Manufacturing method of magnesium-aluminum metal composite structure

A metal composite structure and manufacturing method technology, applied in metal rolling, manufacturing tools, metal processing equipment, etc., can solve the problems of insufficient plastic forming ability at room temperature, poor corrosion resistance of magnesium alloys, etc., and achieve good internal interface bonding, corrosion resistance Good corrosion performance and complex shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

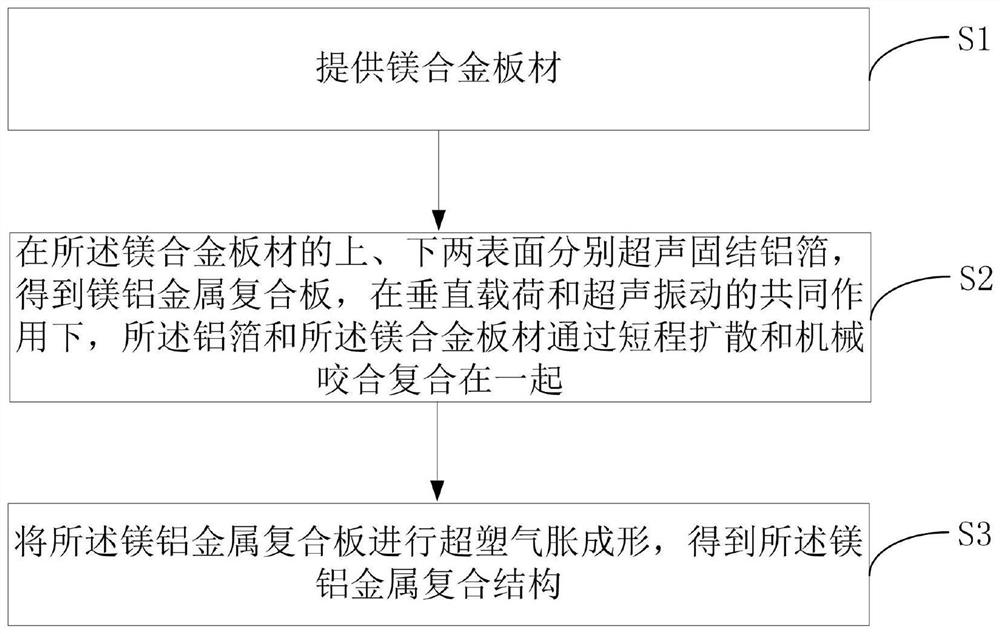

Method used

Image

Examples

Embodiment 1

[0058] 1. A fine-grained magnesium alloy sheet is prepared by the cumulative stack rolling method. The grain size of the magnesium alloy sheet is 2 μm and the thickness is 1 mm.

[0059] 2. Place the magnesium alloy plate on the ultrasonic consolidation equipment, and ultrasonically consolidate a layer of 1100 aluminum foil on one side. The thickness of the aluminum foil is 100 μm, the ultrasonic consolidation speed is 10 mm / s, the pressure is 500 kgf, and the amplitude is 10 μm.

[0060] 3. On the other side of the magnesium alloy plate, repeat the above process to ultrasonically consolidate a layer of aluminum foil or aluminum alloy foil to prepare a magnesium-aluminum metal composite plate.

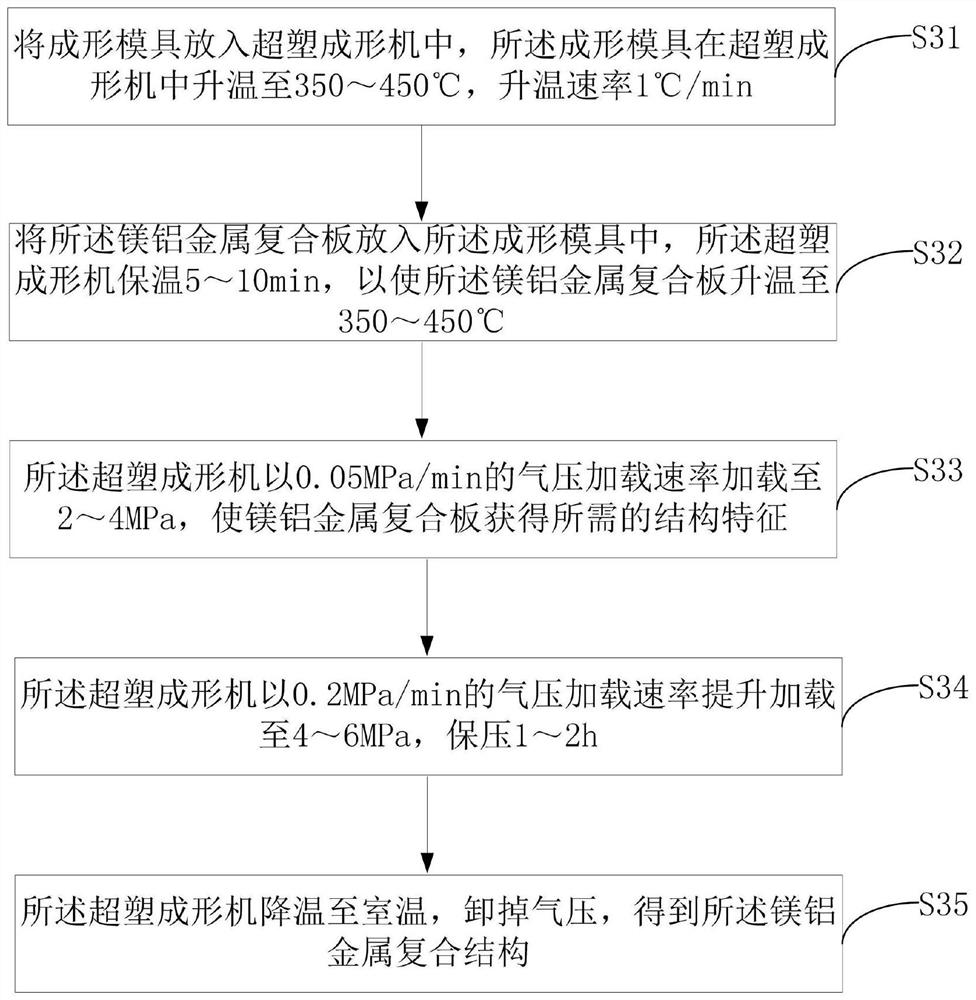

[0061] 4. Load the forming mold into the superplastic forming machine, and heat it up to 350°C with the furnace at a heating rate of 1°C / min.

[0062] 5. Turn on the superplastic forming machine, put the magnesium-aluminum metal composite plate between the upper and lower molds of the ...

Embodiment 2

[0066] 1. A fine-grained magnesium alloy plate was prepared by friction stir welding. The grain size of the magnesium alloy was 5 μm and the thickness was 4 mm.

[0067] 2. Place the magnesium alloy sheet on the ultrasonic consolidation equipment, and ultrasonically consolidate a layer of 2024 aluminum alloy foil or aluminum foil on one side. The thickness of the aluminum foil or aluminum alloy foil is 300 μm, and the ultrasonic consolidation speed is 80 mm / s. Pressure 1500kgf, amplitude 40μm.

[0068] 3. On the other side of the magnesium alloy plate, repeat the above process to ultrasonically consolidate a layer of aluminum foil or aluminum alloy foil to prepare a magnesium-aluminum metal composite plate.

[0069] 4. Load the forming mold into the superplastic forming machine, and heat up to 450°C with the furnace at a heating rate of 1°C / min.

[0070] 5. Turn on the superplastic forming machine, put the magnesium-aluminum metal composite plate into the upper mold and the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com