Titanium alloy titanium fireproof coating and preparation method thereof

A titanium alloy and coating technology, applied in the field of titanium alloy titanium fireproof coating and its preparation, can solve the problems of poor impact resistance, weak matrix bonding, reduced matrix fatigue performance, etc., and achieve stable coating, uniform distribution, The effect of improving the resistance to air scour

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

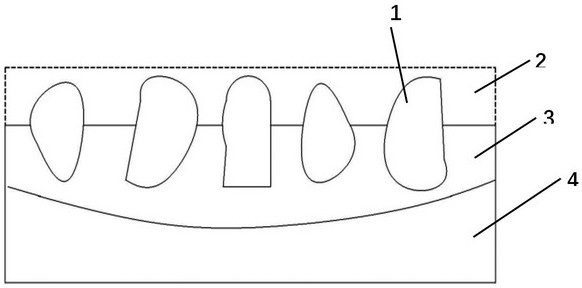

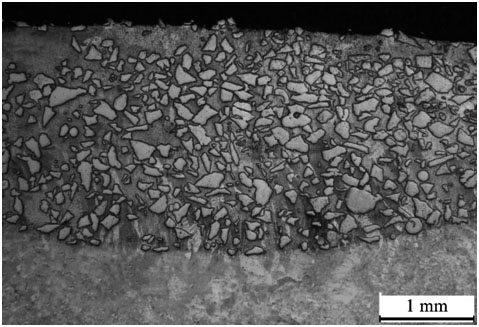

[0036] The W, Mo, Ta, Nb metal scraps (small metal pieces) are obtained by physical crushing method to obtain 10-100 mesh irregular shaped particles. The molar ratio of W, Mo, Ta and Nb is W: 25%, Mo: 25% , Ta: 25%, Nb: 25%. Then Ni, Cr, Al, Y, V, Zr are powdered by gas atomization to obtain 100-1250 mesh spherical metal powder. The molar ratio of Ni, Cr, Al, Y, V, and Zr is Ni: 50%, Cr : 10%, Al: 10%, Y: 10%, V: 10%, Zr: 10%. The irregular shaped powder and spherical metal powder are mixed in a three-dimensional mixer to obtain a uniformly mixed powder.

[0037] The substrate is sequentially roughened with 60, 120, 240, 500, 800, 1000, 2000 grit sandpaper to remove the surface oxide scale, and then cleaned with ultrasonic acetone and alcohol to remove surface stains.

[0038] The mixed powder and the solvent are mixed and then ground to obtain a powder coating, which is composed of 90% by mass of alloy powder and 10% of absolute ethanol. Grinding was carried out in a morta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com