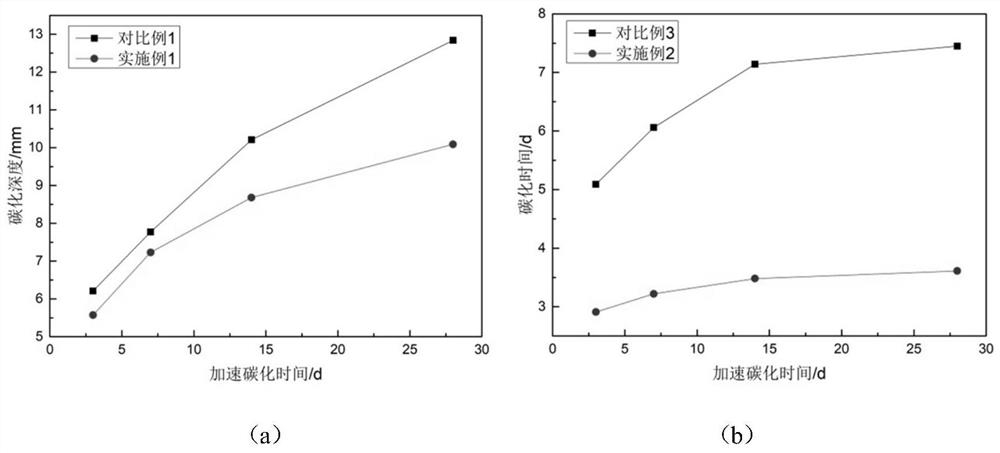

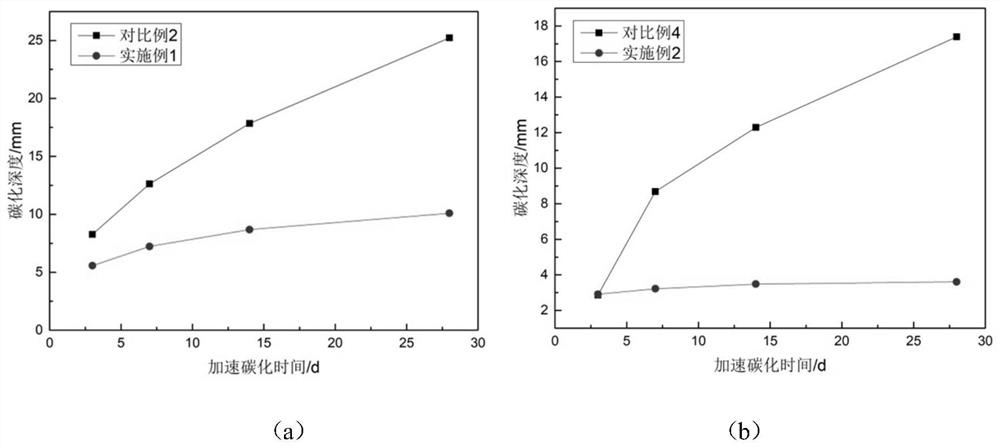

[0047] According to the rapid carbonation test regulations in GB / T 50082-2009 "Standards for Long-term Performance and Durability of Ordinary Concrete", the concrete prepared according to the plans of Example 1-2 and Comparative Example 1-4 was made into several 100mm×100mm× 400mm prismatic test block, after standard curing for 28d in an environment with a relative temperature of 20±2°C and a relative humidity of not less than 95%, it is continuously dried for 48h in a constant temperature drying oven at 60°C, and then the surface of the test block is smeared with paraffin and placed in Rapid carbonization box, the temperature in the carbonization box is 20±2℃, the relative humidity is 70±5℃, CO 2 The concentration is 20±3%; after the specified age (3d, 7d, 14d, 28d), the test block is taken out, and its carbonization depth is measured. The test results are as follows in Table 1 and attached. Figure 1-2 shown.

[0048] Table 1 Carbonization test results

[0049]

[0050...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com