On-line monitoring method for internal field temperature in milling process

A milling and milling technology, applied in the field of mechanical cutting, can solve the problem of inability to use the online monitoring of the temperature of the inner field of the tool, and achieve the effects of easy implementation, low computational complexity, and good practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention is further described below with reference to the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the embodiments are not intended to limit the present invention.

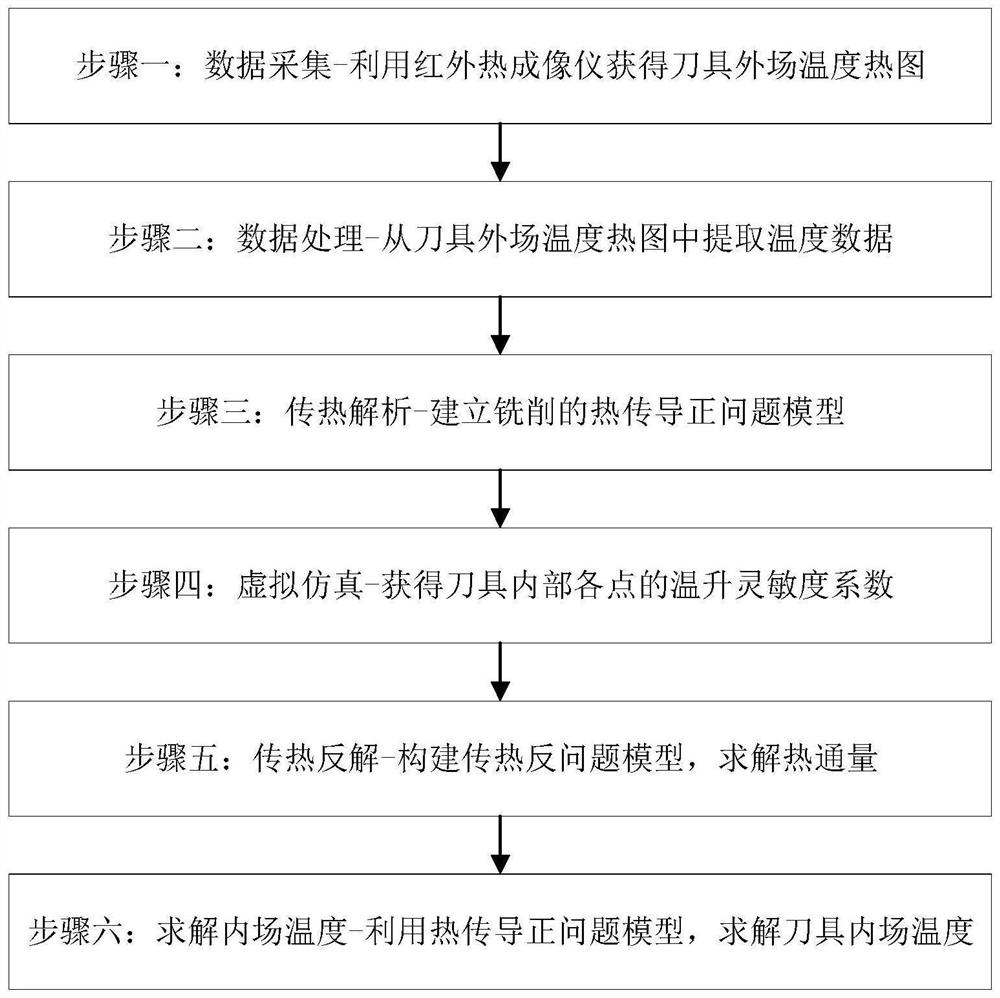

[0070] like figure 2 As shown, it is a flow chart of the on-line monitoring method of the infield temperature during the milling process of the present invention. The method for online monitoring of the internal field temperature in the milling process of the present embodiment includes the following steps:

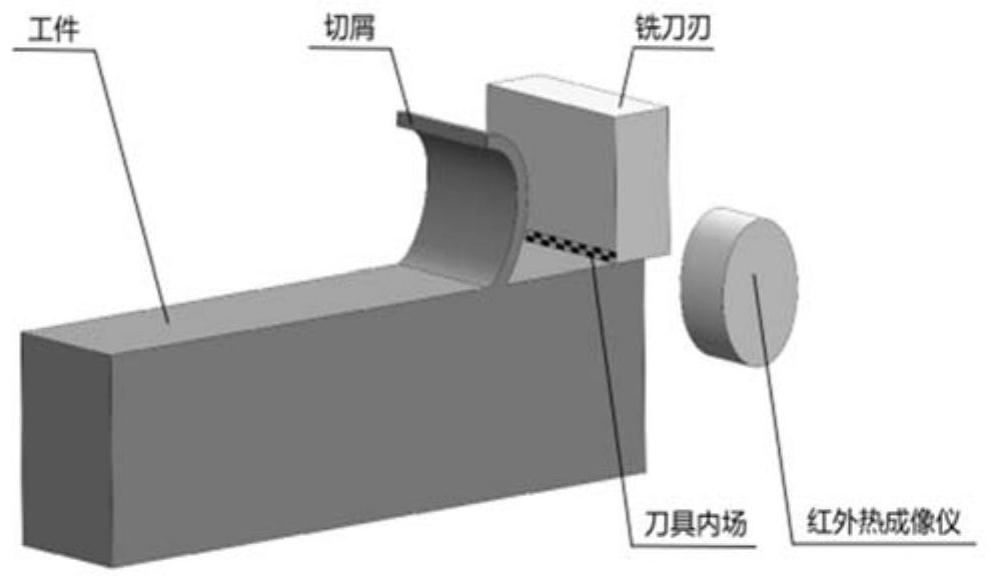

[0071] Step 1: Data acquisition: During the milling process, use an infrared thermal imager to take pictures of the tool and workpiece in real time to obtain a heat map of the tool's external field temperature for extracting the external field temperature.

[0072] The invention uses the infrared thermal imager to obtain the temperature of the external field of the tool, and uses the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com