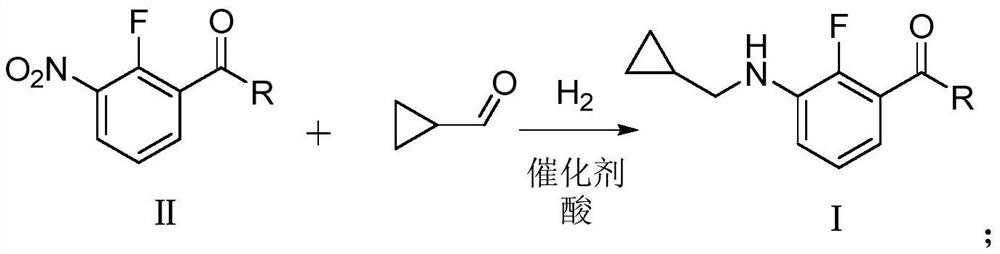

Preparation method of N-cyclopropyl methylaniline compound

A technology of cyclopropylmethylaniline and compounds, which is applied in the field of preparation of N-cyclopropylmethylaniline compounds, can solve the problems of a large amount of solid residue and post-processing difficulties, achieve less impurities, reduce post-processing operations, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

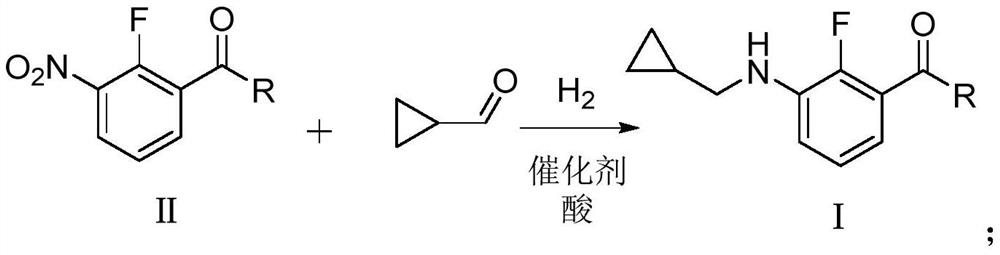

[0059] The present embodiment prepares 3-[(cyclopropylmethyl)amino]-2-fluorobenzoic acid methyl ester, and the reaction formula is as follows:

[0060]

[0061] Into the 500mL autoclave, 40.2g of 3-nitro-2-fluoro-methyl benzoate (0.2mol, 99% purity), 0.2g of 5% platinum carbon catalyst, 7.96g of acetic acid (0.13mol, 99% purity), Cyclopropylcarbaldehyde 16.8g (0.24mol, purity 99%) and methanol 119.4g were hydrogenated to a pressure of 1.0MPa and reacted at 40°C for 12h. After the reaction, filter, wash the filter residue with 20g methanol, combine the filtrates to remove the solvent under reduced pressure, and dry to obtain 43.2g of methyl 3-[(cyclopropylmethyl)amino]-2-fluorobenzoate, content 98.5% (external standard method, the same below), the yield was 95.4% (mass yield, the same below).

[0062] The characterization data is as follows:

[0063] LC / MS [M+1]: m / z=224.

[0064] 1 H NMR (400MHz, CDCl3) data as follows (δ[ppm]): 7.18-7.15 (m, 1H), 7.05-7.01 (m, 1H), 6.8...

Embodiment 2

[0066] The present embodiment prepares 3-[(cyclopropylmethyl)amino]-2-fluorobenzoic acid ethyl ester, and the reaction formula is as follows:

[0067]

[0068] In the 500mL autoclave, 43.0g of 3-nitro-2-fluoro-ethyl benzoate (0.2mol, 99% purity), 0.42g of 5% platinum carbon catalyst, 8.52g of acetic acid (0.14mol, 99% purity), Cyclopropylcarbaldehyde 19.6g (0.28mol, purity 99%) and ethanol 213g were hydrogenated to a pressure of 2.0MPa and reacted at 60°C for 14h. After the reaction, filter, wash the filter residue with 20g ethanol, combine the filtrates to remove the solvent under reduced pressure, and dry to obtain 3-[(cyclopropylmethyl)amino]-2-fluorobenzoic acid ethyl ester 45.1g, content 98.0%, yield was 93.2%.

[0069] Characterization data:

[0070] LC / MS [M+1]: m / z=238.

Embodiment 3

[0072] The present embodiment prepares 3-[(cyclopropylmethyl)amino]-2-fluorobenzoic acid propyl ester, and the reaction formula is as follows:

[0073]

[0074] In the 500mL autoclave, 45.9g of 3-nitro-2-fluoro-propyl benzoate (0.2mol, 99% purity), 0.91g of 5% platinum carbon catalyst, 18.16g of acetic acid (0.30mol, 99% purity), Cyclopropylcarbaldehyde 22.4 g (0.32 mol, purity 99%) and ethyl acetate 136.2 g were hydrogenated to a pressure of 3.0 MPa, and reacted at 100° C. for 16 h. After the reaction was completed, filter, wash the filter residue with 20 g of ethyl acetate, combine the filtrates to remove the solvent under reduced pressure, and dry to obtain 48.5 g of 3-[(cyclopropylmethyl)amino]-2-fluorobenzoic acid propyl ester with a content of 97.5%, The yield was 94.2%.

[0075] Characterization data:

[0076] LC / MS [M+1]: m / z=252.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com