Ultraviolet Micro-LED based on LSPs coupling enhancement

A substrate, p-type technology, applied in the fields of nanotechnology, instruments, nanotechnology, etc. for materials and surface science, can solve problems such as the inability to meet device applications and the inability to improve the quantum efficiency of ultraviolet LEDs. Achieve high internal quantum efficiency and improve luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

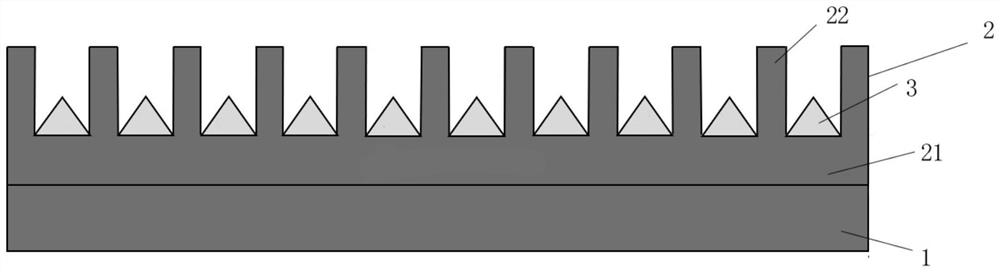

[0034] This embodiment provides an enhanced UV Micro-LED based on Localized Surface Plasmons (LSPs) coupling, refer to figure 1 , including an active region 1 , a p-type AlGaN layer 2 and a metal nanoparticle structure 3 . The active region 1 is disposed under the p-type AlGaN layer 2 ; the p-type AlGaN layer 2 includes a substrate 21 and a plurality of gate pillars 22 , and the gate pillars 22 are arranged on the substrate 21 at equal distances, and between adjacent gate pillars 22 A grating groove is formed; the metal nanoparticle structure 3 is arranged in the grating groove.

