High-temperature and high-pressure preparation method of oxygen vacancy-containing spinel structure metal oxide negative electrode material

A spinel structure and negative electrode material technology, applied in chemical instruments and methods, structural parts, titanium compounds, etc., can solve problems that limit the development of metal oxide negative electrode materials, and achieve excellent rate performance and cycle stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A spinel structure LiCrTiO with oxygen vacancies 4 High temperature and high pressure preparation method of negative electrode material:

[0031] S1. Put Li 2 CO 3 ,TiO 2 and Cr 2 o 3 The raw materials are placed in a mortar and thoroughly ground in a molar ratio of 1 to 1.5:1:1 to achieve uniform mixing;

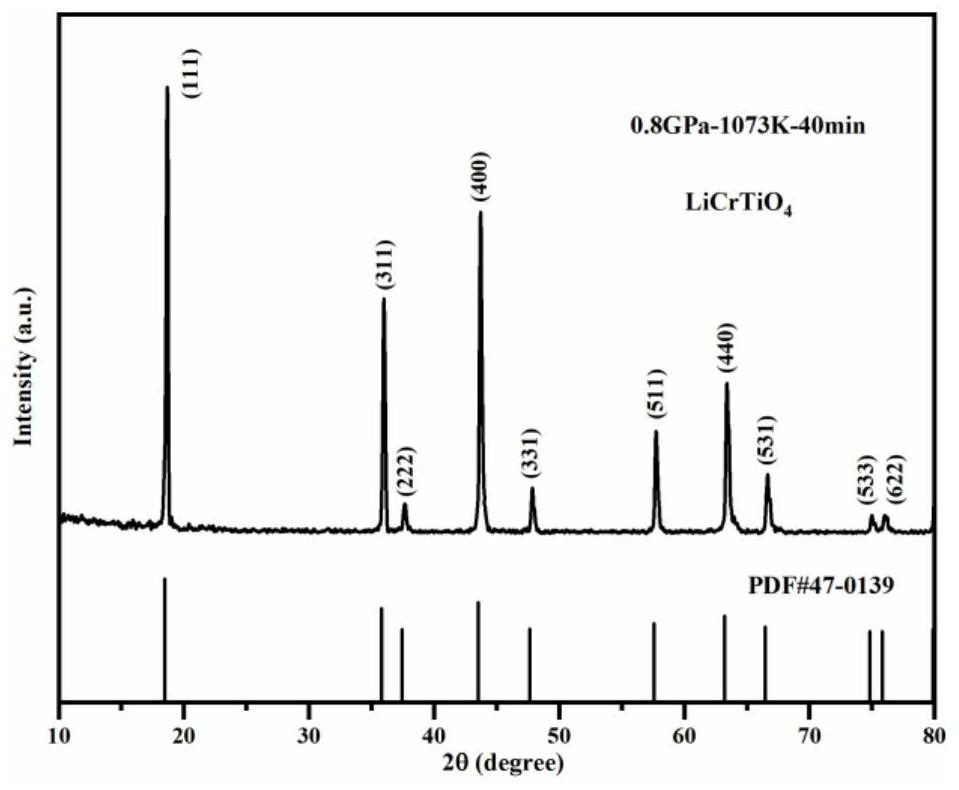

[0032] S2. Mold the uniformly mixed powder in S1, assemble and assemble into a block, and place it in the cavity of a Chinese 420-type six-sided top press, heat and hold the pressure for 40 minutes under the conditions of 0.8GPa, 1073K, and get the product containing Spinel structure LiCrTiO with oxygen vacancies 4 Negative material synthesis blocks;

[0033] S3. The spinel structure LiCrTiO containing oxygen vacancies obtained in S2 4 The negative electrode material synthesis block is crushed and ground into powder, and the spinel structure LiCrTiO containing oxygen vacancies 4 Negative electrode material synthesis blocks are mixed with deionized water and ...

