Glass fiber automatic detection system and method

A glass fiber, automatic detection technology, applied in measuring devices, by removing certain components, weighing, material weighing, etc., can solve the problem of manual weighing data error-prone efficiency, low efficiency and accuracy, and high manual work intensity. and other problems, to achieve the effect of providing detection efficiency, saving labor costs, and reducing accidental injury rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

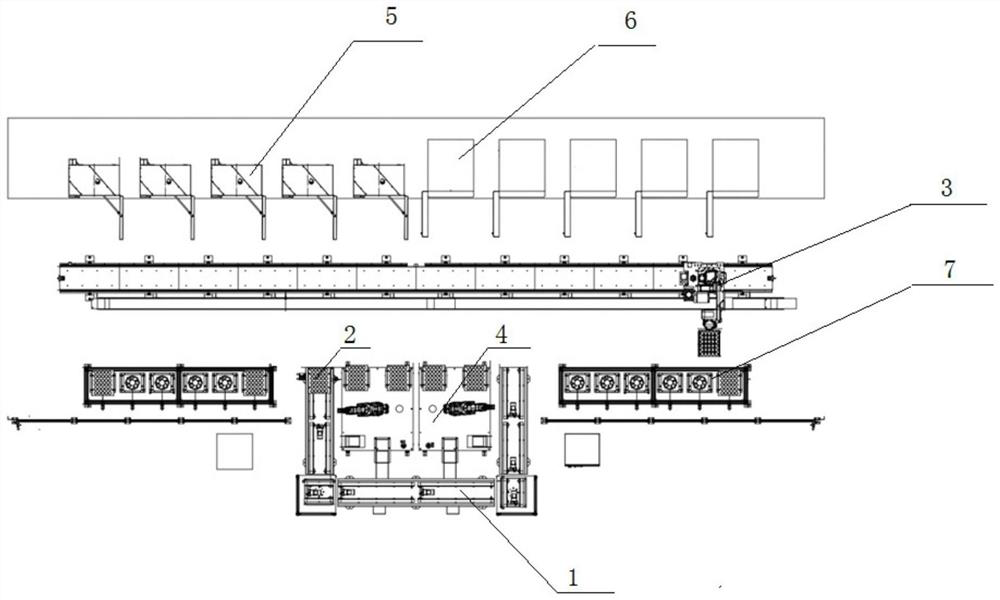

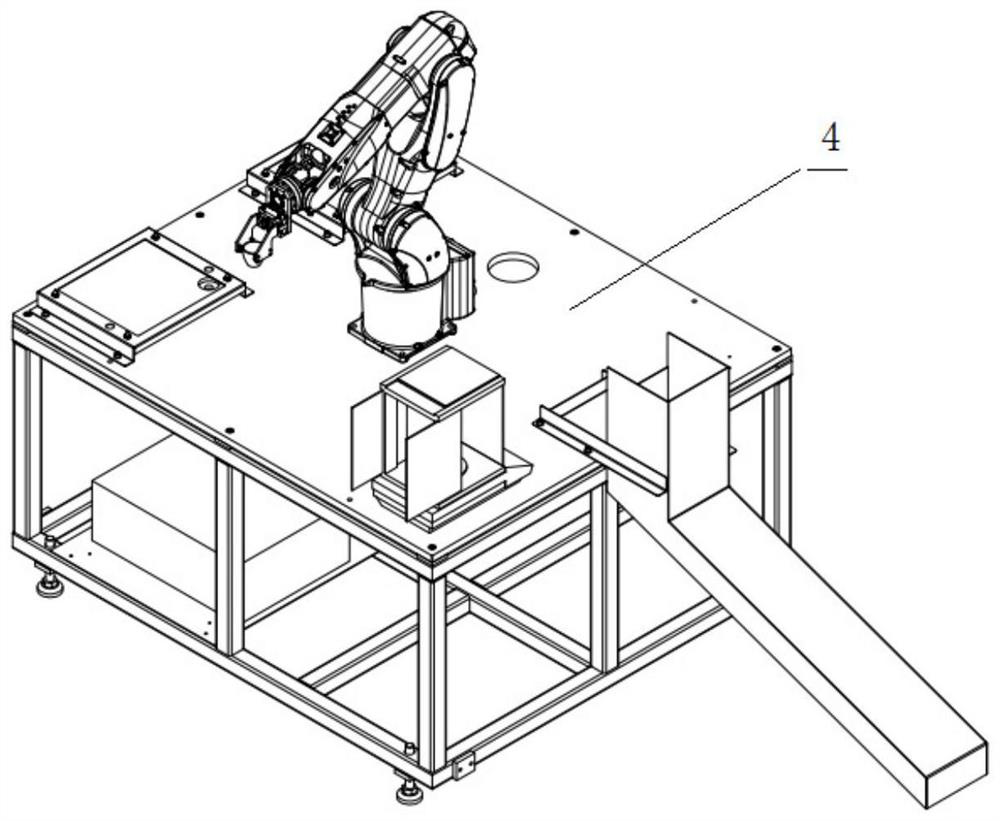

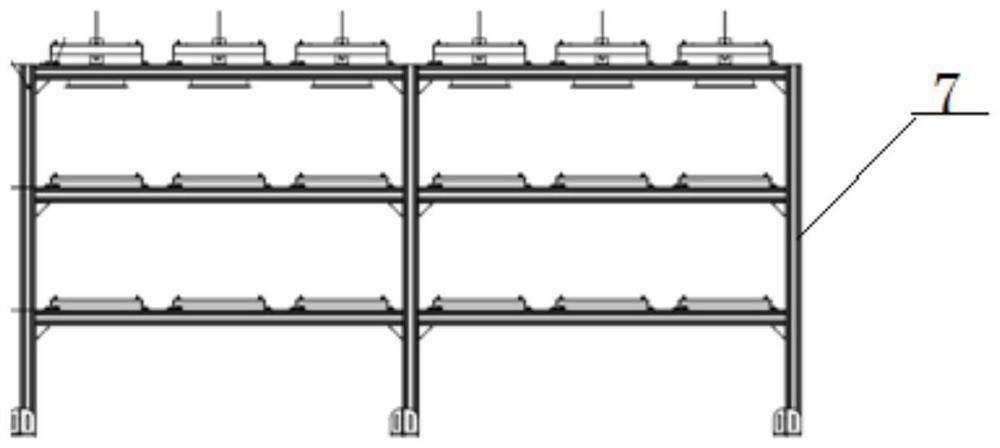

[0050] like figure 1 As shown, this embodiment provides an automatic glass fiber detection system, including a crucible rack conveying line 1, a transfer device 3, a weighing device 4, a drying device 5, a combustion device 6, a cooling device 7 and a control system; the control system The system is connected with the crucible rack conveying line 1, the transfer equipment 3 and the weighing equipment 4 respectively.

[0051] In a specific implementation process, the crucible rack conveying line 1 is used to transport the crucible rack 2 to a set position, and the crucible rack 2 carries the glass fiber sample.

[0052] Wherein, the crucible rack conveying line 1 is a U-shaped conveying line or an L-shaped with two upper and lower layers.

[0053] like Figure 4 As shown, the crucible rack conveying line 1 includes a transmission motor and a supporting transmission mechanism, a belt, a segmented conveying line body and a rotating docking mechanism. Sectional belt conveying d...

Embodiment 2

[0078] This embodiment provides an automatic glass fiber detection system, which includes a crucible rack conveying line, transfer equipment, weighing equipment, drying equipment, combustion equipment, cooling equipment and a control system; The equipment and the weighing equipment are connected separately;

[0079] The crucible rack conveying line is used to transport the crucible rack to the set position, and the crucible rack carries the glass fiber sample; the transfer device is used to: transfer the crucible rack in the set position to the weighing device for the first weighing , send the crucible rack after the first weighing to the drying equipment for drying, transfer the dried crucible rack to the cooling equipment for the first cooling, and transfer the crucible rack after the first cooling to the weighing equipment for For the second weighing, send the crucible rack after the second weighing to the burning equipment for burning, and then send the burning crucible ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com