Sulfide solid electrolyte and preparation method and application thereof

A solid electrolyte and sulfide technology, applied in solid electrolytes, non-aqueous electrolytes, halide silicon compounds, etc., can solve the problems of low conductivity and poor stability, and achieve excellent lithium ion conductivity and excellent air stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a sulfide solid state electrolyte, and the sulfide solid state electrolyte is prepared by the following method:

[0039] Will Li 2 S, SiS 2 , SiO 2 , Sb 2 S 5 , LiI was added to the roller mill at a molar ratio of 56:7:5:4:20, and zirconia balls were added at the same time. The mass ratio of balls and raw materials was 10:1. The precursor powder was obtained by mixing at 300rpm for 24h. After the mixing was completed, the product was sintered at 550 °C for 12 h under an argon atmosphere to obtain the final product Li 6.6 Si 0.6 Sb 0.4 S 4.5 O 0.5 I electrolyte, the electrochemical window of the electrolyte can reach 6V. The phase of the sulfide solid state electrolyte is a sulfite phase.

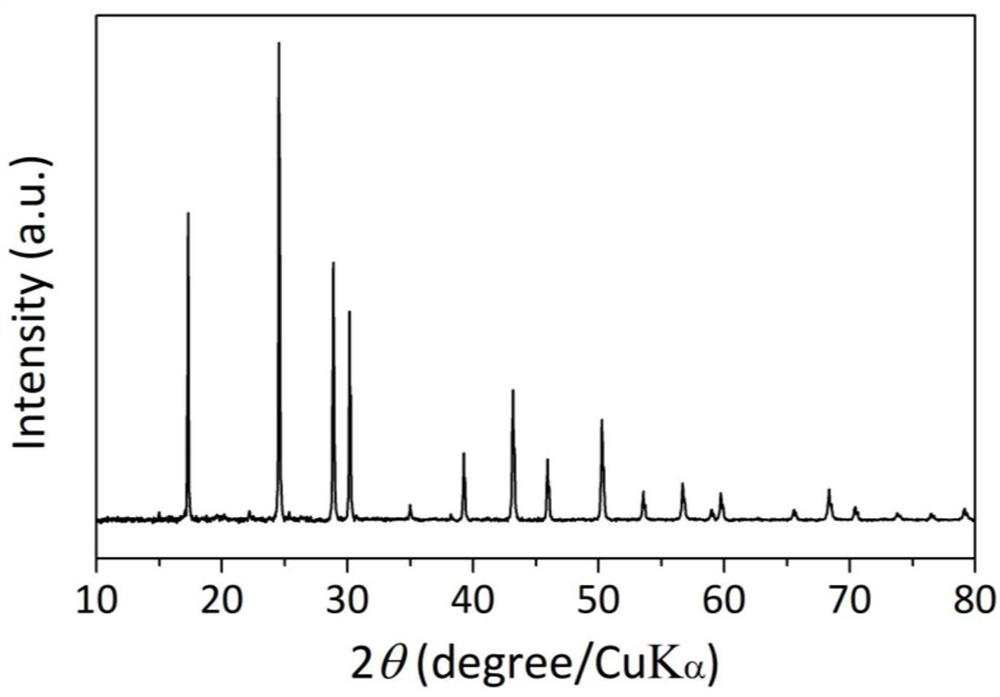

[0040] The X-ray diffraction spectrum of the sulfide solid electrolyte is as follows figure 1 shown.

