All-solid-state metal lithium battery and preparation method thereof

An all-solid-state, metal lithium technology, applied in the manufacture of electrolyte batteries, batteries, secondary batteries, etc., can solve problems such as hidden safety hazards and flammability of polymers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A flame retardant additive, comprising the steps of:

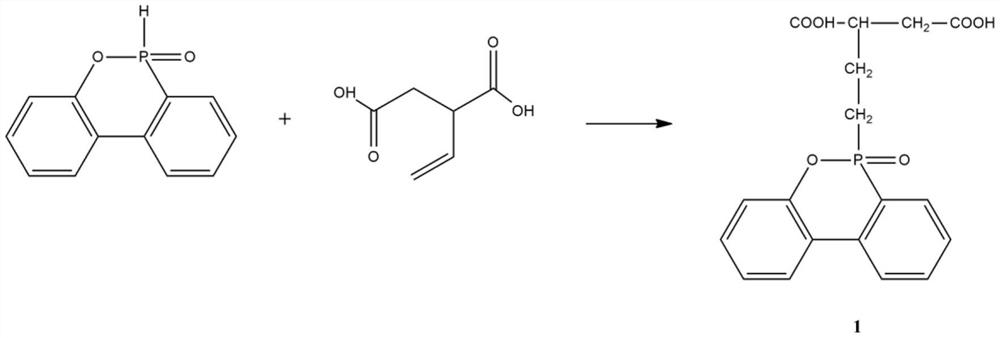

[0040] Step S11: Add o-xylene into the flask, then feed 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide with nitrogen gas at a temperature of 90°C and a speed of 400r / min Stir at low temperature for 20 minutes, then slowly add diethylene succinic acid into the flask, and after the addition is complete, reflux at 140°C for 7 hours. After the reaction, the reaction solution is cooled to room temperature, and the intermediate 1 is obtained by suction filtration;

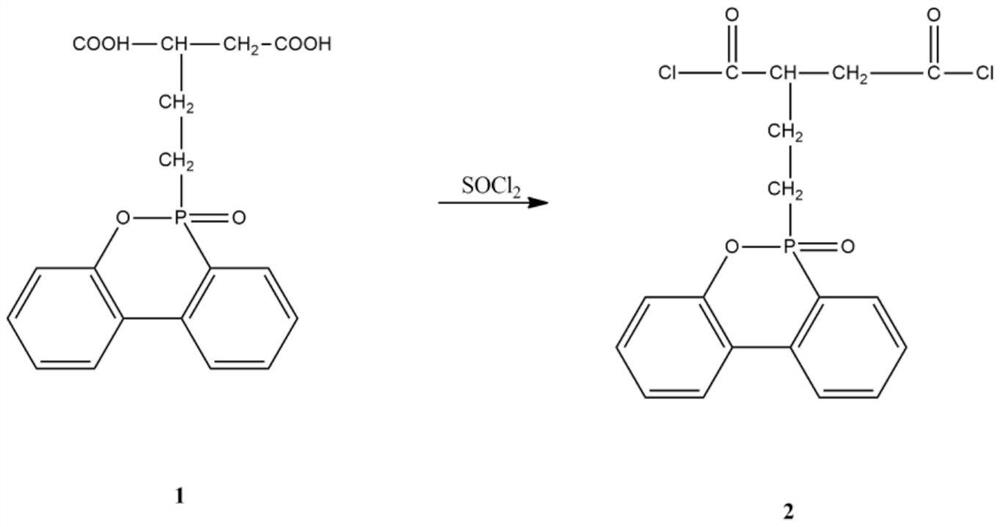

[0041] Step S12: Add the intermediate 1 prepared in step S1 into a flask filled with deionized water, stir for 20 min at a rotation speed of 400 r / min, then add thionyl chloride to it, heat up to 60° C. for reflux reaction for 9 h, and the reaction ends Afterwards, the temperature was raised to 80° C. to remove unreacted thionyl chloride, and the solvent was removed by rotary evaporation to obtain intermediate 2;

