Composite antifreeze agent and application thereof

A compound antifreeze technology, which is applied in the application, preservation of meat/fish and peptides through freezing/cooling, can solve the problems of quality deterioration of frozen shrimp, protect the original color, increase muscle water retention, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

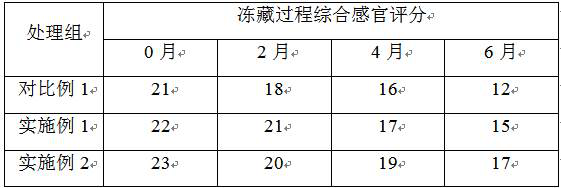

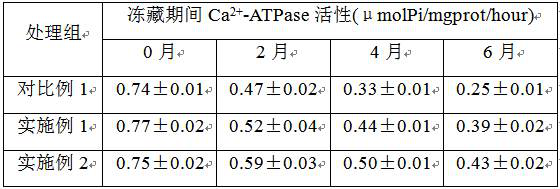

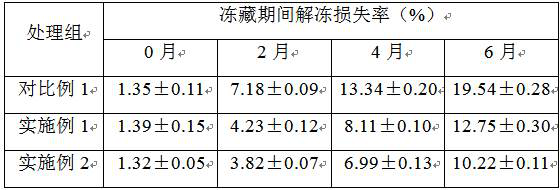

Examples

Embodiment 1

[0036] A preparation and application method of a composite antifreeze agent mainly comprises the following steps: pretreatment of fresh shrimp, preparation of fish scale antifreeze peptide, soaking in the composite antifreeze agent, freezing treatment, vacuum packaging, and cold storage storage.

[0037] (1) Pretreatment of fresh shrimp: After the fresh shrimp is caught, use crushed ice to cool down and cool to death, remove the shrimp head, shrimp shell, and shrimp line, clean it, and place it on a drain rack to drain the water to obtain fresh shrimp.

[0038] (2) Preparation of fish scale antifreeze peptide: fresh fish scales were washed with clean water for 3 times and then dried, and then pulverized by a pulverizer. The treated fish scale powder was added with 0.5mol / L hydrochloric acid for decalcification. The ratio of material to liquid: 1:10 , Decalcification time: 1h, rinse the decalcified fish scales with clean water, add deionized water, the ratio of material to liqui...

Embodiment 2

[0045] A preparation and application method of a composite antifreeze agent mainly comprises the following steps: pretreatment of fresh shrimp, preparation of fish scale antifreeze peptide, soaking in the composite antifreeze agent, freezing treatment, vacuum packaging, and cold storage storage.

[0046] (1) Pretreatment of fresh shrimp: After the fresh shrimp is caught, use crushed ice to cool down and cool to death, remove the shrimp head, shrimp shell, and shrimp line, clean it, and place it on a drain rack to drain the water to obtain fresh shrimp.

[0047] (2) Preparation of antifreeze peptides for fish scales: fresh fish scales were washed with clean water for 3 times and then dried, and then pulverized by a pulverizer. The treated fish scale powder was decalcified by adding 0.5mol / L hydrochloric acid, and the ratio of material to liquid: 1:8 , Decalcification time: 2h, rinse the decalcified fish scales with clean water and add deionized water, the ratio of material to li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com