Self-early-warning coaxial electrostatic spinning fiber as well as preparation method and application thereof

A coaxial electrospinning and electrospinning technology, which is applied in electrospinning, fiber treatment, fiber chemical characteristics, etc., can solve problems such as damage to comprehensive performance, material catastrophic damage, shortened service life, etc., and achieve broad application prospects , Improve the fracture strength, improve the effect of mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention further provides a method for preparing self-warning coaxial electrospinning fibers, and the specific implementation steps are as follows:

1) Preparation of A component coaxial shell solution: The polymer 1, the polymer 2, the solvent 1, and the solvent 2 are prepared according to the mass ratio of 0.2-1:0.5-5:9-15:9-15, The order of addition of the drugs is as follows:

1.1) Polymer 1 and solvent 1 are mixed first, and stirred at a speed of 200-8000 rmp for 12-24 hours within a temperature range of 20-35 °C;

1.2) Mix the polymer 2 with the solvent 2, and stir at a speed of 300-800rmp for 14-36 hours within the temperature range of 50-100°C;

1.3) Mix the above two solutions in a ratio of 6:1-4, and stir at 20-35°C for 2-10 hours;

2) Preparation of B-component coaxial core solution: Weigh the indicator and solvent according to the mass ratio of 1:5-20, and stir at a speed of 200-8000rmp for 2-10 hours within the temperature range of 20-25°C. ;...

Embodiment 1

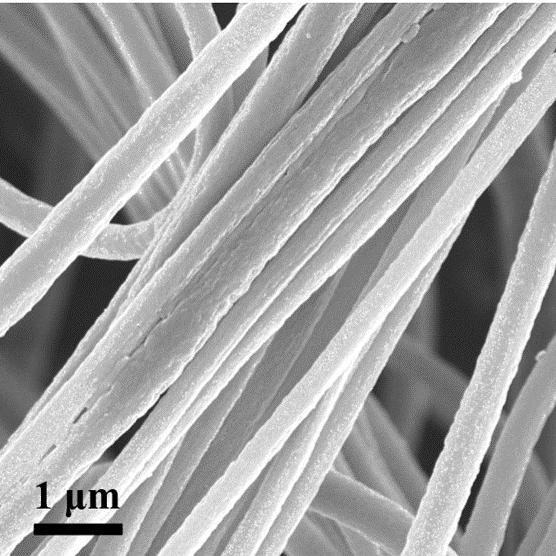

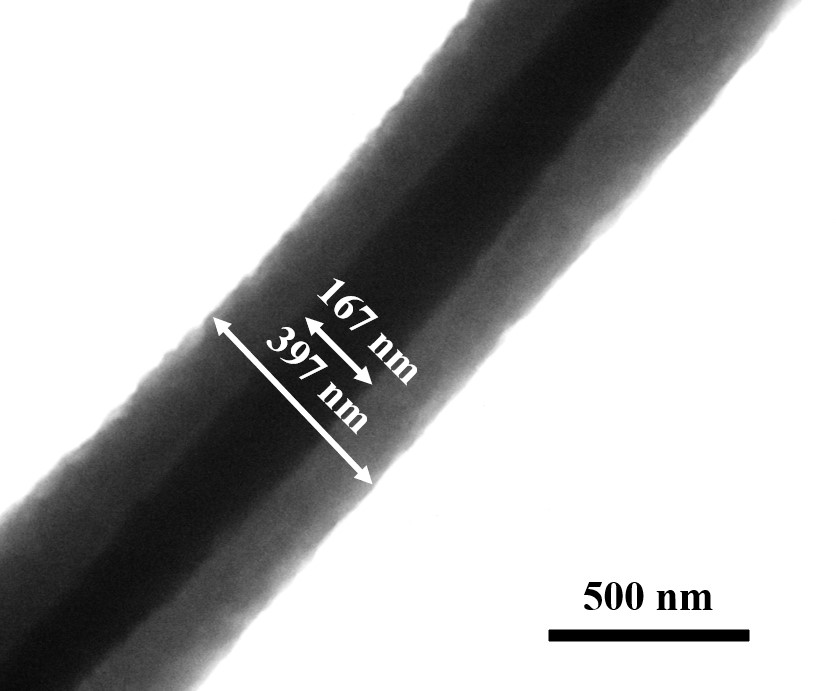

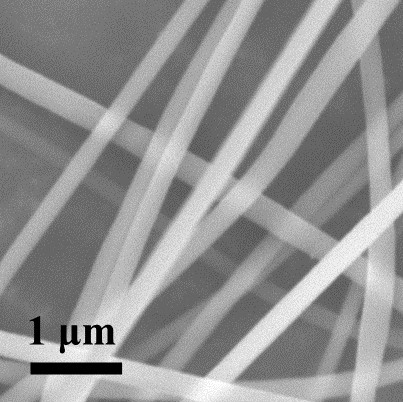

A self-warning coaxial electrospinning fiber provided by the present invention comprises a component A shell structure and a component B core structure loaded inside the shell structure,

Specific steps are as follows:

1) Preparation of the coaxial shell solution of component A: The polymer 1, polymer 2, solvent 1 and solvent 2 are prepared according to the mass ratio of 0.3:1:15:10. The order of adding the drugs is as follows:

1.1) Dissolve 3g of chitin (CS) in 150mL of 2% acetic acid aqueous solution and stir magnetically for 14 hours until uniformly dissolved;

1.2) Dissolve 1 g of polyvinyl alcohol (PVA) in 10 mL of deionized water, heat it in a 95°C water bath, and stir magnetically for 16 hours until it is completely dissolved;

1.3) Mix the above two solutions in a ratio of 6:4, and stir at 25°C for 3 hours;

2) Preparation of the B-component coaxial core solution: add 1 g of phenanthroline (Phen) to 10 mL of deionized water, and stir for 5 hours at a temperature of ...

Embodiment 2

A self-warning coaxial electrospinning fiber provided by the present invention comprises a component A shell structure and a component B core structure loaded inside the shell structure,

Specific steps are as follows:

1) Preparation of the coaxial shell solution of component A: The polymer 1, polymer 2, solvent 1, and solvent 2 are prepared according to the mass ratio of 0.3:1:15:10. The order of adding the drugs is as follows:

1.1) Dissolve 3g of chitin (CS) in 150mL of 2% acetic acid aqueous solution and stir magnetically for 14 hours until uniformly dissolved;

1.2) Dissolve 1 g of methylcellulose (MC) in 10 mL of deionized water, heat it in a water bath at 80°C, and stir magnetically for 16 hours until it is completely dissolved;

1.3) Mix the above two solutions in a ratio of 6:2 and stir at 25°C for 5 hours;

2) Preparation of the B-component coaxial core solution: add 1 g of phenanthroline (Phen) to 10 mL of deionized water, and stir for 5 hours at a temperature of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com