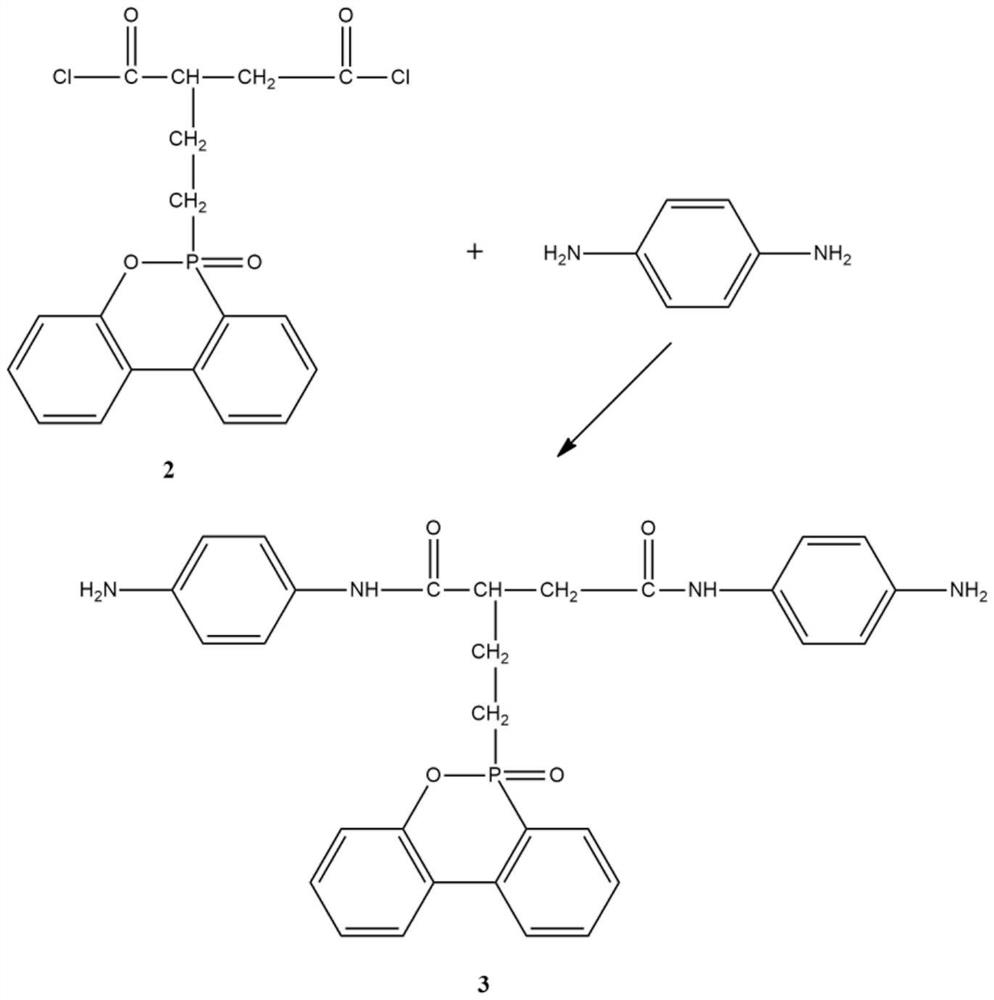

[0042] Step S13: Add dichloromethane and...

Embodiment 2

[0045] A flame retardant additive, comprising the steps of:

[0046] Step S11: Add o-xylene in the flask, then feed 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide into nitrogen gas at a temperature of 90°C and a speed of 500r / min Stir at low temperature for 25 minutes, then slowly add diethylene succinic acid into the flask, and reflux at 145°C for 7.5 hours after the addition is complete. After the reaction, the reaction solution is cooled to room temperature, and the intermediate 1 is obtained by suction filtration;

[0047] Step S12: Add the intermediate 1 prepared in step S1 into a flask filled with deionized water, stir for 20 min at a rotation speed of 400 r / min, then add thionyl chloride therein, raise the temperature to 65° C. for 9.5 h under reflux, and react After the end, the temperature was raised to 82.5°C again to remove the unreacted thionyl chloride, and the solvent was removed by rotary evaporation to obtain intermediate 2;

[0048] Step S13: Add dichloro...

Embodiment 3

[0051] A flame retardant additive, comprising the steps of:

[0052] Step S11: Add o-xylene in the flask, then feed 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide with nitrogen gas at a temperature of 90°C and a speed of 600r / min Stir at low temperature for 30 minutes, then slowly add diethylene succinic acid into the flask, and reflux at 150°C for 8 hours after the addition is complete. After the reaction, the reaction solution is cooled to room temperature, and the intermediate 1 is obtained by suction filtration;

[0053] Step S12: Add the intermediate 1 prepared in step S1 into a flask filled with deionized water, stir for 20 min at a rotation speed of 400 r / min, then add thionyl chloride to it, heat up to 70°C and reflux for 10 h, and the reaction ends Afterwards, the temperature was raised to 85° C. to remove unreacted thionyl chloride, and the solvent was removed by rotary evaporation to obtain intermediate 2;

[0054] Step S13: Add dichloromethane and triethylamin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com