Fresh milk-grade humanized cow milk protein base material and preparation method thereof

A technology of milk protein and fresh milk, which is applied in the direction of dairy products, milk preparations, and other dairy products, can solve the problems of difficult industrial production and high operating costs, and achieve the effects of localization, good quality, and reduced dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

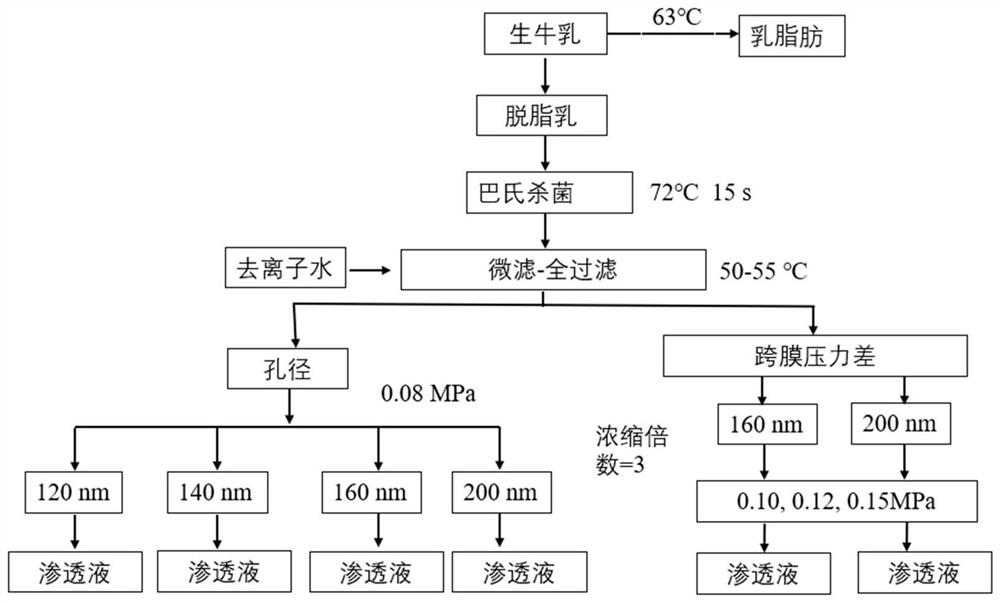

[0039]This embodiment provides a method for preparing a fresh milk-grade breast milk protein base material, and the process flow diagram of the exploration process in Example 1 is shown in figure 1 , the steps of the research process are as follows:

[0040] (1) Sterilization: Take 50L of raw milk, the mass percentage of dry matter of raw milk is 12.54%, the acidity is lower than 18°T, and the total number of bacteria is 4.8×10 4 pcs / mL; the heating temperature of the sterilizer is 72 °C, heating for 15s, the cooling temperature of the first stage is 65 °C, and the cooling temperature of the second stage is 55 °C.

[0041] (2) Centrifugal skim: 50L of raw milk, at a temperature of 55°C, a centrifugal rotation speed of 7000r / min, and a feed flow rate of 120L / h, carry out milk fat separation, which takes 30min to obtain 48kg of skim milk with a fat content of 0.08%.

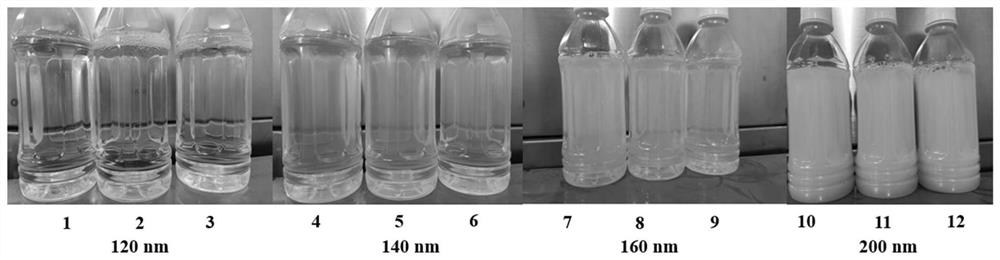

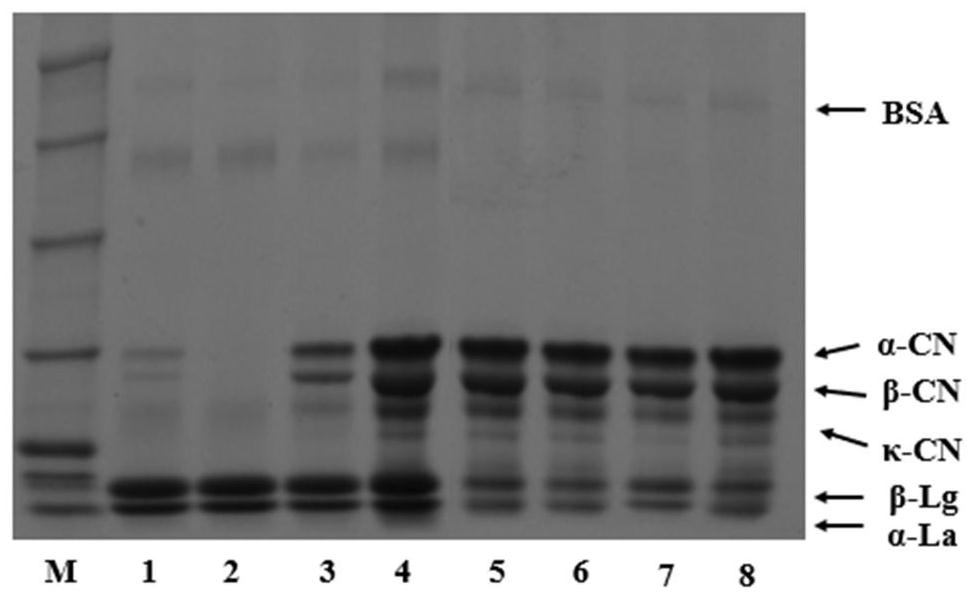

[0042] (3) Microfiltration and full filtration: all the obtained skim milk is put into the microfiltration equi...

experiment example 1

[0080] Experimental Example 1 Energy consumption detection

[0081] The energy consumption test results show that in the scheme of directly preparing permeate casein and whey protein 1:1 (Example 1), using a larger membrane pore size, the protein mass transfer rate will be faster, and the average membrane flux throughout the process will be 128kg / m 2 h, compared to the membrane flux of Comparative Example 1 (66kg / m 2 h) Nearly twice as high, the separation speed is faster, thus saving separation time and energy consumption.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com