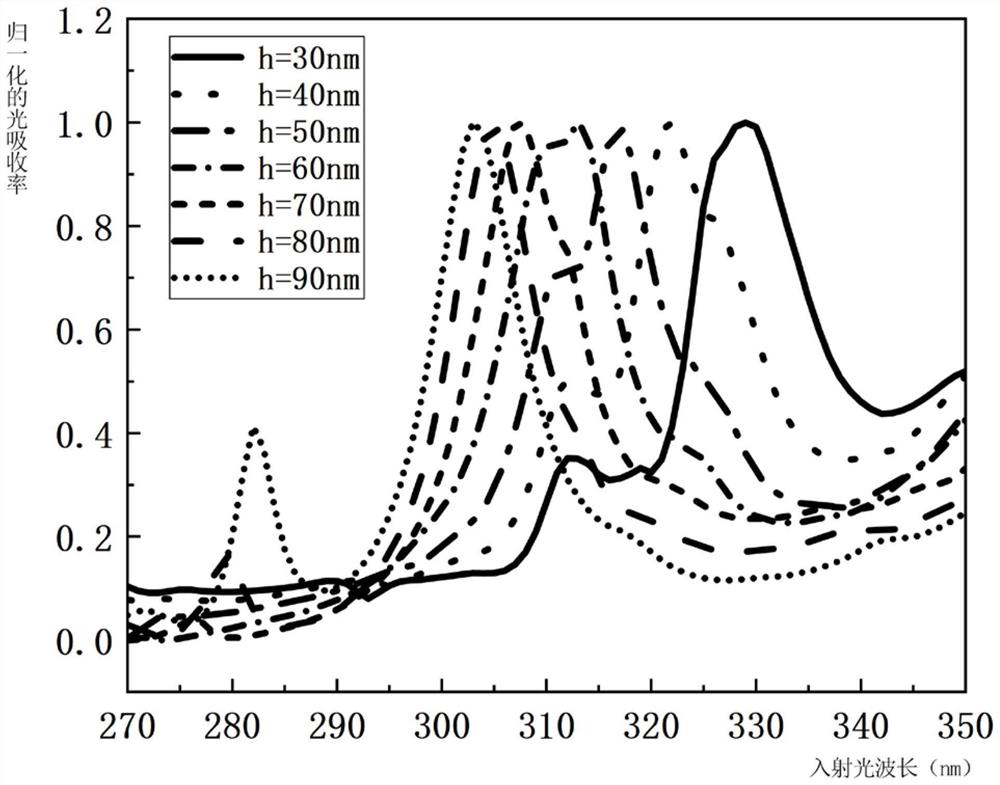

[0035] In application, the height of the metal nanoparticle structure is 50nm-90nm, and at this time, the relative value of electric field strength enhancement near the active region is the largest, which is 1.7.

[0036] By adjusting the height of the metal nanoparticle structure, the invention makes the plasmon resonance wavelength shift to the ultraviolet band to realize the resonance coupling wi...

Embodiment 2

[0038] On the basis of Embodiment 1, the refractive index of the p-type AlGaN layer 2 of the UV Micro-LED based on enhanced LSPs coupling provided in this embodiment is 2.5, and the p-type AlGaN layer 2 is set to a periodic grating structure. The periodic grating The period length of the structure is 300 nm.

[0039] In addition, the height of the p-type AlGaN layer 2 is 55 nm, the height of the base material is 15 nm, and the height of the gate pillar is 40 nm. The groove depth of each grating groove is 40 nm, and the sum of the bottom area of each grating groove is equal to the sum of the bottom area of each grating column. The bottom surface of the active region 1 is set to be square, and the size of the square is 3 μm×3 μm.

[0040] In application, the material of the metal nanoparticles 3 is aluminum. The local plasmon resonance frequencies of silver and gold are generally located in the visible light region, while the local plasmon resonance frequency of aluminum i...

Embodiment 3

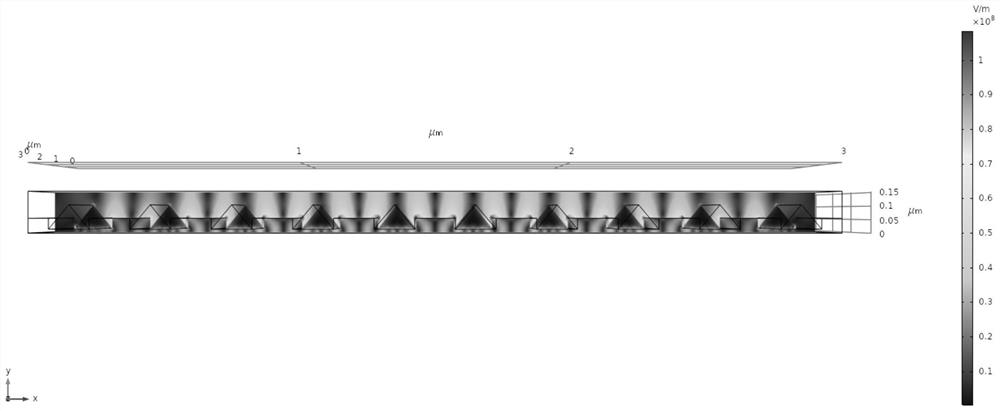

[0044] On the basis of Embodiment 1 or 2, the luminous efficiency of the UV Micro-LED based on LSPs coupling enhancement provided in this embodiment is related to Internal Quantum Efficiency (IQE) and light extraction efficiency, wherein the light extraction efficiency is related to the luminescent material. related to the external structure. According to Fermi's golden rule, due to the strong electric field generated by the coupling of localized surface plasmons (LSPs) and the active region, the electric field strength is enhanced, thereby increasing the rate of energy coupling of localized surface plasmons, which in turn increases the The internal quantum efficiency of UV Micro-LEDs is calculated, and the specific reference is made to formulas (1)-(2):

[0045]

[0046]

[0047] Among them, IQE is the internal quantum efficiency of UV Micro-LED based on LSPs coupling enhancement, k lsp is the rate of energy coupling into the surface plasmon, k rad is the radiative re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Cycle length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com