Preparation method of Mn2O3/Mn3O4 composite electrode material for aqueous zinc ion battery

A zinc-ion battery and composite electrode technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of long synthesis time, harsh conditions, complicated steps, etc., and achieve easy control of preparation conditions and good cycle stability and the effect of rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

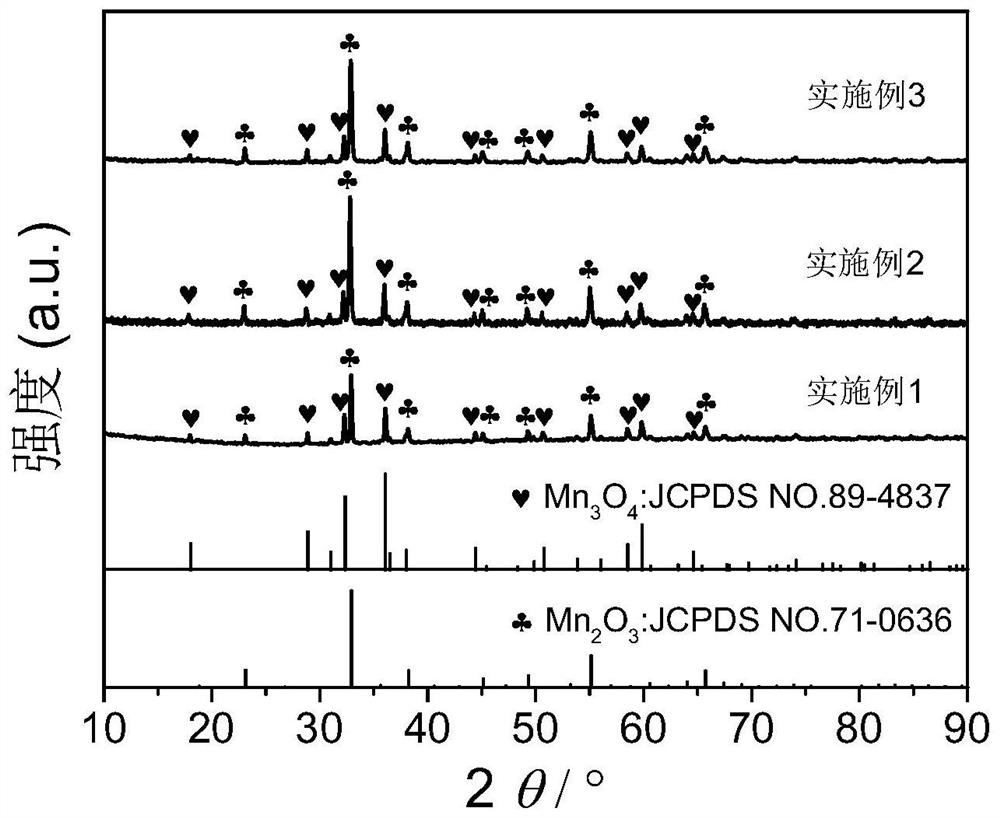

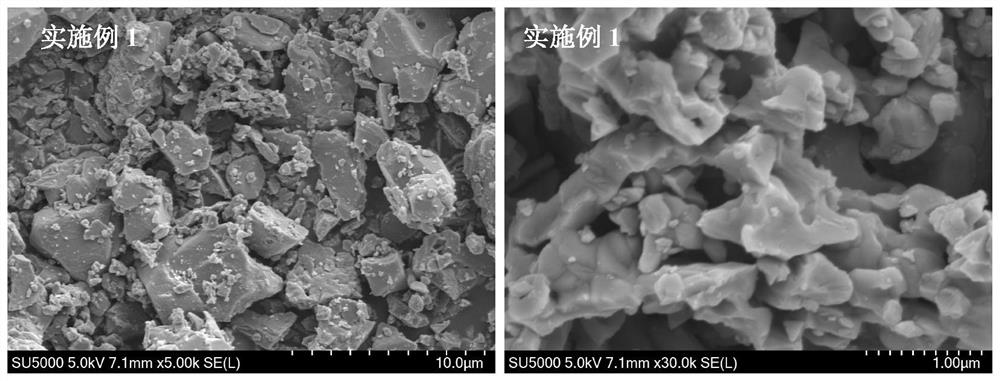

Embodiment 1

[0017] (1) According to Mn 2+ The molar ratio of sucrose and sucrose is 1:0.8, and the ratio of manganese chloride tetrahydrate (MnCl 2 4H 2 O) 1.98g and sucrose (C 12 h 22 o 11 ) 2.74 g and mixed, then 5 mL of deionized water was added to the mixture and the mixture was completely dissolved with the aid of ultrasound.

[0018] (2) Transfer the mixed solution obtained in step (1) to a crucible and place it in a muffle furnace, heat it from room temperature to 600°C at a heating rate of 5°C / min under an air atmosphere, and keep it at 600°C for 3 Hours, get manganese trioxide / trimanganese tetraoxide (Mn 2 o 3 / Mn 3 o 4 ) composite electrode material.

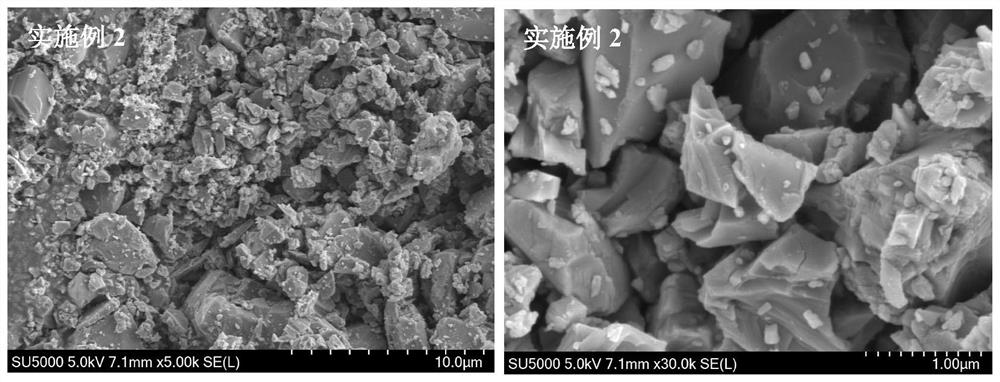

Embodiment 2

