Room-temperature self-repairing flexible organic silicon thermal interface material with self-adhesion characteristic and preparation method of room-temperature self-repairing flexible organic silicon thermal interface material

A thermal interface material, silicone technology, applied in the direction of climate sustainability, sustainable manufacturing/processing, chemical industry, etc., can solve the problems of low self-healing efficiency, no self-adhesive performance, no self-healing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

Specific implementation method one

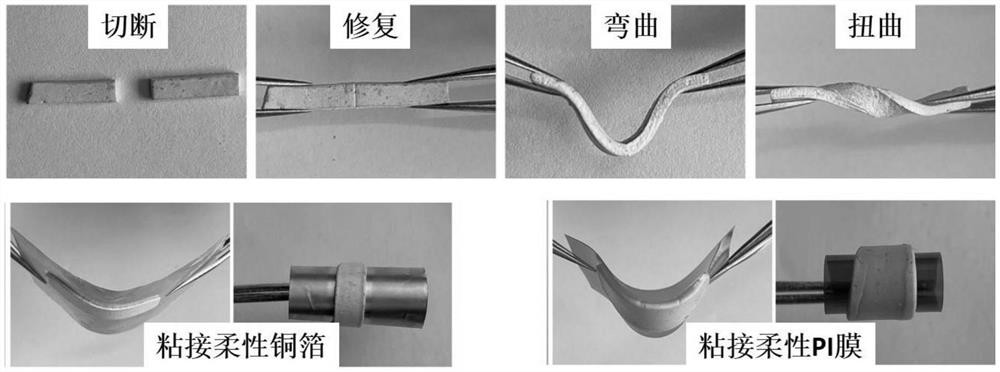

[0034]A room temperature with self -adhesion characteristics self -repairing flexible organic silicon thermal interface material, which is self -restored by the room temperature to stretch the flexible silicon thermal interface material from the room temperature self -repairing the silicon polymer and the hydroxyl function, boron nitride, silicane amino group Functional silicon nano -wire thermal conductivity is obtained through in -situ aggregation and solvent assisted assembly.

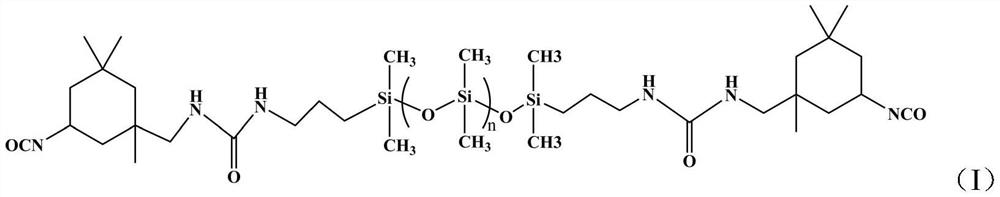

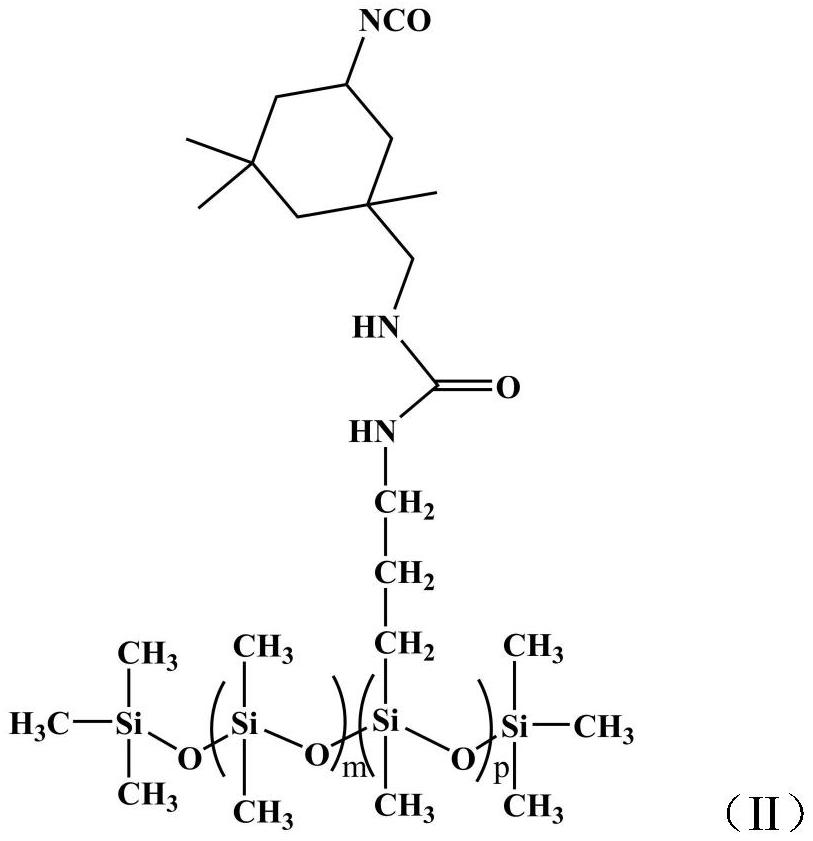

[0035] Further, the self -adhesive room temperature self -repairing flexible organic silicon polymer is based on the co -agglomeration between functional flexible organic silicon molecules. The aggregation between the functional silicon molecule of the group and the functional silicon molecule of the hydroxyl group of the hydroxyl -based group. The isocyanate group is an isoporraxylisate group. There are two types of the functional silicon molecules of isocyanate: one...

specific Embodiment approach 2

[0036] Further, the quality ratio of the quality ratio of a hydroxyl function nitrogen nitrogen nitrogen nitrogen and sirrotamidamine -based functionalized silicon nano -wire heating fillers and room temperature self -repairing organic silicon polymers is 30 to 50: 100. The mass ratio of boronized and silate functionalized silicon carbonized nano -noodles is 100: 25 ~ 50. The boron -sitrosis of hydroxyl function is a sheet layer structure with a thickness of 2 to 20nm. The size is 2 to 5 μm, and the length of the silicane amino -based silicon nano -nano is 10-50 μm.

Specific implementation method 2

[0038] A preparation method of self -adhesion characteristics self -repairing flexible organic silicon thermal interface materials, including the following steps:

[0039] Step 1. The synthesis of hydroxyl function nitrogen nitrogen nitride

[0040] (1) Mix the exfoliating water and water-free ethanol at a ratio of 1: 1-4.5 to obtain a mixed solution A evenly, and add the boron nitri...

Embodiment 1

[0046] Add functional silicon molecules Ⅰ and II, III, and IV to 1.05 ~ 1.1: 1 in an Murbi of the alcohol group and the hydroxyl group of the hydroxyl group. Stir at room temperature 1.5 to 3h to form a uniform solution D, add the total mass of the total silicon polymer to the solution D with a total mass of 30 to 50 % of the heat conductive fillers. After the ultrasonic dispersion is 30 to 60min, under the condition of nitrogen or inert gas protection and magnetic mixing conditions, 40 The reaction is 3 to 6h at 60 ° C, then open the reactor mouth, and continue to stir under 40-50 ° C to volatilize the chloroform or water -free dichloromethane until the volume of the solution becomes the original 1 / 2 to 1 / 3. After the solution is cooled to 25-30 ° C, pour it into the mold of polytetrafluoroethylene, and place the vector cabinet to continue to volatilize the remaining chloroform or water -free dichloropenhane. The room temperature is self -repairing flexible organic silicon therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Sheet size | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com