A kind of treatment method of heavy metal sewage

A treatment method and heavy metal technology, applied in water/sewage treatment, water/sewage multi-stage treatment, oxidized water/sewage treatment, etc., can solve the problems of a large amount of chemical sludge, dosing a large amount of chemical agents, etc., and achieve high treatment efficiency , to eliminate secondary pollution, the effect of high operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

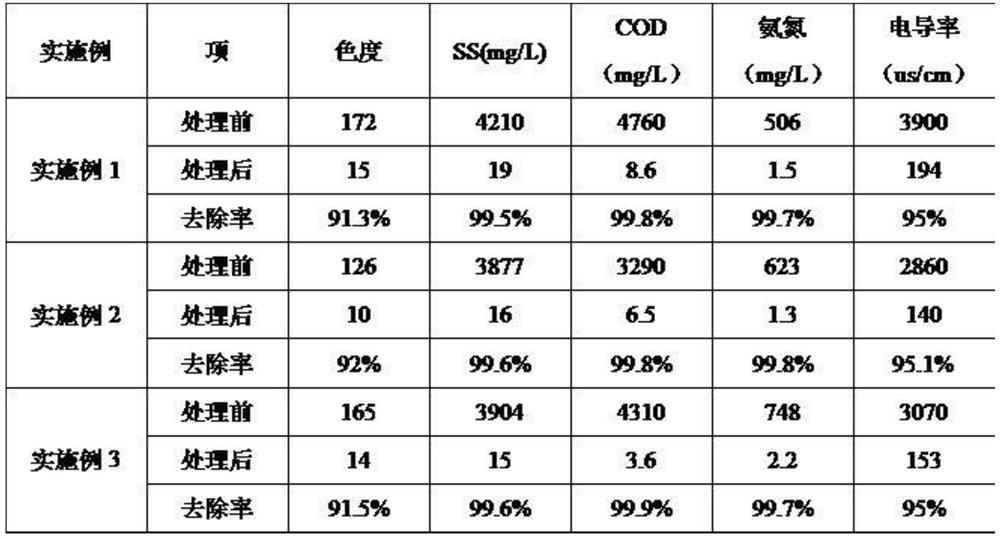

Embodiment 1

[0027] A treatment method for heavy metal sewage, the method comprises the following steps:

[0028] Step 1. Mechanical treatment: Sorting the sewage through the coarse mechanical grid, and then crushing the impurities through the fine mechanical grid, and then entering the cyclone grit chamber for treatment;

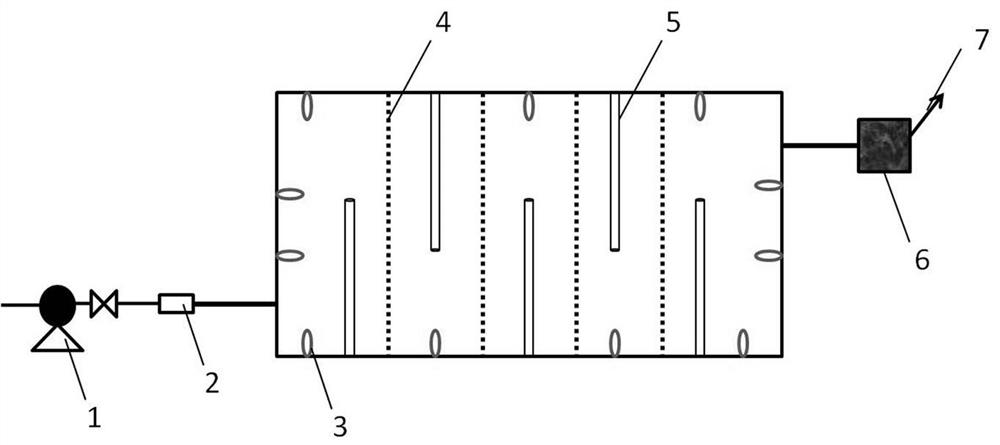

[0029] Step 2. Ultrasonic-microwave photocatalytic degradation of organic matter: the effluent of the cyclone grit chamber is passed through the reflux pump ( figure 1 Middle 1) into the ultrasonic-microwave photocatalytic reactor ( figure 1 shown), rod-shaped microwave electrodeless UV lamp ( figure 1 5) and nano Ag / TiO 2 Laser-melted electrospun porous silica fiber webs ( figure 1 Middle 4) Arranged in a staggered manner inside the reactor, turn on the microwave electrodeless ultraviolet lamp and the ultrasonic generator ( figure 1 Middle 3), reacted for 20min, the organic matter was degraded to generate volatile gas, which was passed through the tail gas treatmen...

Embodiment 2

[0034] A treatment method for heavy metal sewage, the method comprises the following steps:

[0035] Step 1. Mechanical treatment: Sorting the sewage through the coarse mechanical grid, and then crushing the impurities through the fine mechanical grid, and then entering the cyclone grit chamber for treatment;

[0036] Step 2. Ultrasonic-microwave photocatalytic degradation of organic matter: the effluent of the cyclone grit chamber is passed through the reflux pump ( figure 1 Middle 1) into the ultrasonic-microwave photocatalytic reactor ( figure 1 shown), rod-shaped microwave electrodeless UV lamp ( figure 1 5) and nano Ag / TiO 2 Laser-melted electrospun porous silica fiber webs ( figure 1 Middle 4) Arranged in a staggered manner inside the reactor, turn on the microwave electrodeless ultraviolet lamp and the ultrasonic generator ( figure 1 Middle 3), reacted for 30min, the organic matter was degraded to generate volatile gas, which was passed through the tail gas treatmen...

Embodiment 3

[0041] A treatment method for heavy metal sewage, the method comprises the following steps:

[0042] Step 1. Mechanical treatment: Sorting the sewage through the coarse mechanical grid, and then crushing the impurities through the fine mechanical grid, and then entering the cyclone grit chamber for treatment;

[0043] Step 2. Ultrasonic-microwave photocatalytic degradation of organic matter: the effluent of the cyclone grit chamber is passed through the reflux pump ( figure 1 Middle 1) into the ultrasonic-microwave photocatalytic reactor ( figure 1 shown), rod-shaped microwave electrodeless UV lamp ( figure 1 5) and nano Ag / TiO 2 Laser-melted electrospun porous silica fiber webs ( figure 1 Middle 4) Arranged in a staggered manner inside the reactor, turn on the microwave electrodeless ultraviolet lamp and the ultrasonic generator ( figure 1 Middle 3), reacted for 40min, the organic matter was degraded to generate volatile gas, which was passed through the tail gas treatmen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com