Novel scale inhibition method of bionic super-hydrophobic surface cooperating with physical field

A super-hydrophobic surface, physical field technology, applied in vacuum evaporation coating, coating, sputtering coating and other directions, can solve the problems of environmental pollution, incomplete scale inhibition, high energy consumption, achieve green methods and reduce energy consumption , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

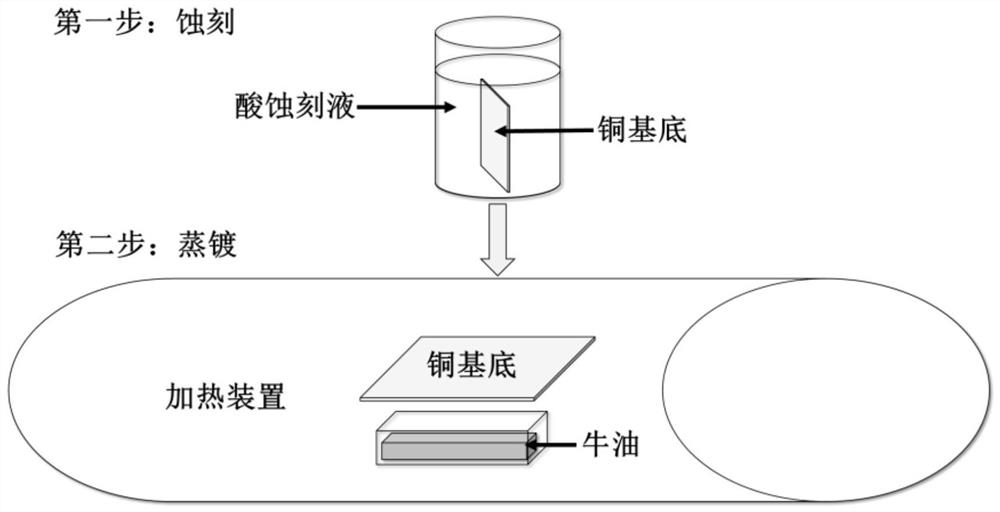

[0039] In this embodiment, a super-hydrophobic copper sheet is prepared by using a metal copper sheet as a substrate, and a novel scale-inhibiting method of bionic super-hydrophobic surface synergistic physical field includes the following steps:

[0040] (1) Take a 5cm×5cm copper sheet for sanding, rinse with ethanol after grinding and dry it for use; after drying, place the polished and rinsed copper sheet in a 1.5mol / L HCl solution at 70°C Etched for 9 min, and rinsed with ethanol after taking out to obtain a super-hydrophilic copper sheet;

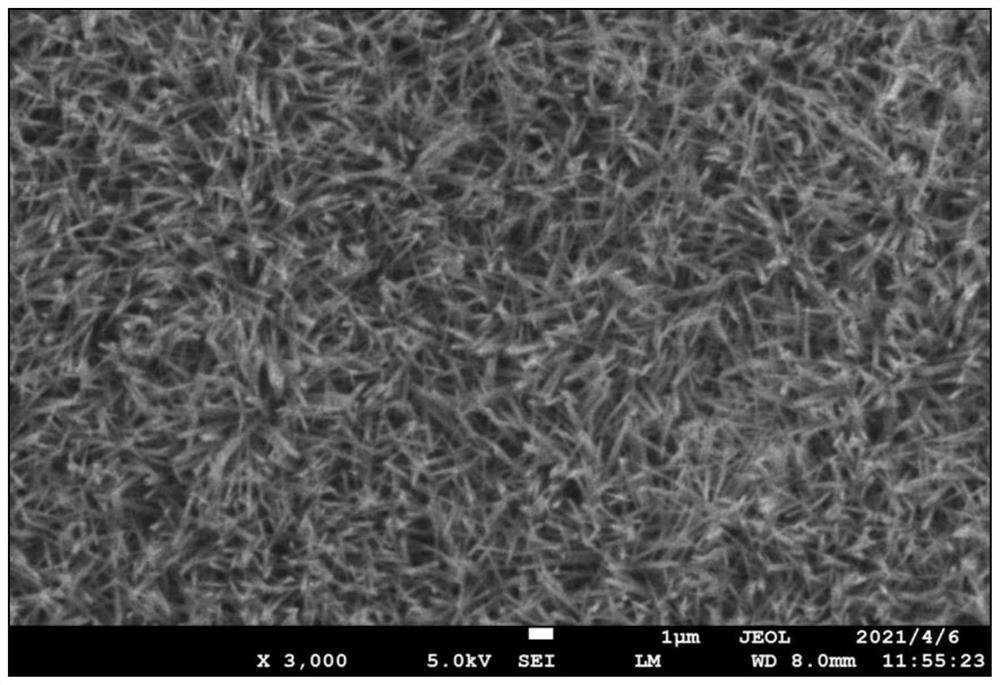

[0041] (2) place the super-hydrophilic copper sheet horizontally at 3 cm above the tallow, and then place it in a tube furnace for evaporation. After the evaporation process is completed, the tube furnace is cooled to room temperature and taken out to obtain a bionic super-hydrophobic copper sheet with low adhesion;

