High-reliability absolute pressure sensor and packaging method

A technology of pressure sensor and packaging method, which is applied in the direction of measuring fluid pressure, instruments, measuring devices, etc., can solve the problems of poor reliability and high cost of back absolute pressure sensor, achieve low cost, improve long-term reliability, and reduce quantity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

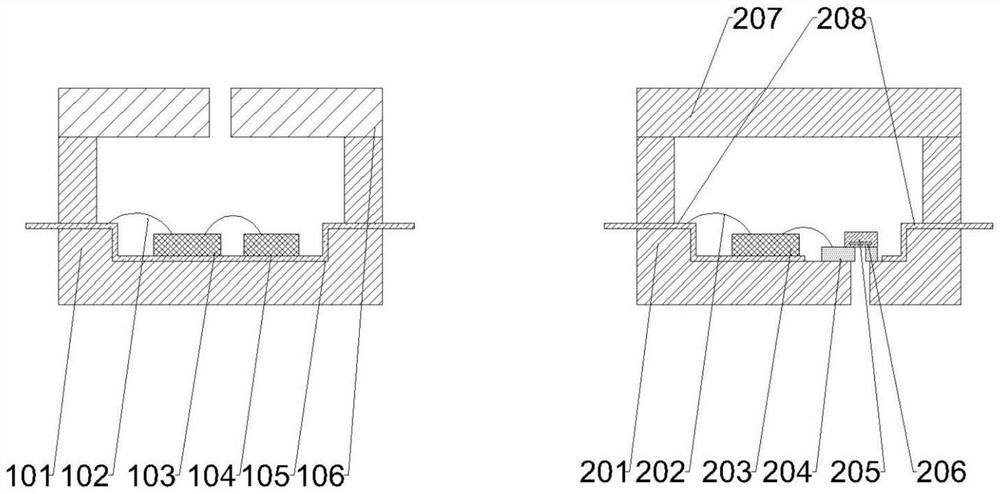

[0041] This embodiment provides a MEMS absolute pressure sensor, including: a plastic casing, a lead frame, an ASIC chip, a MEMS chip, and a metal wire;

[0042] The top of the plastic casing is open, and the lead frame is made of copper alloy, which can be copper-iron alloy, copper-nickel-silicon alloy, copper-chromium-zirconium alloy, and runs through the plastic casing; one end of the lead frame is used as an input / output terminal to connect with the outside world, and the other end Attached to the bottom and side walls of the plastic package to achieve electrical connection with MEMS and ASIC chips.

[0043] The ASIC chip faces down and is glued to the inside of the plastic casing by epoxy resin, and the contact points of the front circuit bumps are in contact with the lead frame to achieve electrical connection;

[0044] The MEMS chip is pasted on the back of the ASIC chip, and is electrically connected to the lead frame by wire bonding through metal wires;

[0045]Each ...

Embodiment 2

[0049] This embodiment provides a packaging method for a MEMS absolute pressure sensor, including the following steps:

