Method for efficiently purifying gold from alloyed gold

A high-efficiency technology for alloyed gold, which is applied in the field of high-efficiency gold purification for alloyed gold, can solve the problems of high investment cost of pulverization equipment, difficulty in cleaning materials, and long production cycle, achieving low processing costs, simple reagents, and short production cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

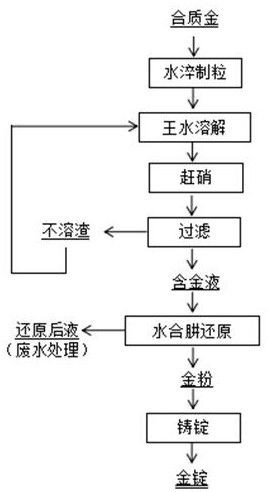

Image

Examples

Embodiment 1

[0016] Quenching the bulk alloyed gold water into gold particles with a particle size of 1mm, configure aqua regia in the titanium reaction kettle, start stirring at 50r / min, slowly add the alloyed gold particles, and add the alloyed gold particles at a speed of 6kg / min, and all the alloyed gold particles are added. Then, the stirring speed was adjusted to 100r / min, the reaction temperature was 75°C, the alloyed gold particles were all added and the reaction was completed for 20min, and the dissolution was completed; the aqua regia solution was boiled and concentrated to the original 1 / 2 volume, and 20% of the solution was added in three times. The urea solution, the volume ratio of the added amount of the urea solution to the aqua regia solution is 1:150, until there is no yellow smoke in the kettle, the nitrification is finished, filtered, and the gold-containing liquid and insoluble slag are produced, and the insoluble slag continues to return to the aqua regia solution. Dis...

Embodiment 2

[0018] Quenching the bulk alloyed gold water into gold particles with a particle size of 1.5mm, configure aqua regia in the titanium reaction kettle, start stirring at 60r / min, slowly add the alloyed gold particles at a speed of 7kg / min, and add all the alloyed gold particles. After finishing, the rotating speed was adjusted to 110r / min, the reaction temperature was 80°C, the alloyed gold particles were all added and the reaction was completed for 23min, and the dissolution was completed; the aqua regia solution was boiled and concentrated to the original 1 / 2 volume, and 22% of the solution was added in three times. Urea solution, the volume ratio of the added amount of the urea solution to the aqua regia solution is 1:120, until there is no yellow smoke in the kettle, the nitrification is finished, filtered, and the gold-containing liquid and insoluble slag are produced, and the insoluble slag continues to return to aqua regia Dissolve; add hydrazine hydrate to the gold-contai...

Embodiment 3

[0020] Quenching the bulk alloyed gold water into gold particles with a particle size of 1.5mm, configure aqua regia in the titanium reaction kettle, start stirring at 80r / min, slowly add the alloyed gold particles, and add the alloyed gold particles at a speed of 8kg / min, and add all the alloyed gold particles. After finishing, the rotating speed was adjusted to 120r / min, the reaction temperature was 85°C, the alloyed gold particles were all added and the reaction was completed for 25min, and the dissolution was completed; the aqua regia solution was boiled and concentrated to the original 1 / 2 volume, and 25% of the solution was added in three times. Urea solution, the volume ratio of the added amount of urea solution to the aqua regia solution is 1:100, until there is no yellow smoke in the kettle, the nitrification is finished, filtered to produce gold-containing liquid and insoluble slag, and the insoluble slag continues to return to aqua regia Dissolve; add hydrazine hydra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com