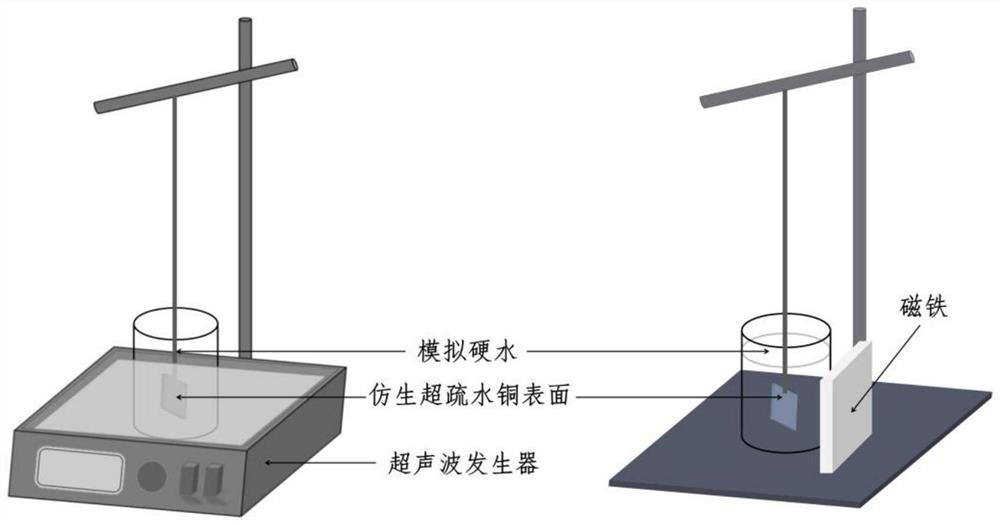

[0042] (3) The scale inhibition experiment was carried out by the hanging plate method, and 100 mL of CaCl with a conc...

Embodiment 2

[0044] In this embodiment, a super-hydrophobic copper sheet is prepared by using a metal copper sheet as a substrate, and a novel scale-inhibiting method of bionic super-hydrophobic surface synergistic physical field includes the following steps:

[0045] (1) Take a 5cm×5cm copper sheet for sanding, rinse with ethanol after grinding and dry it for use; after drying, place the polished and rinsed copper sheet in a 2.5mol / L HCl solution at 50°C Etching for 8min, after taking out, rinse with ethanol to obtain a super-hydrophilic copper sheet;

[0046] (2) The super-hydrophilic copper sheet was placed horizontally at 9 cm above the tallow, and then placed in a tube furnace for evaporation. The tube furnace was heated to 260 ° C at a heating rate of 5 ° C / min, and evaporated for 12 min. After the evaporation process is completed, the tube furnace is cooled to room temperature and taken out to obtain a bionic super-hydrophobic copper sheet with low adhesion;

[0047] (3) The scale in...

Embodiment 3

[0049] In this embodiment, a super-hydrophobic copper sheet is prepared by using a metal copper sheet as a substrate, and a novel scale-inhibiting method of bionic super-hydrophobic surface synergistic physical field includes the following steps:

[0050] (1) Take a 5cm×5cm copper sheet for sanding, rinse with ethanol after grinding and dry it for use; after drying, place the polished and rinsed copper sheet in 1.5mol / L H2O 2 SO 4 In the solution, etched at 60 °C for 8 min, taken out and rinsed with ethanol to obtain a superhydrophilic copper sheet;

[0051] (2) The super-hydrophilic copper sheet is placed horizontally at 8 cm above the tallow, and then placed in a tube furnace to carry out evaporation. After the evaporation process is completed, the tube furnace is cooled to room temperature and taken out to obtain a bionic super-hydrophobic copper sheet with low adhesion;

[0052] (3) The scale inhibition experiment was carried out by the hanging plate method, and 100 mL o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com