Silicon material, preparation method and application thereof, and device using silicon material

A silicon material and silicon source technology, applied in the field of materials, can solve the problem of further improvement of charge-discharge specific capacity and cycle stability, achieve excellent cycle stability, achieve large-scale production, and improve self-stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

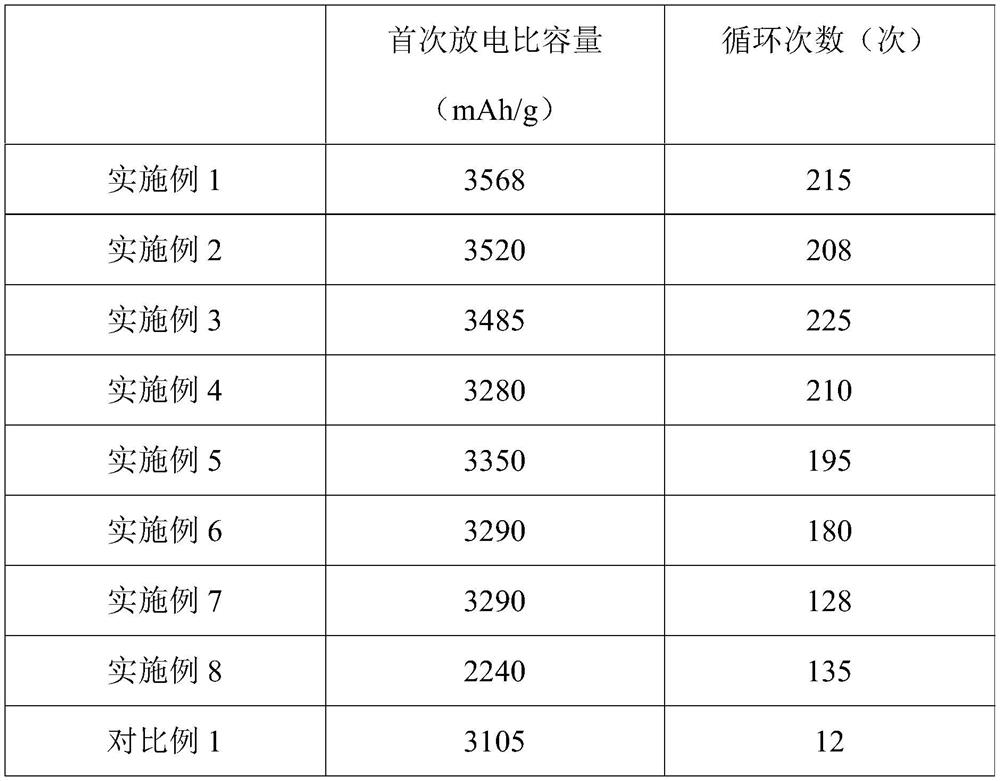

Examples

Embodiment 1

[0056] Preparation of flower cluster structure silicon material:

[0057] The crystalline silicon particles (1-5 μm) and metal lithium mixed in a 1:1 weight ratio under an argon atmosphere were heated to 300 °C, kept for 1 h, and then heated to 650 °C under a low pressure (90 kPa) argon atmosphere. After keeping the temperature for 2 hours, the cooled product was washed with ethanol and water to remove lithium-containing by-products to obtain a flower cluster structure silicon material.