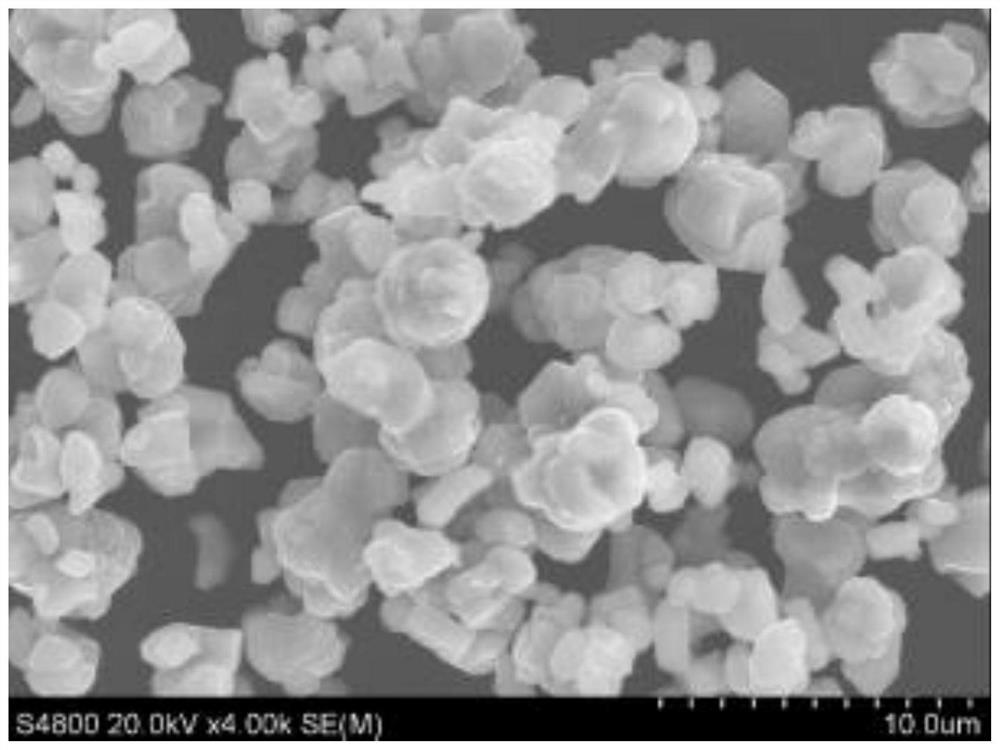

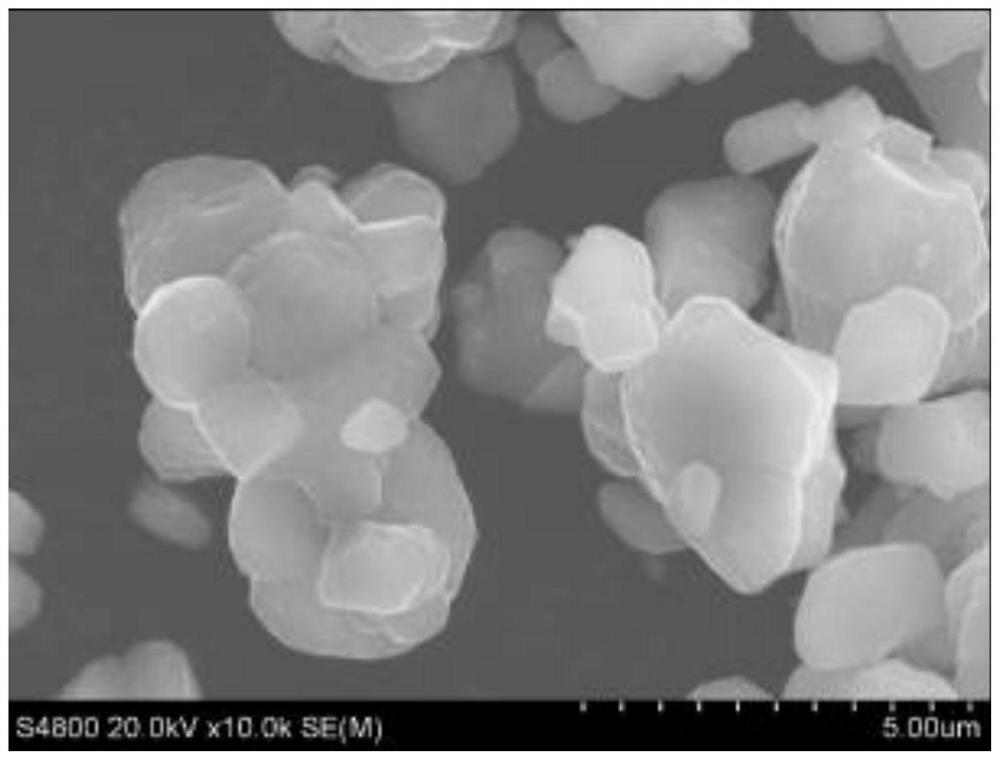

[0041] The SEM image of the sulfide solid electrolyte is as follows Figure 2-3 shown.

Embodiment 2

[0043] This embodiment provides a sulfide solid state electrolyte, and the sulfide solid state electrolyte is prepared by the following method:

[0044] Will Li 2 S, SiS 2 , SiO 2 , Sb 2 S 5, LiI was added to the high-energy ball mill at a molar ratio of 56:9:3:4:20, and zirconia balls were added at the same time. The mass ratio of balls to raw materials was 20:1. The precursor powder was obtained by mixing at 550rpm for 12h. The product was sintered at 450 °C for 6 h under vacuum to obtain the final product Li 6.6 Si 0.6 Sb 0.4 S 4.7 O 0.3 I electrolyte, the electrochemical window of the electrolyte can reach 5V. The phase of the sulfide solid state electrolyte is a sulfite phase.

Embodiment 3

[0046] This embodiment provides a sulfide solid state electrolyte, and the sulfide solid state electrolyte is prepared by the following method:

[0047] Will Li 2 S, SiS 2 , SiO 2 , Sb 2 S 5 , LiI was added to the mortar according to the molar ratio of 56:5:7:4:20, and the precursor powder was obtained by hand grinding and mixing for 4h. The product was sintered at 500 °C for 12 h under nitrogen atmosphere to obtain the final product Li 6.6 Si 0.6 Sb 0.4 S 4.3 O 0.7 I electrolyte. The phase of the sulfide solid state electrolyte is a sulfite phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Impedance | aaaaa | aaaaa |

| Impedance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com