External heating ultra-high temperature flange sealing performance detection system

A flange sealing and detection system technology, which is applied in fluid tightness testing, liquid tightness measurement using liquid/vacuum degree, heating element shape, etc. It can solve the problems of poor accuracy, difficulty, internal pressure monitoring and trace Difficult to detect pressure changes and other problems, to achieve the effect of good sealing and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

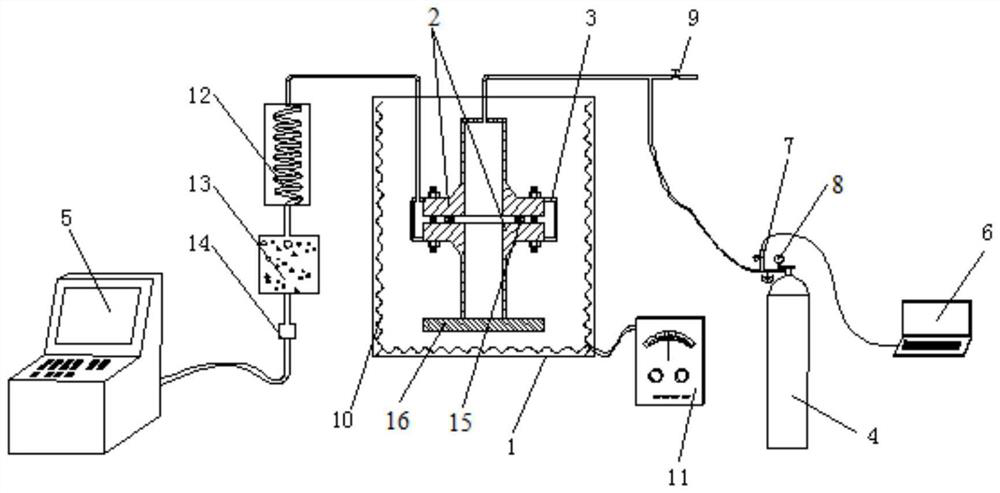

[0035] like figure 1 As shown, the present invention provides an externally heated ultra-high temperature flange sealing performance detection system, including a flange, a heating box 1, a gas supply device and a gas detection device, and a heater is fixedly installed in the heating box 1; the flange includes two Flange 2, two flanges 2 are relatively fixedly installed in the heating box 1, one end of which is fixedly connected and the interiors of the two flanges 2 are connected to each other, and the other ends are closed; one end of the two flanges 2 is outside The fixed sleeve is provided with a sealing sleeve 3, and a sealing cavity is formed between the sealing sleeve 3 and one end of the two flanges 2; the air supply device communicates with the interior of the two flanges 2 through the air inlet pipe, and the gas detection device communicates with the two flanges 2 through the air outlet pipe. The seal chamber is communicated.

[0036] During detection, a closed spac...

Embodiment 2

[0044] On the basis of Embodiment 1, in this embodiment, the gas supply device is a high-pressure helium cylinder 4 , and the gas detection device is a helium mass spectrometer 5 .

[0045]High pressure is used to directly send helium into the closed space in the two flanges 2, and helium is a colorless and odorless inert gas with inactive chemical properties. It is difficult to react with other substances under normal conditions, so as to ensure detection accuracy Normal operation; in addition, the helium mass spectrometer 5 is convenient to detect, not only can detect whether there is helium gas, but also can detect the amount of helium gas leakage, with high accuracy.

[0046] In addition to the above embodiments, other suitable inert gases, such as argon and neon, can also be used. In theory, the range from normal temperature to operating temperature (600-1000° C.) is an inert gas and can be easily detected.

Embodiment 3

[0048] On the basis of Embodiment 2, this embodiment further includes a computer 6 , a pressure sensor 7 is fixedly installed at the gas outlet of the high-pressure helium cylinder 4 , and the pressure sensor 7 is connected to the computer 6 for communication.

[0049] When detecting, the pressure at the outlet of the high-pressure helium cylinder 4 is detected by the pressure sensor 7, and the corresponding pressure signal is sent to the computer 6, and the computer 6 receives the corresponding pressure signal, which is convenient for the staff to understand the outlet of the high-pressure helium cylinder 4. real-time pressure, safe and reliable.

[0050] It should be noted that the above-mentioned computer 6 is a computer, and the pressure sensor 7 is actually connected to the controller inside the computer 6 through a line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com