Embodiment 2

[0035] A spinel structure LiCrTiO with oxygen vacancies 4 High temperature and high pressure preparation method of negative electrode material:

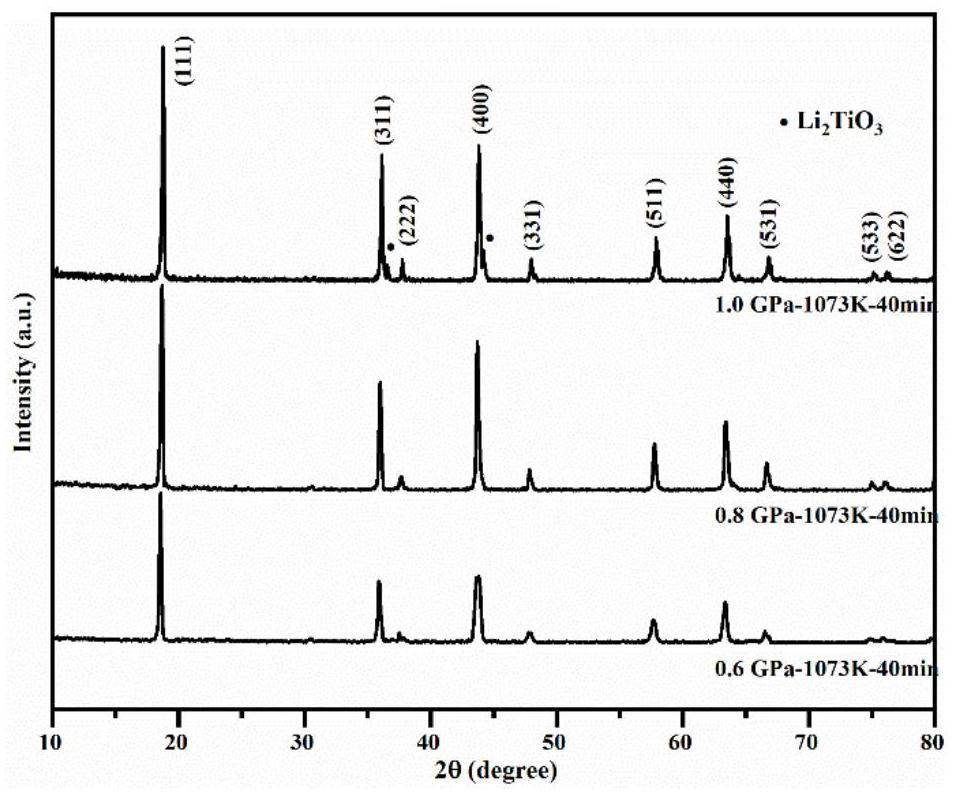

[0036] S1. Adopt the same proportioning raw material as in Example 1 and be placed in the mortar and fully grind to realize uniform mixing;

[0037] S2. The uniformly mixed powder in S1 is molded, assembled and assembled into a block, and then placed in the cavity of a Chinese 420-type six-sided top press, respectively, at a pressure of 0.6GPa, 0.8GPa and 1GPa, and a temperature of 1073K for 40 minutes. A spinel structure LiCrTiO containing oxygen vacancies was obtained after pressure relief and cooling 4 Negative material synthesis blocks;

[0038] S3. Adopt the same operation steps as S3 in Embodiment 1.

Embodiment 3

[0040] A spinel structure Li with oxygen vacancies 4 Ti 5 o 12 High temperature and high pressure preparation method of negative electrode material:

[0041] S1. Put Li 2 CO 3 ,TiO 2 Put it in a mortar and grind it fully in a molar ratio of 4 to 4.5:5 with raw materials to achieve uniform mixing;

[0042] S2. Mold the uniformly mixed powder in S1, assemble and assemble into a block, and place it in the cavity of a Chinese 420-type six-sided top press, heat and hold the pressure at 0.8GPa, 1073K for 40 minutes, and obtain a product after decompression and cooling. A kind of spinel structure Li with oxygen vacancies 4 Ti 5 o 12 Negative material synthesis blocks;

[0043] S3. Adopt the same operation steps as S3 in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com