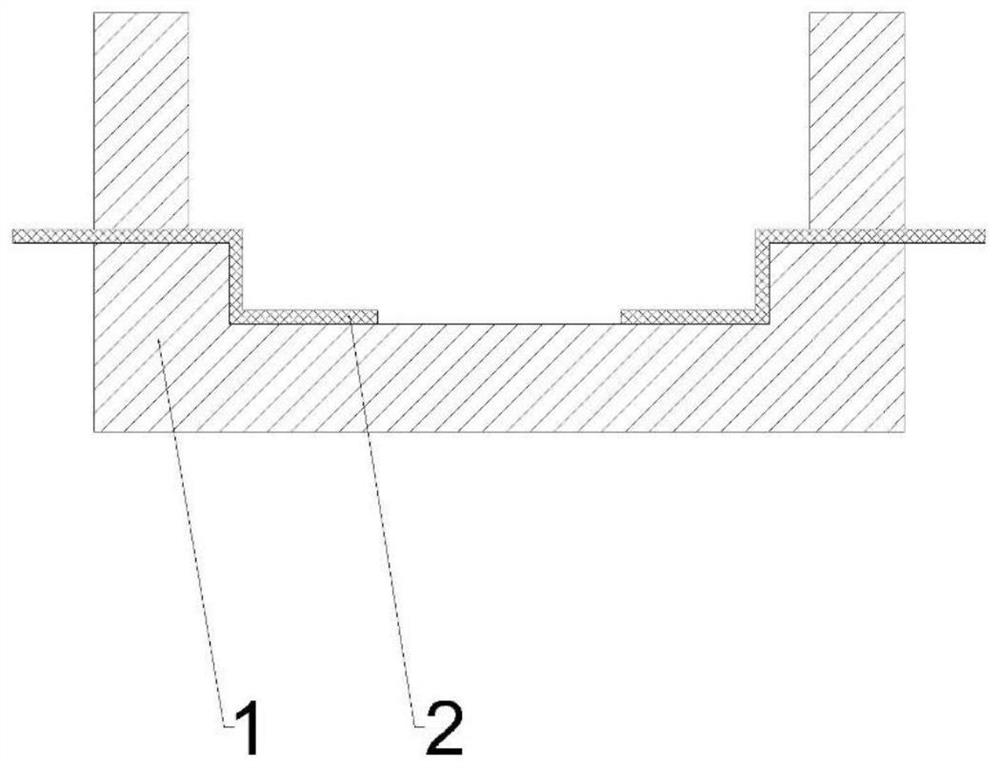

[0050] Step 1: Fabrication of plastic enclosure with lead frame;

[0051] The top of the plastic casing is open, and the lead frame is made of copper alloy, which can be copper-iron alloy, copper-nickel-silicon alloy, copper-chromium-zirconium alloy, and runs through the inside and outside of the plastic casing; one end of the lead frame outside the plastic casing serves as an input / output terminal and the outside world. connected, and one end inside the plastic package is closely attached to the bottom and sidewall of the plastic package.

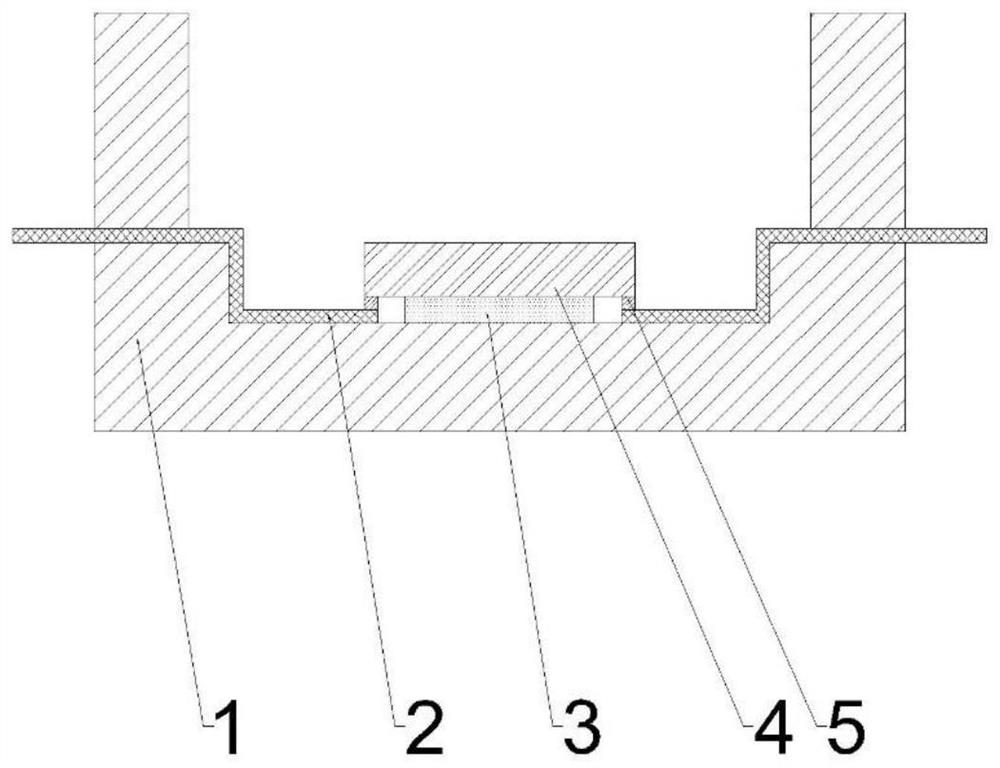

[0052] Step 2: Mount the ASIC chip:

[0053] The ASIC chip faces down and is pasted inside the plastic casing through epoxy resin glue. At the same time, the contact points of the circuit bumps on the front side of the ASIC chip are in contact with the corresponding positions on the lead frame to realize the ASIC chip. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com