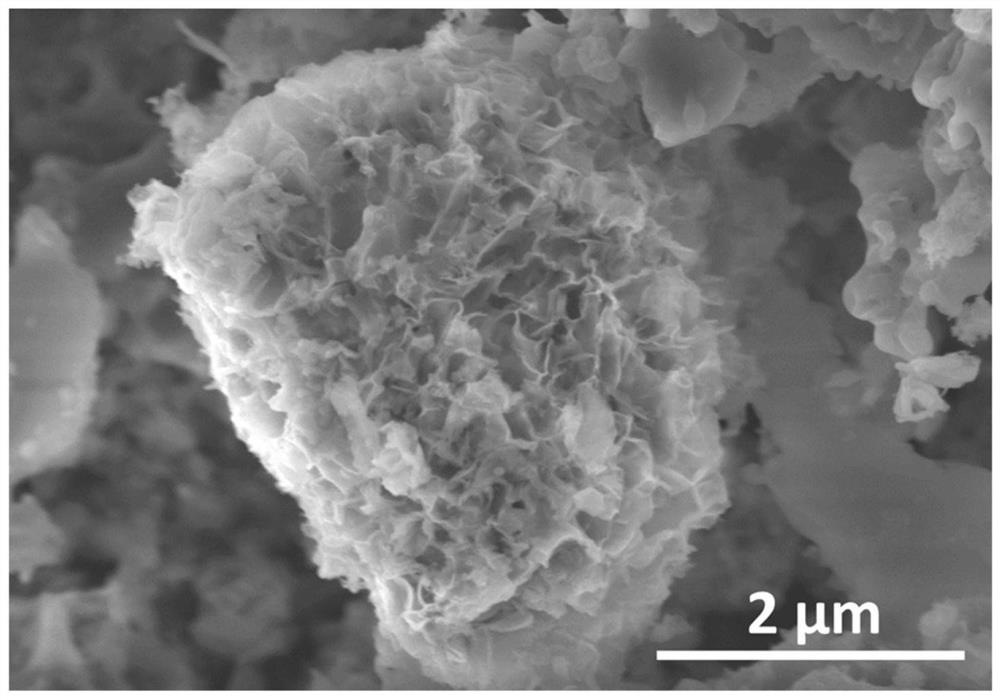

[0058] figure 1 The scanning electron microscope image of the silicon material prepared in this example shows that the flower-like silicon microparticles are composed of interconnected wavy two-dimensional silicon nanosheets, and have a flower-like structure.

[0059] The silicon material prepared in this example includes flower-like silicon microparticles composed of wavy silicon nanosheets connected to each other, the flower-like silicon microparticles have a particle size of 1-6 μm, and t...

Embodiment 2

[0065] Preparation of flower cluster structure silicon material:

[0066] In an argon atmosphere, the crystalline silicon particles (5-10 μm) and metal lithium mixed in a weight ratio of 3:2 were heated to 250 °C and kept for 2 h, and then heated to 700 °C under a low pressure (80 kPa) nitrogen atmosphere, and then kept for 1 h. , the cooled product is washed with ethylene glycol and water to remove lithium-containing by-products (such as lithium nitride) to obtain a flower cluster structure silicon material.

[0067] The silicon material prepared in this example includes flower-like silicon micro-particles formed by interconnecting wavy silicon nanosheets. The flower-like silicon micro-particles have a particle size of 8-15 μm, and the 10-20nm.

[0068] Prepare the negative electrode:

[0069] Using the flower cluster structure silicon material of this embodiment as the negative electrode active material, the negative electrode active material, the binder polyacrylic acid (...

Embodiment 3

[0073] Preparation of flower cluster structure silicon material:

[0074] In an argon atmosphere, the crystalline silicon particles (5-10 μm) and metal lithium mixed in a weight ratio of 6:5 were heated to 400 °C and kept for 30 min, and then heated to 600 °C under a low pressure (50 kPa) helium atmosphere, and then kept at a temperature of 600 °C. 4h, the cooled product was washed with isopropanol and water to remove lithium-containing by-products to obtain a flower cluster structure silicon material.

[0075] The silicon material prepared in this example includes flower-like silicon micro-particles formed by interconnecting wavy silicon nanosheets. The flower-like silicon micro-particles have a particle size of 8-15 μm, and the 20-30nm.

[0076] Prepare the negative electrode:

[0077] Using the flower cluster structure silicon material of this embodiment as the negative electrode active material, the negative electrode active material, the binder sodium alginate, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com