High-temperature-resistant broadband wave-absorbing structure composite material and preparation method thereof

A composite material and high-temperature-resistant technology, which is applied in the field of microwave-absorbing materials, can solve problems such as structural strength to be improved, broadband microwave absorption cannot be guaranteed, and overall performance is poor, so as to achieve high repeatability and operability, improve application value, and overall sex-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A high-temperature-resistant broadband wave-absorbing structure composite material is composed of a composite material medium layer and a periodic structure layer which are sequentially compounded from outside to inside. The composite material medium layer is a fiber preform reinforced ceramic matrix composite material, from outside to inside. It is followed by a wave-transmitting layer and a loss layer, and the periodic structure layer is a metal composite material.

[0025] Further, the periodic structure layer is prepared on the lower surface of the composite material by etching and electroplating. Double effect of absorbing reflection, thickness 0.5mm, see figure 1 .

[0026] Further, the medium layer is a three-dimensional fabric reinforced ceramic matrix composite material, the wave-transmitting layer is quartz fiber, the loss layer is silicon carbide fiber, and the above-mentioned fibers of each layer form a three-dimensional overall structure by means of angula...

Embodiment 2

[0036]A high-temperature-resistant broadband wave-absorbing structure composite material is composed of a composite material medium layer and a periodic structure layer which are sequentially compounded from outside to inside. The composite material medium layer is a fiber preform reinforced ceramic matrix composite material, from outside to inside. It is followed by a wave-transmitting layer and a loss layer, and the periodic structure layer is a metal composite material.

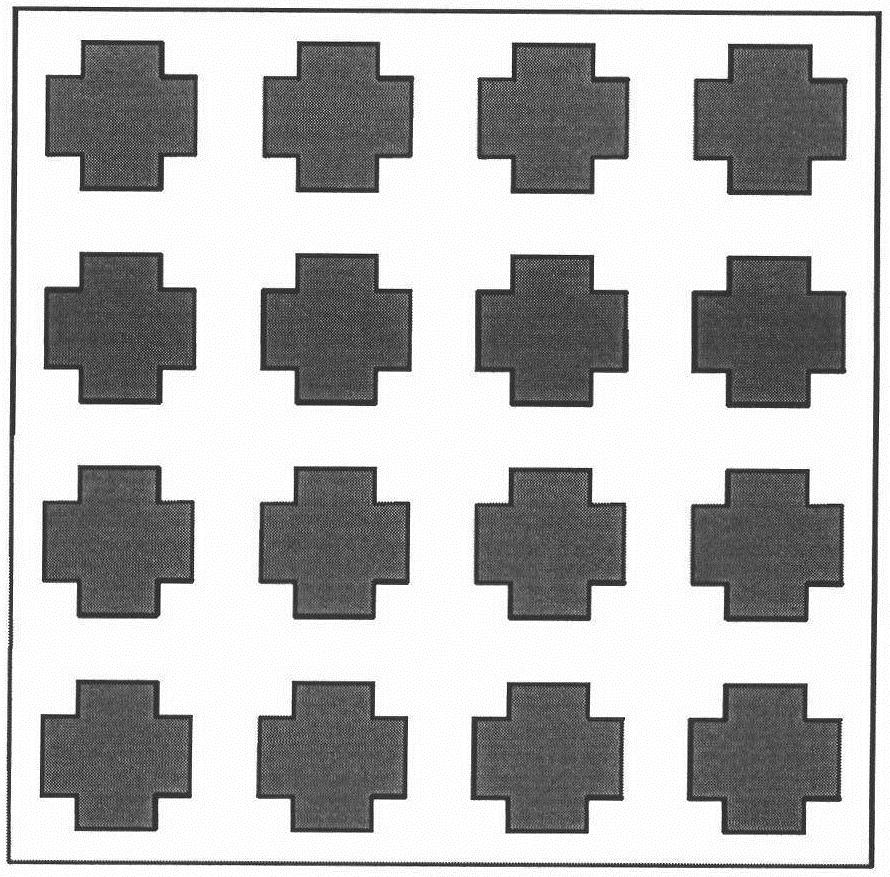

[0037] Further, the periodic structure layer is prepared on the lower surface of the composite material by etching and electroplating, and the pattern type is a cross with a side number of 12, and the material used is metal nickel, which forms a wave absorption with the electroplated metal layer. Double effect of reflection, thickness 0.5mm, see figure 2 ;

[0038] Further, the medium layer is a three-dimensional fabric reinforced ceramic matrix composite material, the wave-transmitting layer is alumina ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com