[0020] (1) According to Mn 2+ The molar ratio of sucrose and sucrose is 1:1, respectively weigh manganese chloride tetrahydrate (MnCl 2 4H 2 O) 1.98g and sucrose (C 12 h 22 o 11 ) 3.42 g and mixed, then 5 mL of deionized water was added to the mixture and the mixture was completely dissolved with the aid of ultrasound.

[0021] (2) Transfer the mixed solution obtained in step (1) to a crucible and place it in a muffle furnace, heat it from room temperature to 600°C at a heating rate of 5°C / min under an air atmosphere, and keep it at 600°C for 3 Hours, get manganese trioxide / trimanganese tetraoxide (Mn 2 o 3 / Mn 3 o 4 ) composite electrode material.

Embodiment 3

[0023] (1) According to Mn 2+ The molar ratio of sucrose and sucrose was 1:2, respectively weighed manganese chloride tetrahydrate (MnCl 2 4H 2 O) 1.98g and sucrose (C 12 h 22 o 11 ) 6.84 g and mixed, then 5 mL of deionized water was added to the mixture and the mixture was completely dissolved with the aid of ultrasound.

[0024] (2) Transfer the mixed solution obtained in step (1) to a crucible and place it in a muffle furnace, heat it from room temperature to 600°C at a heating rate of 5°C / min under an air atmosphere, and keep it at 600°C for 3 Hours, get manganese trioxide / trimanganese tetraoxide (Mn 2 o 3 / Mn 3 o 4 ) composite electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com