Carbon fiber hot press molding densification process and equipment

A technology of hot pressing and carbon fiber, which is applied in cleaning methods and utensils, chemical instruments and methods, cleaning hollow objects, etc., can solve the problems of densification methods and unsatisfactory performance of impregnating agents, shorten processing time, improve Efficiency, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further illustrated by the following examples.

[0037] A carbon fiber hot pressing forming densification process, comprising the following steps:

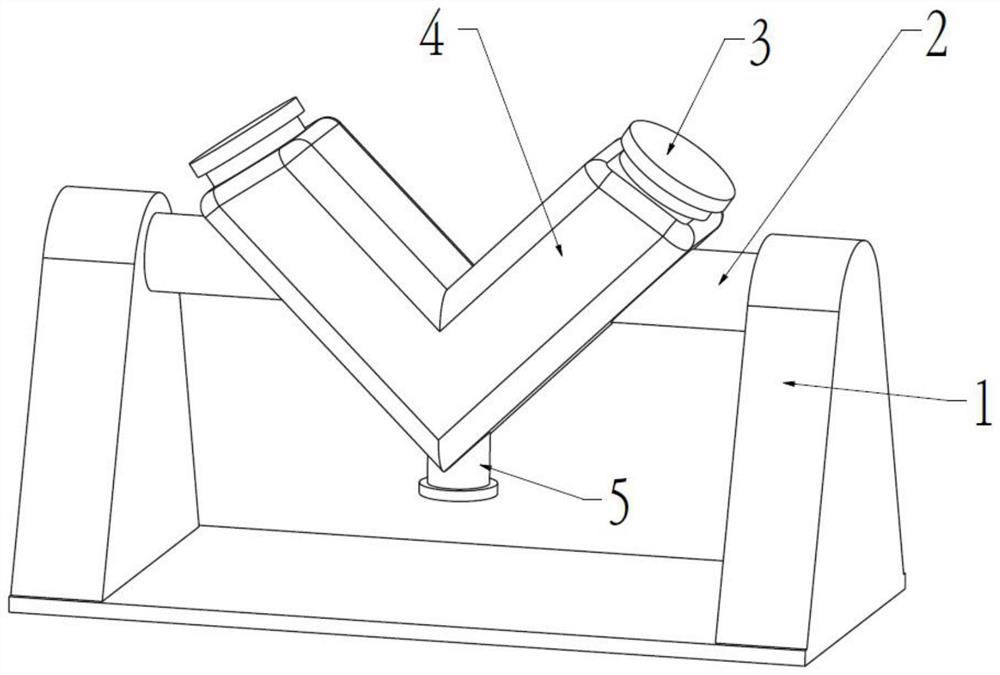

[0038] A. Mixing of raw materials: Mix short fibers, petroleum coke powder, high temperature asphalt powder and epoxy resin according to 7.5:1:1:0.5 using a V-shaped mixer;

[0039] B, hot pressing after layering: put the mixed material into the hot pressing mould for hot pressing, the hot pressing process parameters are temperature 300 ℃, duration 20-30min, the upper heating part 18 and the lower heating part 20 of the hot pressing mould All are heated by heat transfer oil, and the heat source is generated by the combustion of gas and heavy oil produced after carbonization;

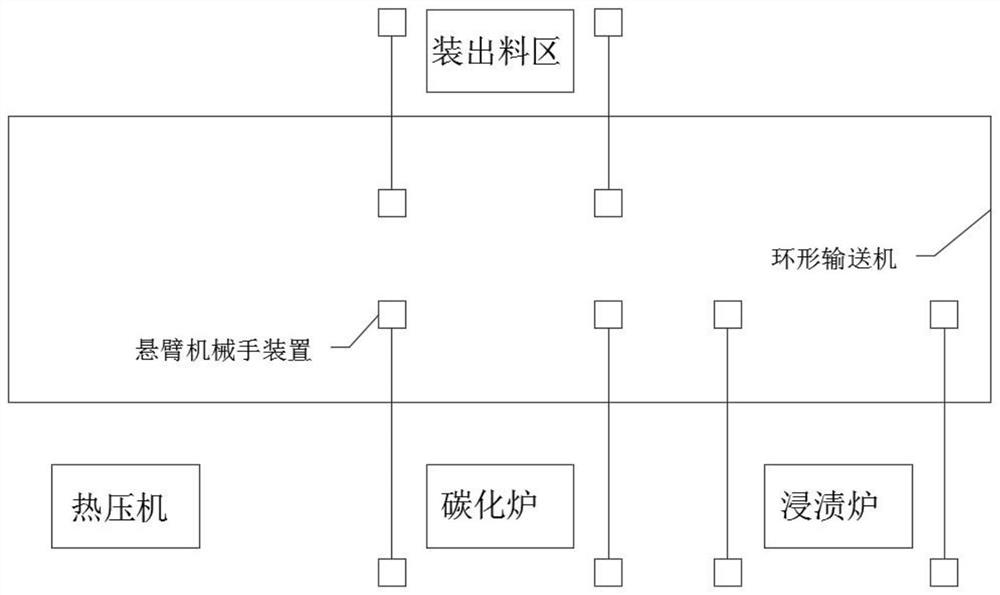

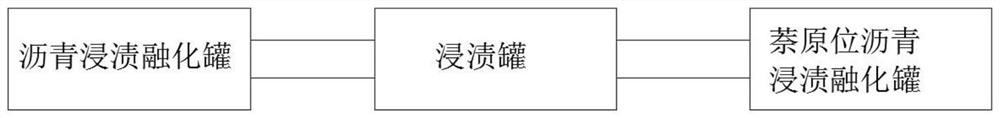

[0040] C. High temperature curing and carbonization: After reaching the carbonization furnace, put the product into the furnace through a cantilever manipulator. The high temperature curing temperature is 700℃-1400℃, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com